Weld Blanket Guide: Protection Solutions for Safe Welding Operations

Weld blankets protect surfaces from sparks, slag, and heat during welding. This guide explains their materials, uses, selection criteria, and maintenance. You'll learn how weld blankets improve safety and prevent costly damage in various work environments.

What Is a Weld Blanket?

A weld blanket is a protective covering made from heat-resistant materials that shield surrounding areas from welding hazards. When you're welding, sparks can travel several feet and potentially ignite flammable materials or damage surfaces. Weld blankets create a barrier that contains these risks.

Key Materials Used in Weld Blankets

Understanding materials helps you choose the right weld blanket for your needs:

- Fiberglass:The most common material, resistant to temperatures up to 1000°F (538°C)

- Silica:Handles extreme heat up to 1800°F (982°C), ideal for high-temperature welding

- Ceramic fiber:For specialized applications with temperatures exceeding 2000°F (1093°C)

- Vermiculite-coated:Provides additional protection against molten metal splash

When Should You Use a Weld Blanket?

Consider using a weld blanket in these situations:

- Welding near flammable materials like wood or insulation

- Working in confined spaces where sparks could damage nearby equipment

- Performing overhead welding where slag might fall

- Protecting finished surfaces from heat discoloration

- Creating temporary welding curtains in shared workspaces

Choosing the Right Weld Blanket

Follow these steps to select the best weld blanket for your application:

- Determine the maximum temperature your blanket needs to withstand

- Measure the area you need to protect

- Consider the welding process (MIG, TIG, stick welding produce different spark patterns)

- Evaluate portability needs (some blankets have grommets for hanging)

- Check for certifications if working in regulated industries

Proper Installation and Use

To get maximum protection from your weld blanket:

- Cover at least 3 feet beyond your immediate work area

- Secure edges with weights or clamps to prevent movement

- Overlap multiple blankets by at least 6 inches when covering large areas

- Inspect for damage before each use (look for holes or thinning areas)

- Keep the blanket flat against surfaces for best protection

Maintenance and Care

Extend your weld blanket's lifespan with proper care:

- Shake off slag and debris after each use

- Store folded or rolled in a dry location

- Clean with compressed air or a soft brush - avoid water that can degrade fibers

- Replace when you notice significant wear or reduced flexibility

- Never use damaged blankets - small holes can allow sparks through

Safety Benefits Beyond Spark Protection

Weld blankets offer additional advantages:

- Reduce UV radiation exposure from arc welding

- Contain small fires caused by sparks

- Prevent accidental burns from hot surfaces

- Minimize cleanup time by containing debris

- Protect against electrical hazards when working near live components

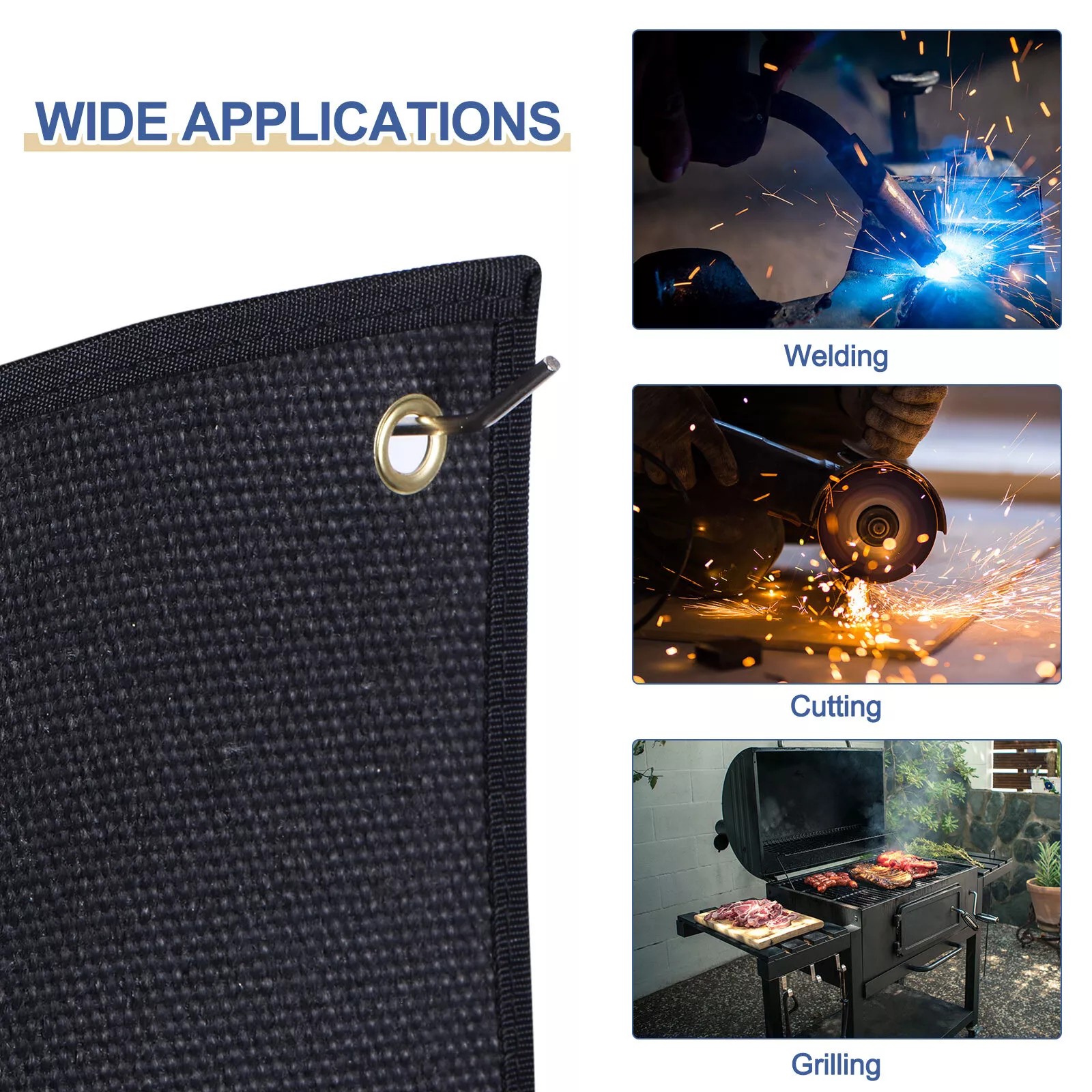

Alternative Uses for Weld Blankets

These versatile tools have applications beyond welding:

- Grinding operations that produce sparks

- Foundry work and metal pouring

- Fireproofing during hot work permits

- Protective barriers during torch cutting

- Insulation for high-temperature equipment

Conclusion

A quality weld blanket is an essential safety tool for any welding operation. By understanding materials, proper selection, and correct usage, you can significantly reduce fire risks and protect valuable equipment. Remember that no single blanket suits all situations - assess your specific needs to choose the best protection for your work environment.