WSM Welding Blanket Guide: Protection, Uses & Safety Tips for Welders

Summary:WSM welding blankets protect against sparks, heat and molten metal. This guide explains their materials, proper use cases, safety benefits, and maintenance tips for optimal protection in welding environments.

What Is a WSM Welding Blanket?

A WSM welding blanket is a heat-resistant protective barrier made from fiberglass or silica fabric. These blankets withstand temperatures up to 2000°F (1093°C), creating a safe workspace by containing sparks and preventing fire hazards. Unlike regular tarps, WSM blankets won't melt when exposed to welding splatter.

Key Features of Quality WSM Welding Blankets

When choosing a WSM welding blanket, look for these essential characteristics:

- High-temperature resistance:Minimum 1000°F continuous exposure rating

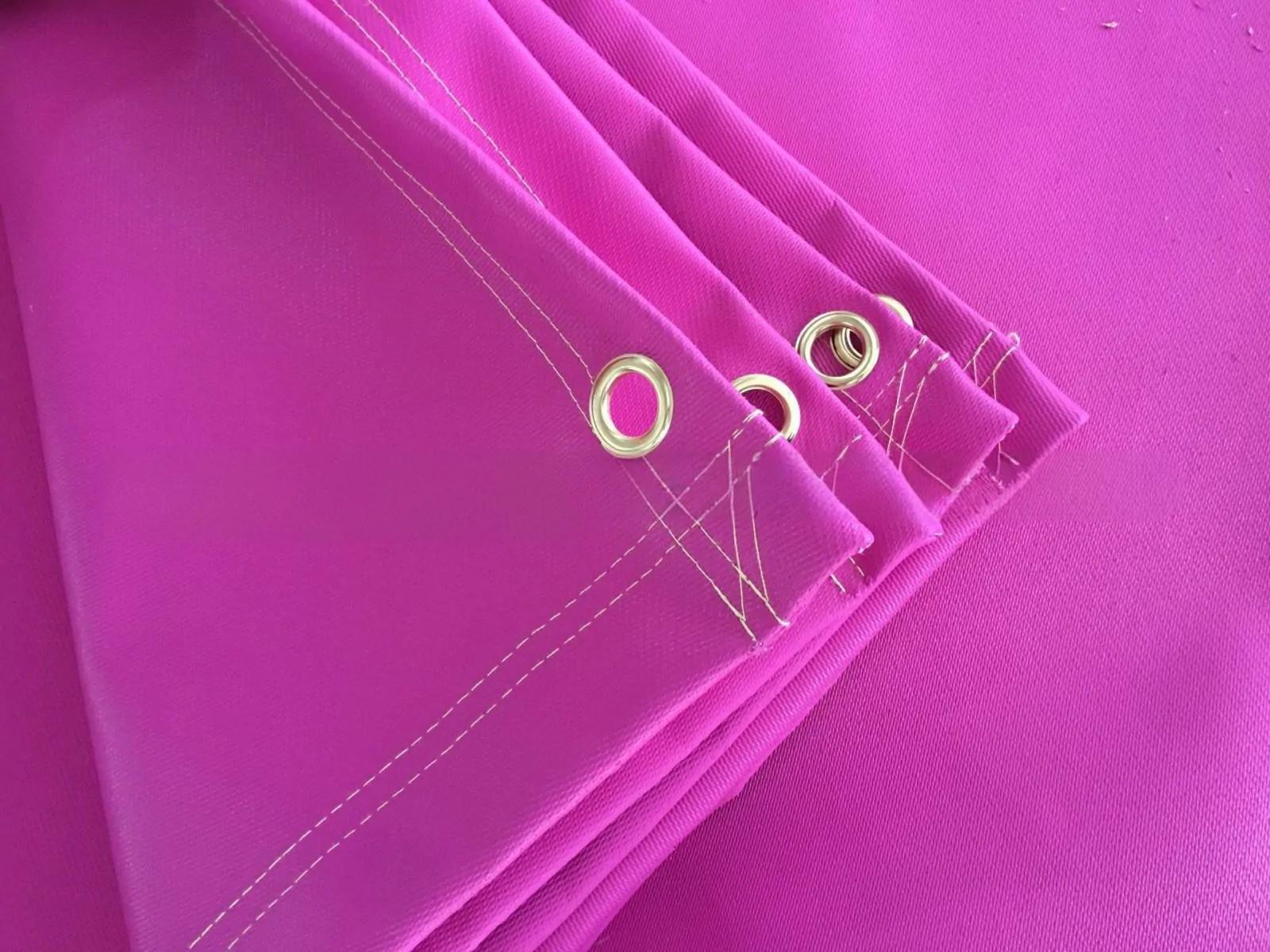

- Durable construction:Reinforced edges with grommets for secure hanging

- Flexibility:Maintains protection when draped over uneven surfaces

- Chemical resistance:Won't degrade from oils or solvents

- Visibility:Bright colors (usually silver) for easy identification

Practical Applications for WSM Welding Blankets

You'll find WSM welding blankets useful in these common scenarios:

- Workshop protection:Cover floors, walls, and equipment near welding stations

- Vehicle maintenance:Protect car interiors during exhaust work

- Construction sites:Create safe zones for hot work in confined spaces

- Emergency containment:Quickly smother small welding fires

- Multi-process shielding:Use with grinding, cutting, or brazing operations

Safety Benefits You Can't Ignore

WSM welding blankets provide three critical safety functions:

First, they prevent fire by stopping sparks from reaching flammable materials. Second, they protect bystanders from UV radiation produced during welding. Third, they contain molten metal splatter that could cause severe burns.

OSHA regulations recommend using welding blankets whenever hot work occurs near combustible materials. The WSM brand meets ANSI and NFPA standards for personal protective equipment.

Proper Maintenance for Longevity

Follow these care tips to extend your WSM welding blanket's lifespan:

- Shake off debris after each use

- Hand wash with mild detergent when heavily soiled

- Inspect for tears or thin spots monthly

- Store flat or rolled in a dry location

- Replace when fibers become brittle or discolored

Avoid folding along the same lines repeatedly, as this weakens the material. Never use damaged blankets - small holes can allow sparks to pass through.

Choosing the Right Size and Weight

WSM offers welding blankets in various sizes from 3'x3' to 12'x12'. Consider these factors when selecting:

| Workspace Size | Recommended Blanket |

|---|---|

| Small bench area | 4'x4' or 4'x6' |

| Medium shop floor | 6'x6' or 6'x8' |

| Large industrial area | 8'x8' or larger |

Heavier blankets (18oz+) offer better protection for prolonged welding, while lighter versions (12oz) work well for occasional use.

Alternative Uses Beyond Welding

Your WSM welding blanket serves multiple purposes:

- Fireplace or forge lining

- Kiln insulation during pottery work

- Grill heat shield for outdoor cooking

- Emergency roof patch for chimney repairs

Remember that non-welding uses may void manufacturer warranties. Always check temperature ratings for alternative applications.

Final Safety Reminders

While WSM welding blankets significantly reduce hazards, they don't eliminate all risks. Always wear proper PPE including gloves, helmets, and flame-resistant clothing. Maintain at least 15 feet between welding operations and combustible materials, even when using blankets. Never leave hot blankets unattended until completely cooled.

By selecting the appropriate WSM welding blanket and using it correctly, you create a safer environment for yourself and coworkers while complying with industry safety standards.