Non Fiberglass Welding Blanket: Safer Heat Protection Alternatives

This article explains why non fiberglass welding blankets are safer alternatives, their materials, benefits, and how to choose the right one for your welding projects without health risks.

Why Choose Non Fiberglass Welding Blankets?

Traditional fiberglass welding blankets release tiny particles that can irritate your skin, eyes, and lungs. Non fiberglass options eliminate these health hazards while providing equal or better protection. They're made from materials like silica, ceramic, or treated wool that don't shed harmful fibers.

Key Materials in Non Fiberglass Welding Blankets

Modern non fiberglass welding blankets use several advanced materials:

- Silica Fabric:Withstands temperatures up to 1800°F (982°C) without degrading

- Ceramic Fiber:Excellent insulation with maximum temperature resistance

- Treated Wool:Natural fiber option that's self-extinguishing

- Carbon Fiber:Lightweight yet extremely durable for repeated use

Benefits Over Traditional Fiberglass Blankets

When you switch to a non fiberglass welding blanket, you gain multiple advantages:

- No airborne particles that cause respiratory issues

- Reduced skin irritation during handling

- Often more durable with longer lifespan

- Better flexibility in cold conditions

- Easier to clean and maintain

How to Select the Right Non Fiberglass Welding Blanket

Consider these factors when choosing your blanket:

- Temperature Rating:Match it to your typical welding temperatures

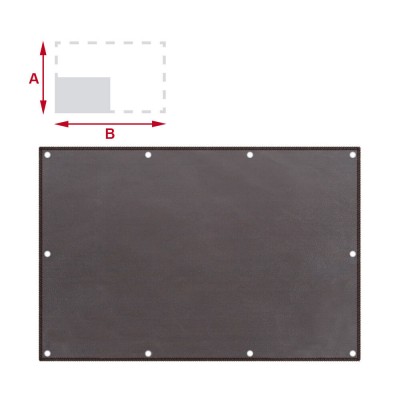

- Size:Ensure coverage for your work area with some overlap

- Weight:Lighter options are easier to handle but check durability

- Certifications:Look for OSHA or other safety certifications

- Edge Treatment:Reinforced edges prevent fraying

Proper Use and Maintenance

To get the most from your non fiberglass welding blanket:

- Inspect regularly for damage or wear

- Clean according to manufacturer instructions (usually shaking or vacuuming)

- Store flat or rolled, not folded, to prevent crease damage

- Replace when you notice significant thinning or holes

Common Applications Beyond Welding

These versatile blankets also work well for:

- Foundry work and metal casting

- Fireproofing in industrial settings

- Heat shielding in automotive applications

- Protective curtains in manufacturing

Environmental and Health Considerations

Non fiberglass welding blankets are better for both your health and the environment. They don't release microplastics or irritants into your workspace. Many options are also recyclable at end of life, unlike fiberglass which often ends up in landfills.

Cost Comparison and Value

While non fiberglass welding blankets may cost 10-20% more initially, their longer lifespan and reduced health risks often make them more economical long-term. You'll spend less on replacements and potentially avoid medical issues from fiber exposure.

Where to Buy Quality Non Fiberglass Welding Blankets

Look for reputable industrial safety suppliers or welding equipment specialists. Check product specifications carefully to ensure genuine non fiberglass construction. Leading brands now offer these safer alternatives alongside traditional options.

By choosing a non fiberglass welding blanket, you protect both your projects and your health. The slightly higher initial investment pays off in safety, comfort, and long-term value for your welding work.