Welding Blanket Silicone: Ultimate Protection for High-Temperature Applications

Silicone welding blankets provide superior heat resistance and durability for welding, foundry work, and fire protection. This guide explains their benefits, applications, and how to choose the right one for your needs.

What Is a Silicone Welding Blanket?

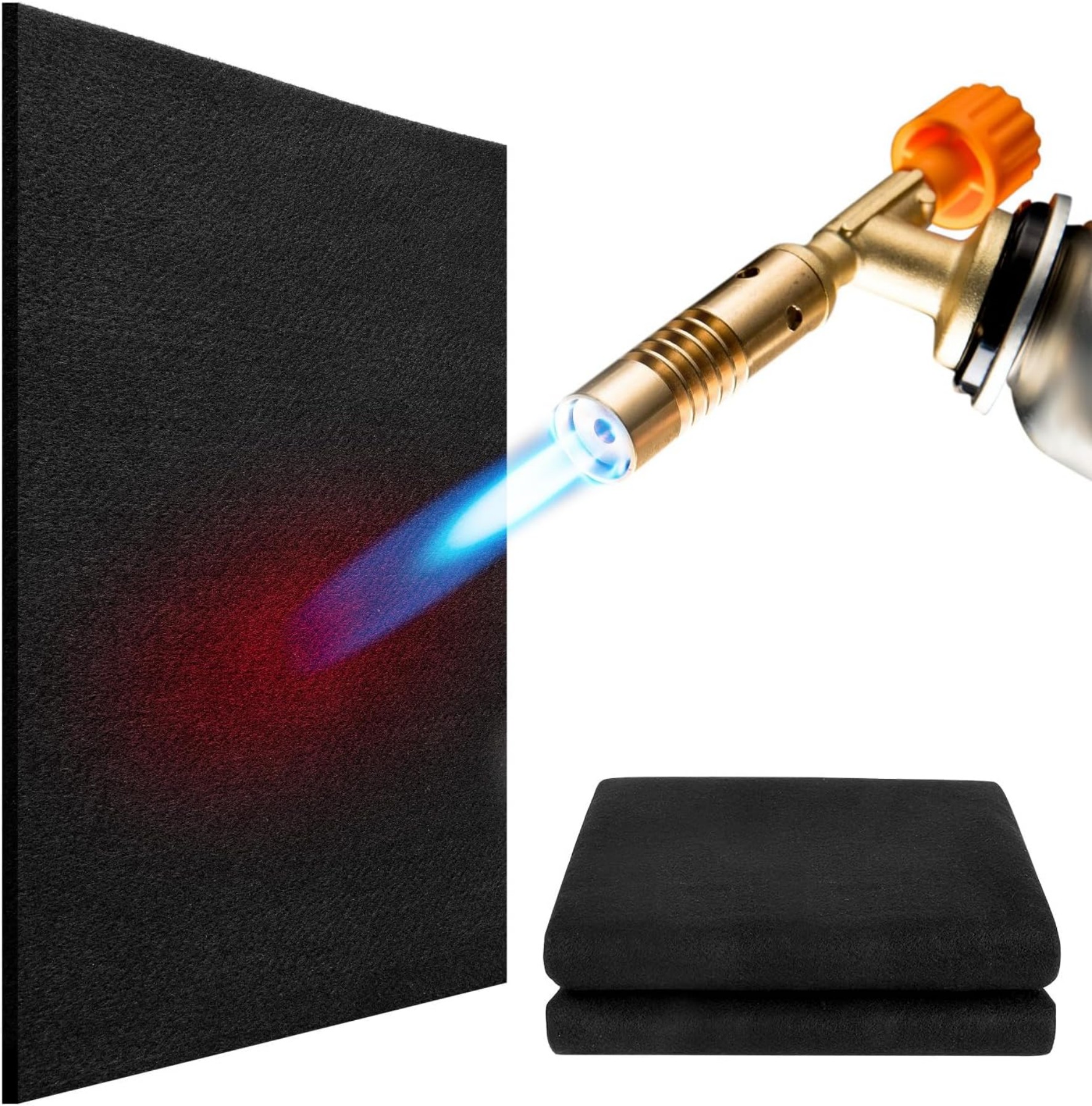

A welding blanket silicone is a flexible protective covering made from high-temperature resistant silicone-coated fiberglass. Unlike standard welding blankets, silicone versions offer exceptional resistance to sparks, molten metal splatter, and extreme heat up to 2000°F (1093°C). The silicone coating makes them more durable and easier to clean than uncoated alternatives.

Key Benefits of Silicone Welding Blankets

- Extreme heat resistance:Withstands temperatures up to 2000°F continuously

- Durability:Silicone coating resists tears and extends product life

- Flexibility:Remains pliable in cold temperatures unlike some alternatives

- Chemical resistance:Protects against oils, acids, and other industrial chemicals

- Easy maintenance:Most splatter wipes off easily from the silicone surface

- Non-conductive:Provides electrical insulation for added safety

Applications of Silicone Welding Blankets

Welding blanket silicone products are versatile across many industries:

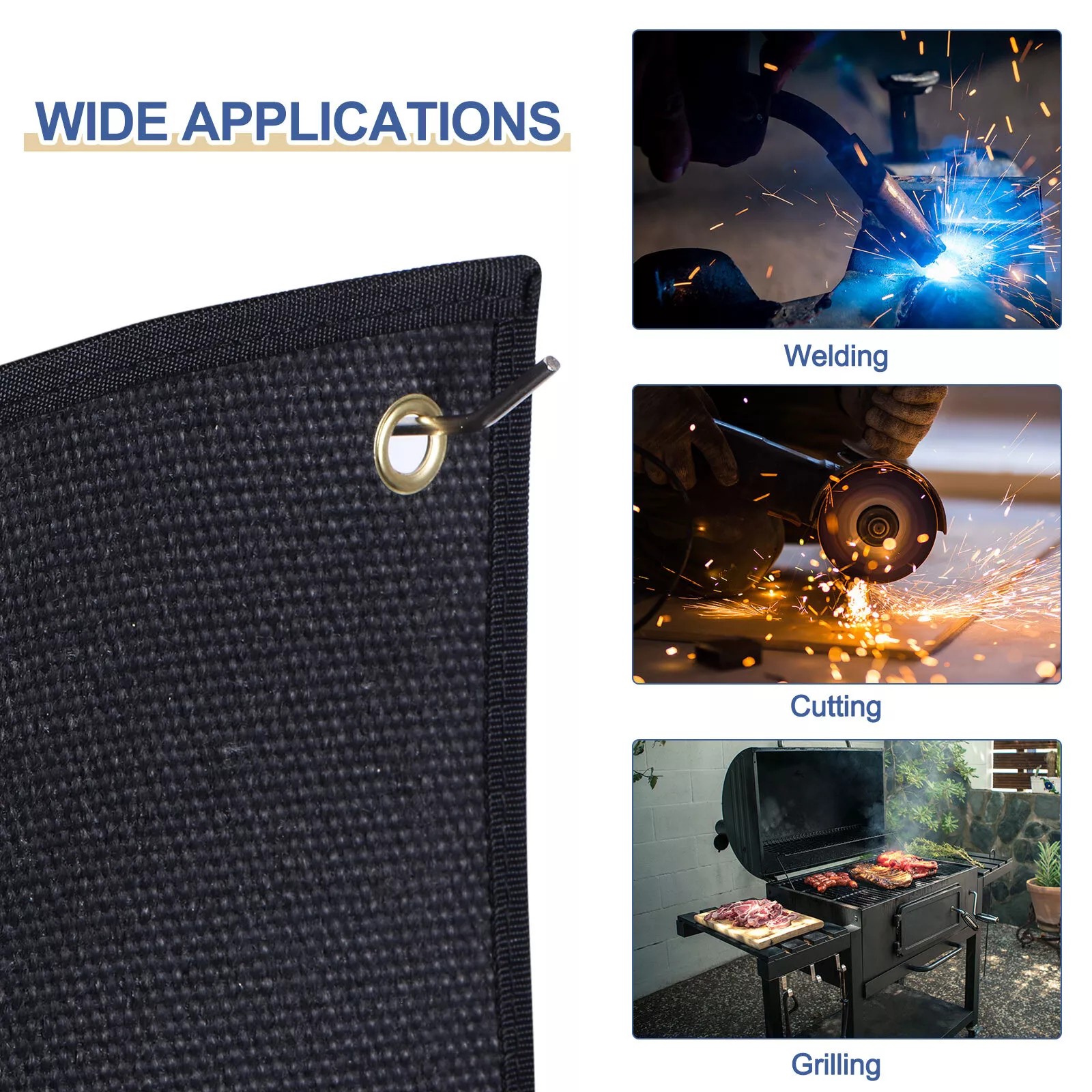

- Welding shops:Protecting floors, equipment, and nearby materials from sparks

- Foundries:Containing molten metal spills during pouring operations

- Shipbuilding:Fireproofing decks and bulkheads during hot work

- Aerospace:Protecting sensitive components during repairs

- Automotive:Shielding vehicle interiors during bodywork

- Construction:Temporary fire barriers in renovation projects

Choosing the Right Silicone Welding Blanket

Consider these factors when selecting a welding blanket silicone:

- Temperature rating:Match to your maximum working temperatures

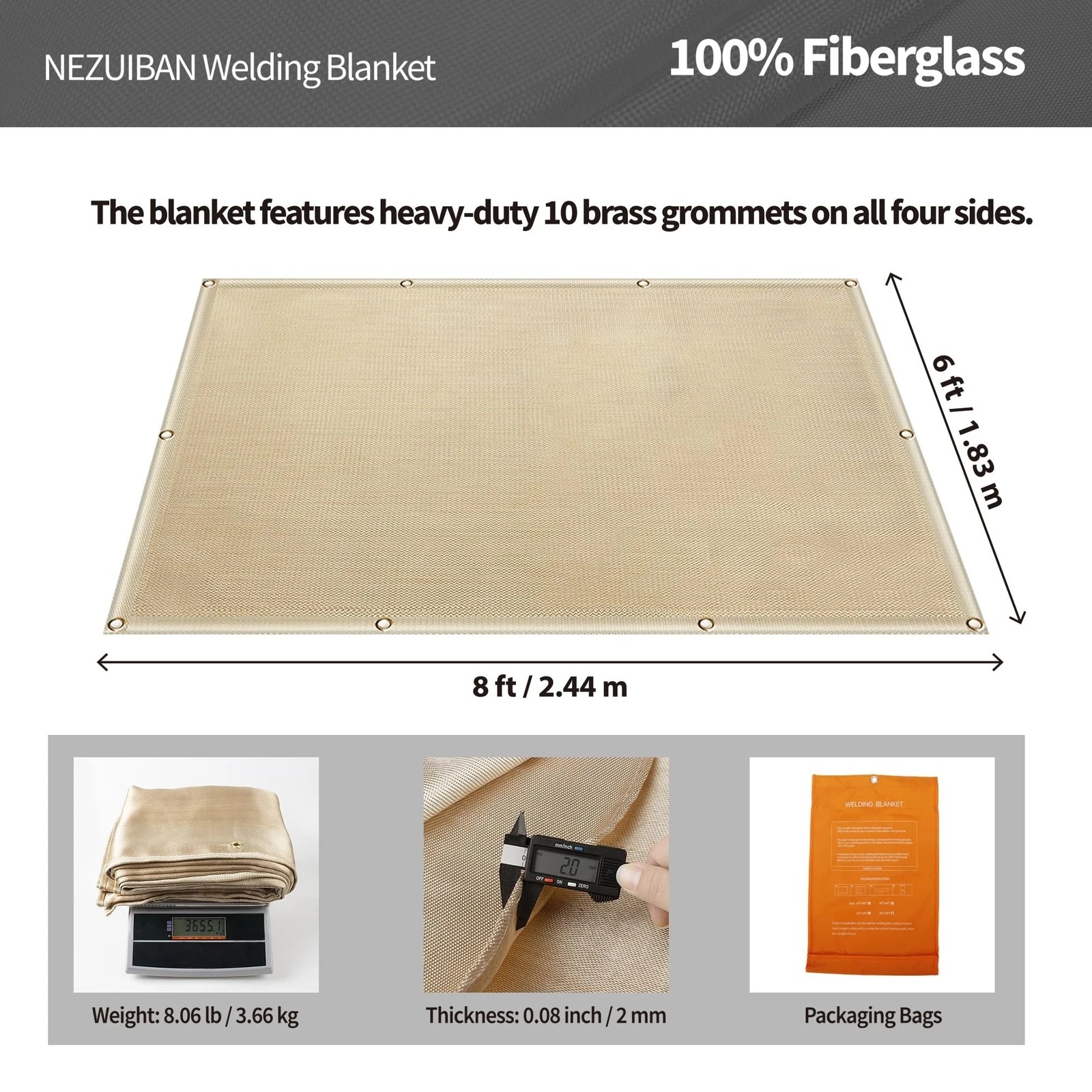

- Thickness:Thicker blankets (1/8" or more) offer better protection

- Size:Measure your work area to ensure adequate coverage

- Weight:Heavier blankets resist wind but are less portable

- Edge treatment:Look for reinforced edges with grommets for hanging

- Certifications:Check for NFPA 701 or other relevant standards

Proper Use and Maintenance

To get the most from your welding blanket silicone:

- Inspect regularly for damage before each use

- Clean with mild soap and water - avoid harsh chemicals

- Store flat or rolled - never fold as this weakens the material

- Replace when the silicone coating shows significant wear

- Never use near open flames without proper fire watch

Silicone vs. Other Welding Blanket Materials

Compared to alternatives, welding blanket silicone offers distinct advantages:

- Versus fiberglass:More durable and easier to clean

- Versus leather:Lighter and more flexible

- Versus aluminized fabrics:Better chemical resistance

- Versus treated cotton:Higher temperature tolerance

Safety Considerations

While welding blanket silicone provides excellent protection, remember:

- It's not a substitute for proper PPE like gloves and face shields

- Allow proper ventilation when working in confined spaces

- Keep at least one fire extinguisher accessible

- Train all personnel in proper use and limitations

- Follow all local regulations regarding hot work safety

Conclusion

A high-quality welding blanket silicone is an essential safety tool for any operation involving high temperatures or sparks. Its combination of heat resistance, durability, and ease of use makes it superior to many alternatives. By choosing the right product and maintaining it properly, you'll get years of reliable protection for your workspace and equipment.