Thermofelt Welding Blanket: Heat Protection for Industrial Applications

A thermofelt welding blanket is a specialized heat-resistant fabric designed to protect surfaces from sparks, slag, and extreme temperatures during welding. This guide explains its features, benefits, and how to choose the right one for your needs.

What Is a Thermofelt Welding Blanket?

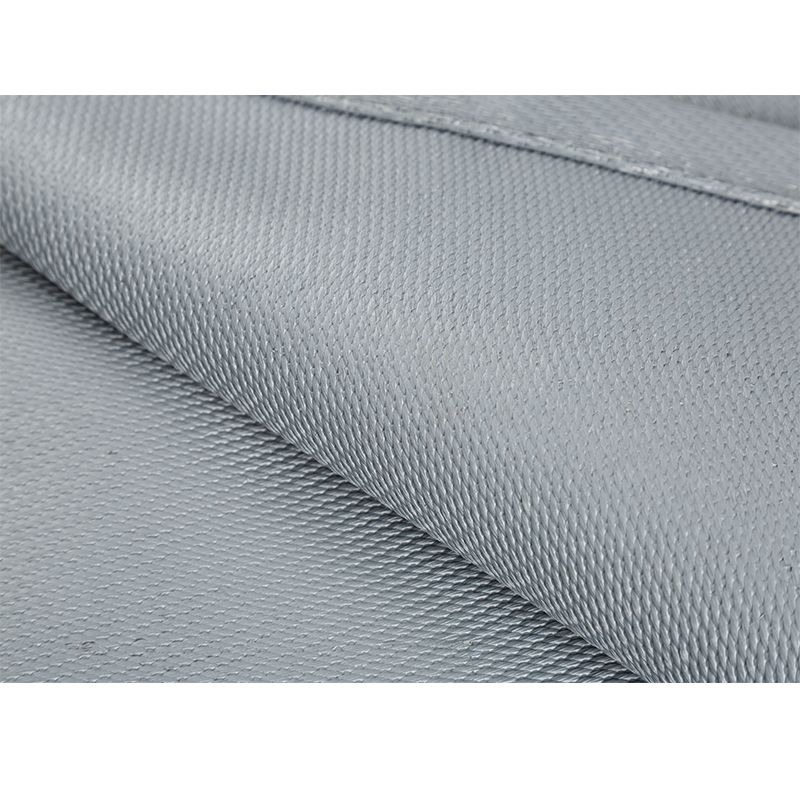

Thermofelt welding blankets are made from high-temperature resistant materials like fiberglass or silica fabric. They act as a barrier against welding sparks (up to 1,800°F/982°C) and molten metal splatter. Unlike regular tarps, they won't melt or catch fire, making them essential for welding safety.

Key Benefits of Using Thermofelt Welding Blankets

1. Fire Prevention: Their non-combustible nature prevents accidental fires in workshops.2. Surface Protection: Shield floors, machinery, or sensitive equipment from heat damage.3. Reusable: Durable construction allows multiple uses if properly maintained.4. Flexible: Can be draped over irregular shapes or used as curtains.

How to Select the Right Thermofelt Blanket

Consider these factors:- Temperature Rating: Match it to your welding process (MIG/TIG welding requires higher ratings than soldering).- Size: Larger blankets (e.g., 6'x8') cover more area but may be harder to handle.- Material: Fiberglass is cost-effective; silica offers higher heat resistance.- Thickness: Thicker blankets (1/4"+) provide better insulation but are heavier.

Proper Use and Maintenance Tips

- Always overlap blankets by 6 inches when covering large areas.- Store folded (not rolled) to prevent crease damage.- Clean with compressed air—never wash fiberglass blankets.- Inspect for tears before each use; replace if inner layers are exposed.

Common Applications Beyond Welding

Thermofelt blankets are also used for:- Foundry work (protecting floors from molten metal spills)- Fireproofing during hot work permits- Insulation for high-temperature pipes- Automotive exhaust system repairs

Safety Precautions

While thermofelt welding blankets reduce risks, always:1. Wear proper PPE (gloves, goggles)2. Ensure good ventilation3. Keep flammable materials away4. Never leave hot blankets unattended

Comparing Thermofelt to Alternatives

- Leather Welding Pads: More expensive but better for small, precise areas.- Ceramic Blankets: Higher temperature resistance but brittle and costly.- Asbestos Blankets: Older technology—avoid due to health risks.

Where to Buy Quality Thermofelt Welding Blankets

Look for suppliers that provide:- ASTM or OSHA compliance certifications- Clear temperature ratings- Reinforced edges (prevents fraying)Industrial safety stores or specialized welding retailers often offer the best options.

Investing in a proper thermofelt welding blanket protects your workspace and complies with safety regulations. Choose based on your specific needs, and maintain it well to ensure long-term performance.