High-Performance Carbon Fiber Welding Blanket Three Layer: Ultimate Heat Protection

Summary:A carbon fiber welding blanket three layer offers superior heat resistance, durability, and flexibility for welding, foundries, and high-temperature applications. This guide explains its features, benefits, and how to choose the right one.

What Is a Carbon Fiber Welding Blanket Three Layer?

A carbon fiber welding blanket three layer is a specialized protective cover made of three distinct layers of carbon fiber fabric. It is designed to withstand extreme heat, sparks, and molten metal splashes during welding, grinding, or other high-temperature tasks. The three-layer construction enhances durability and heat resistance while remaining lightweight and flexible.

Key Features of a Three-Layer Carbon Fiber Welding Blanket

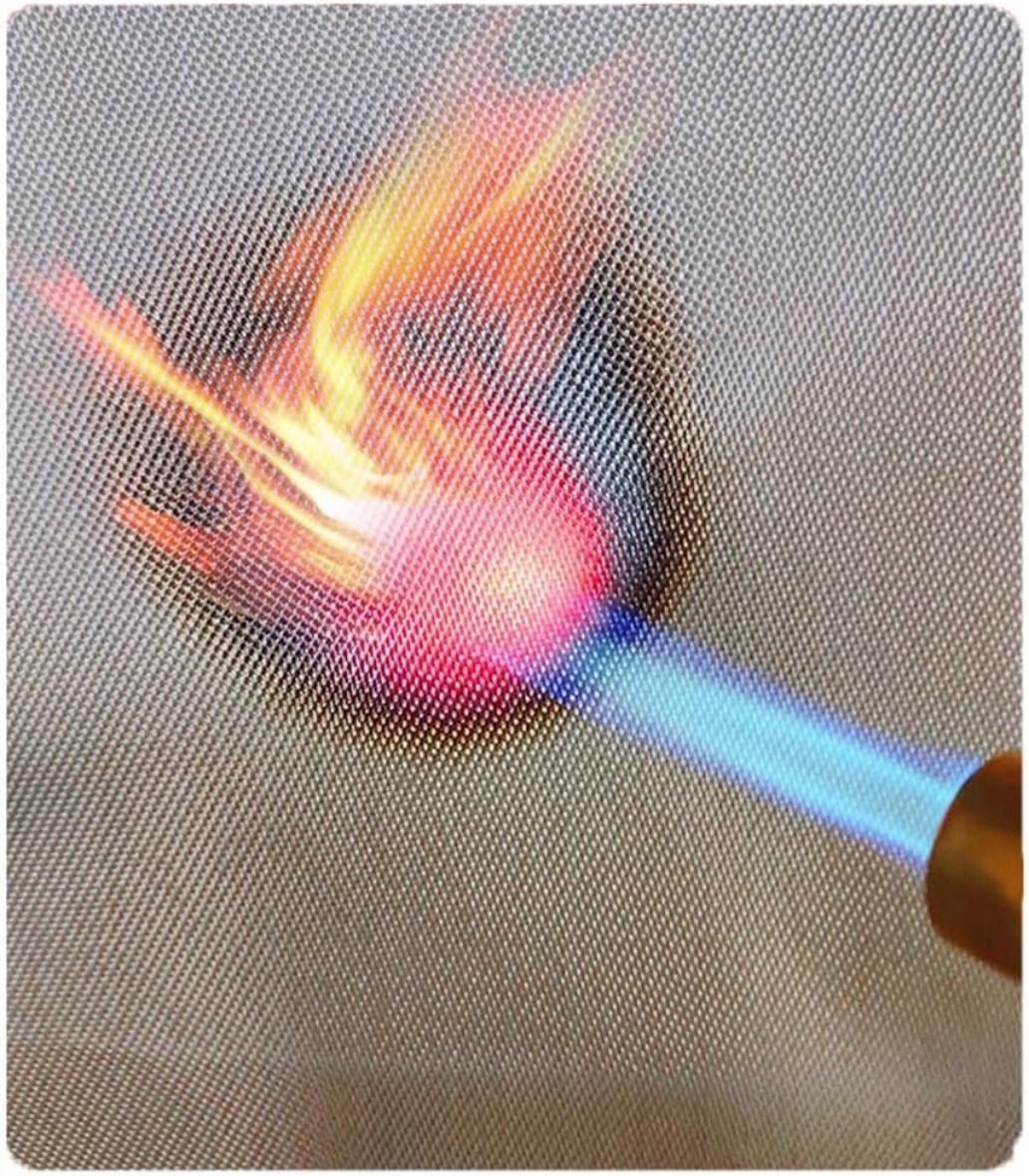

1. Extreme Heat Resistance:These blankets can endure temperatures up to 2000°F (1093°C), making them ideal for welding and metalworking.

2. Three-Layer Reinforcement:The layered design improves strength and prevents heat penetration, ensuring long-term protection.

3. Lightweight & Flexible:Unlike traditional fiberglass blankets, carbon fiber versions are easier to handle and mold around surfaces.

4. Non-Combustible:They resist flames and sparks, reducing fire hazards in workshops.

Why Choose a Three-Layer Carbon Fiber Welding Blanket?

If you work in welding, metal fabrication, or foundries, a carbon fiber welding blanket three layer provides unmatched safety and efficiency. Its multi-layer construction ensures better insulation, while the carbon fiber material resists wear and tear. Unlike single-layer alternatives, it lasts longer under heavy use.

Applications of Carbon Fiber Welding Blankets

- Welding & Grinding:Protects nearby surfaces from sparks and slag.

- Foundry Work:Shields floors and equipment from molten metal spills.

- Automotive & Aerospace:Used in heat-sensitive assembly processes.

- Fire Safety:Acts as a heat barrier in emergency scenarios.

How to Select the Right Carbon Fiber Welding Blanket

1. Temperature Rating:Ensure it matches your working conditions (e.g., 1500°F vs. 2000°F).

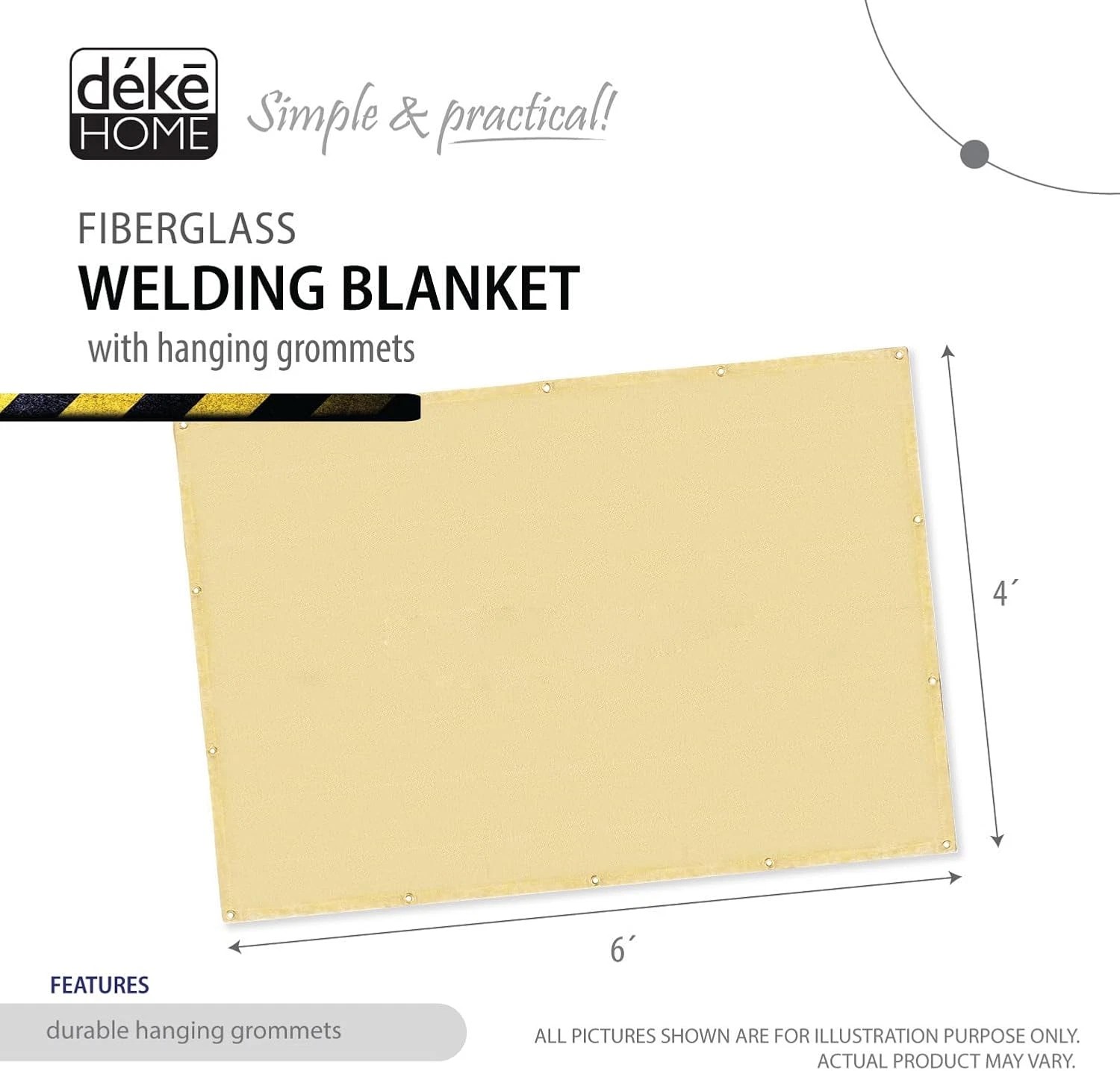

2. Size & Thickness:Larger blankets cover more area; thicker ones provide better insulation.

3. Durability:Check for reinforced stitching and high-quality fibers.

4. Flexibility:A pliable blanket is easier to position around complex shapes.

Maintenance Tips for Longevity

To extend the life of your carbon fiber welding blanket three layer, avoid folding it sharply—roll instead. Clean off metal debris regularly, and store it in a dry, cool place. Inspect for tears or thinning areas periodically.

Conclusion

A carbon fiber welding blanket three layer is a must-have for professionals dealing with extreme heat. Its superior protection, durability, and ease of use make it a smart investment. Choose the right size and rating for your needs, and follow proper care to maximize its lifespan.