Small Welding Blanket: Essential Protection for Precision Welding Jobs

Summary:A small welding blanket protects surfaces from sparks and heat during welding. This guide explains its benefits, materials, proper usage, and how to choose the right one for your projects.

Why You Need a Small Welding Blanket

When working on small welding projects, a small welding blanket becomes your best safety partner. Unlike large industrial blankets, these compact versions offer precise protection exactly where you need it. They prevent sparks, slag, and heat from damaging surrounding surfaces while being easy to maneuver in tight spaces.

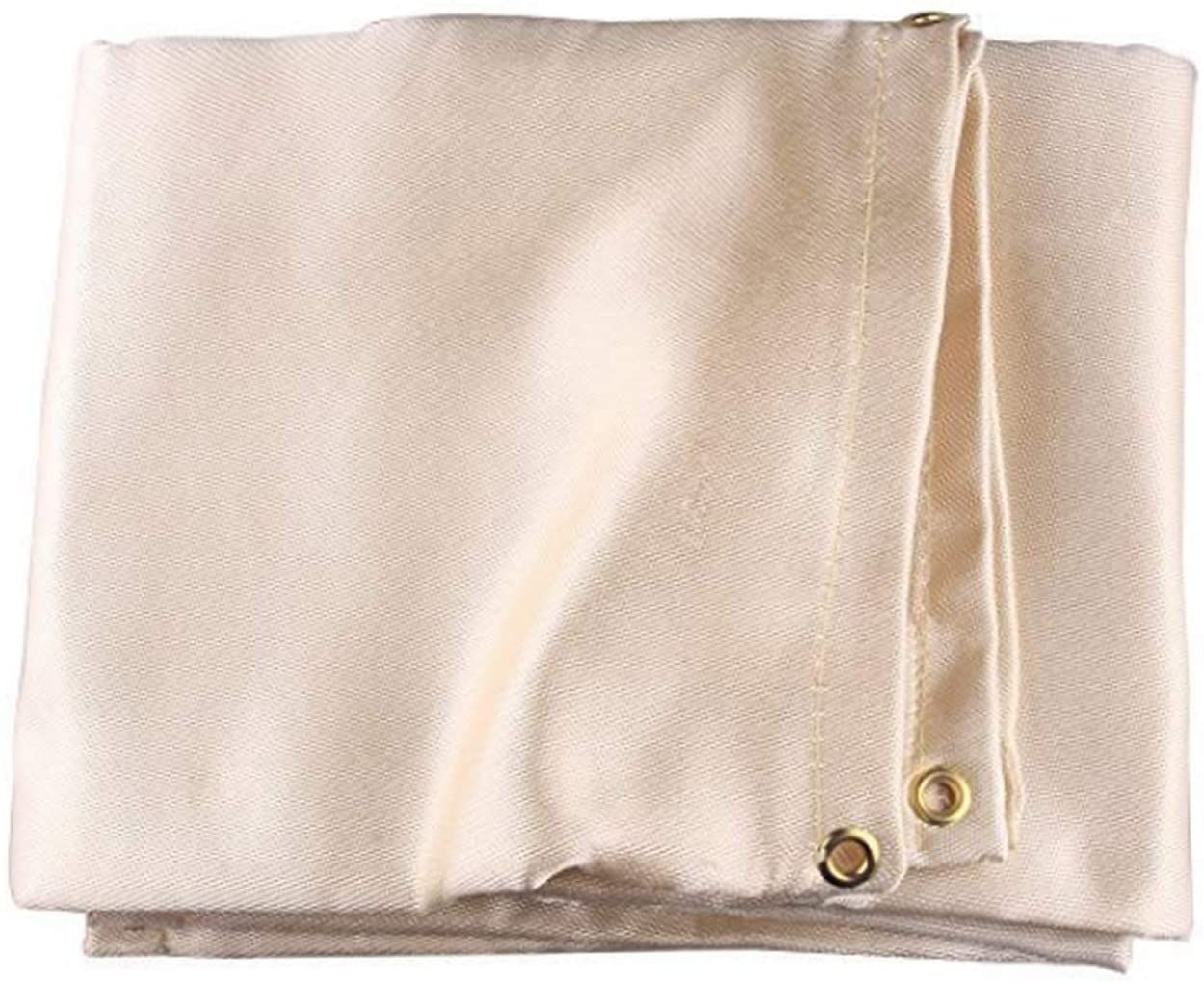

Key Features of Quality Small Welding Blankets

The best small welding blankets share these characteristics:

- Heat resistance:Withstands temperatures up to 2000°F (1093°C)

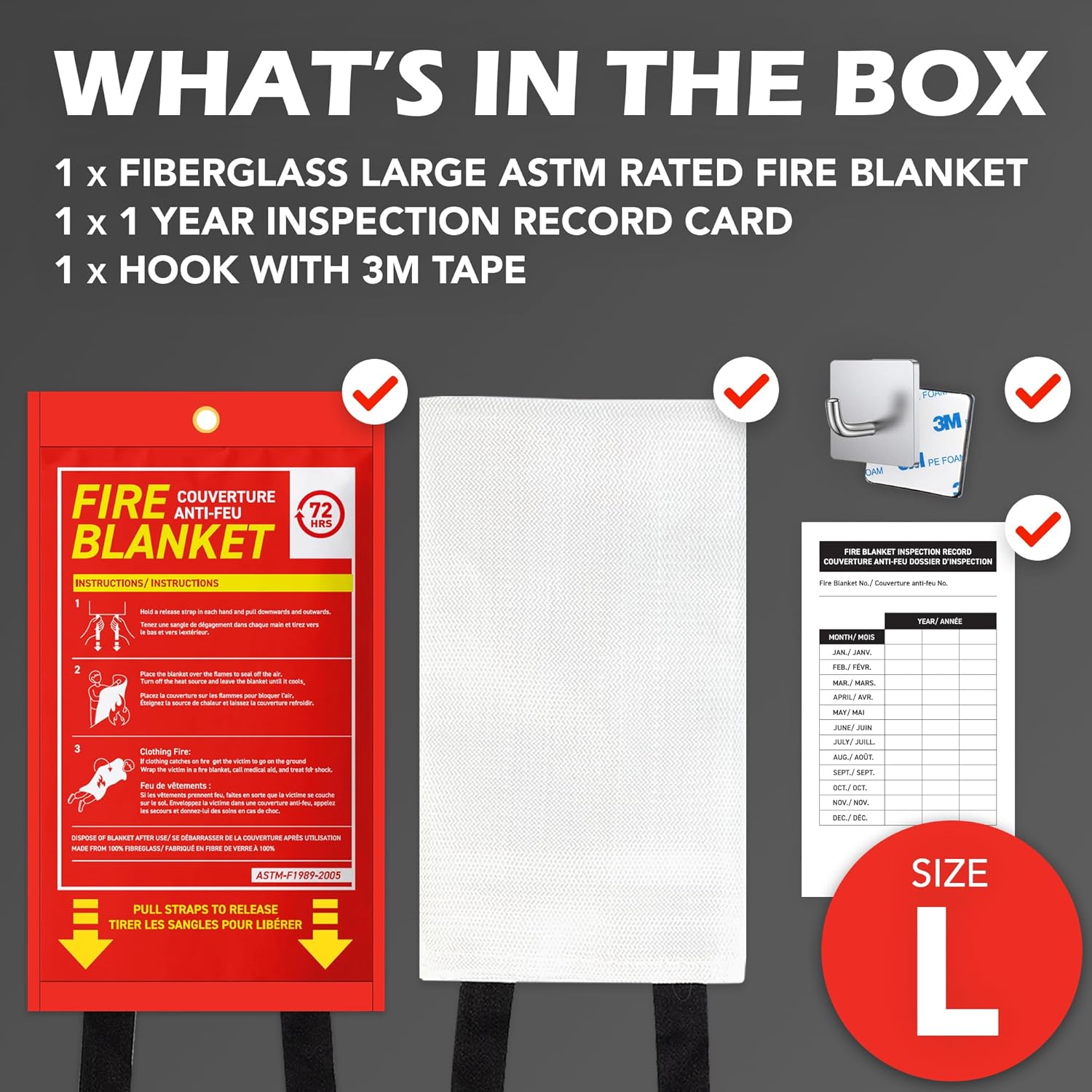

- Flexible material:Typically fiberglass or silica fabric that drapes easily

- Compact size:Usually 3'x3' to 4'x6' for focused protection

- Durable construction:Reinforced edges prevent fraying

Choosing the Right Small Welding Blanket

Consider these factors when selecting your small welding blanket:

- Project type:MIG welding requires different protection than TIG or stick welding

- Work area size:Measure your typical workspace to determine ideal blanket dimensions

- Material thickness:Thicker blankets (1/8"+) offer better protection for high-heat applications

- Portability needs:Some small welding blankets fold compactly for easy transport

Proper Use and Maintenance

To get the most from your small welding blanket:

- Always position it between your work and vulnerable surfaces

- Overlap multiple blankets for larger coverage areas

- Inspect regularly for holes or thin spots

- Clean with compressed air - never wash fiberglass blankets

- Store flat or rolled to prevent permanent creases

Safety Advantages Over Alternatives

A small welding blanket outperforms makeshift solutions because:

- It won't catch fire like cardboard or cloth

- Provides consistent protection unlike metal sheets that conduct heat

- Absorbs sparks better than plastic sheeting that can melt

- Flexes to cover irregular surfaces unlike rigid barriers

Common Applications

Small welding blankets excel in these situations:

- Auto repair in cramped garages

- Precision metal fabrication

- HVAC duct work

- Home DIY projects

- Mobile welding services

- Art metalwork

Cost vs. Benefit Analysis

While a quality small welding blanket costs $30-$100, it prevents:

- Expensive surface repairs from burn marks

- Fire damage to your workspace

- Time wasted setting up temporary protection

- Potential injury from ricocheting sparks

Expert Tips for Maximum Protection

Professional welders recommend:

- Use binder clips to secure blankets in place

- Layer two blankets for extra protection on critical jobs

- Mark "hot zones" with chalk where blankets receive most sparks

- Rotate blanket position periodically to distribute wear

- Keep a spare small welding blanket for when one needs cleaning

Investing in a proper small welding blanket saves money, time, and frustration while making your welding projects safer and more professional. Choose quality materials suited to your specific needs, and maintain your blanket properly for years of reliable service.