Top Welding Blankets Supplier Guide - Quality & Safety Solutions

Summary:This guide helps you find reliable welding blankets suppliers, explaining key features, materials, and selection criteria to ensure workplace safety during welding operations.

Why You Need a Trusted Welding Blankets Supplier

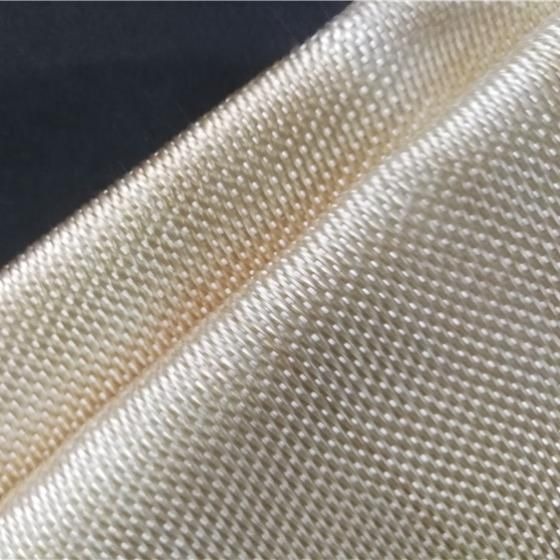

When you're working with high-temperature processes, quality welding blankets protect your workspace from sparks, slag, and heat damage. A professional welding blankets supplier provides products that meet safety standards and withstand extreme conditions. Unlike regular fabrics, these specialized blankets resist temperatures up to 3,000°F while remaining flexible.

Key Features to Look for in Welding Blankets

Your welding blankets supplier should offer products with these essential characteristics:

- Heat resistance:Minimum 1,500°F rating for general welding, higher for specialized applications

- Durability:Reinforced edges and tear-resistant materials

- Size options:From small patch blankets to large curtain systems

- Compliance:Meets OSHA and ANSI safety standards

- Material choices:Fiberglass, silica, or ceramic fiber options

How to Choose Your Welding Blankets Supplier

Selecting the right welding blankets supplier involves more than just comparing prices. Consider these factors:

- Industry experience:Suppliers with 5+ years in welding safety understand real-world needs

- Product testing:Ask for temperature resistance certificates

- Custom solutions:Some suppliers offer made-to-order sizes and shapes

- Lead times:Ensure they can meet your project deadlines

- Customer support:Technical advice should be available

Common Applications for Welding Blankets

A quality welding blankets supplier serves multiple industries with these applications:

- Construction sites:Protecting flammable materials during steelwork

- Manufacturing plants:Shielding equipment near welding stations

- Shipbuilding:Containing sparks in confined spaces

- Automotive repair:Preventing damage to vehicle interiors

- Pipeline work:Field welding protection in remote locations

Maintenance Tips from Welding Blankets Suppliers

Proper care extends your blanket's lifespan. Reputable welding blankets suppliers recommend:

- Shake off slag deposits after each use

- Store folded or rolled in dry conditions

- Inspect for tears before each use

- Clean with compressed air, never water

- Replace when fiberglass layers become brittle

Cost Considerations When Selecting a Supplier

While price matters, the best welding blankets supplier balances cost with:

- Product longevity (cheaper blankets often need frequent replacement)

- Safety certifications (non-compliant products risk violations)

- Bulk purchase discounts for large operations

- Shipping costs for heavy-duty blankets

Emerging Trends in Welding Blanket Technology

Forward-thinking welding blankets suppliers now offer:

- Eco-friendly silica materials with lower health risks

- Quick-release hanging systems for easy deployment

- Multi-layer designs combining heat and chemical resistance

- RFID tags for equipment tracking in large facilities

By understanding these aspects, you'll make informed decisions when partnering with a welding blankets supplier. Always prioritize safety certifications and real-world performance over initial cost savings to protect both your workers and equipment effectively.