REC TEC Mini Welding Blanket: Essential Protection for Small Jobs

Summary:The REC TEC Mini Welding Blanket provides compact, heat-resistant protection for welding projects. This guide covers its features, proper use cases, safety benefits, and maintenance tips for optimal performance.

Why You Need the REC TEC Mini Welding Blanket

When working with sparks, molten metal, or intense heat, protection matters. The REC TEC Mini Welding Blanket gives you a portable safety solution for smaller welding jobs. Unlike bulky full-size blankets, this compact version fits easily in your toolbox while offering the same flame-resistant protection.

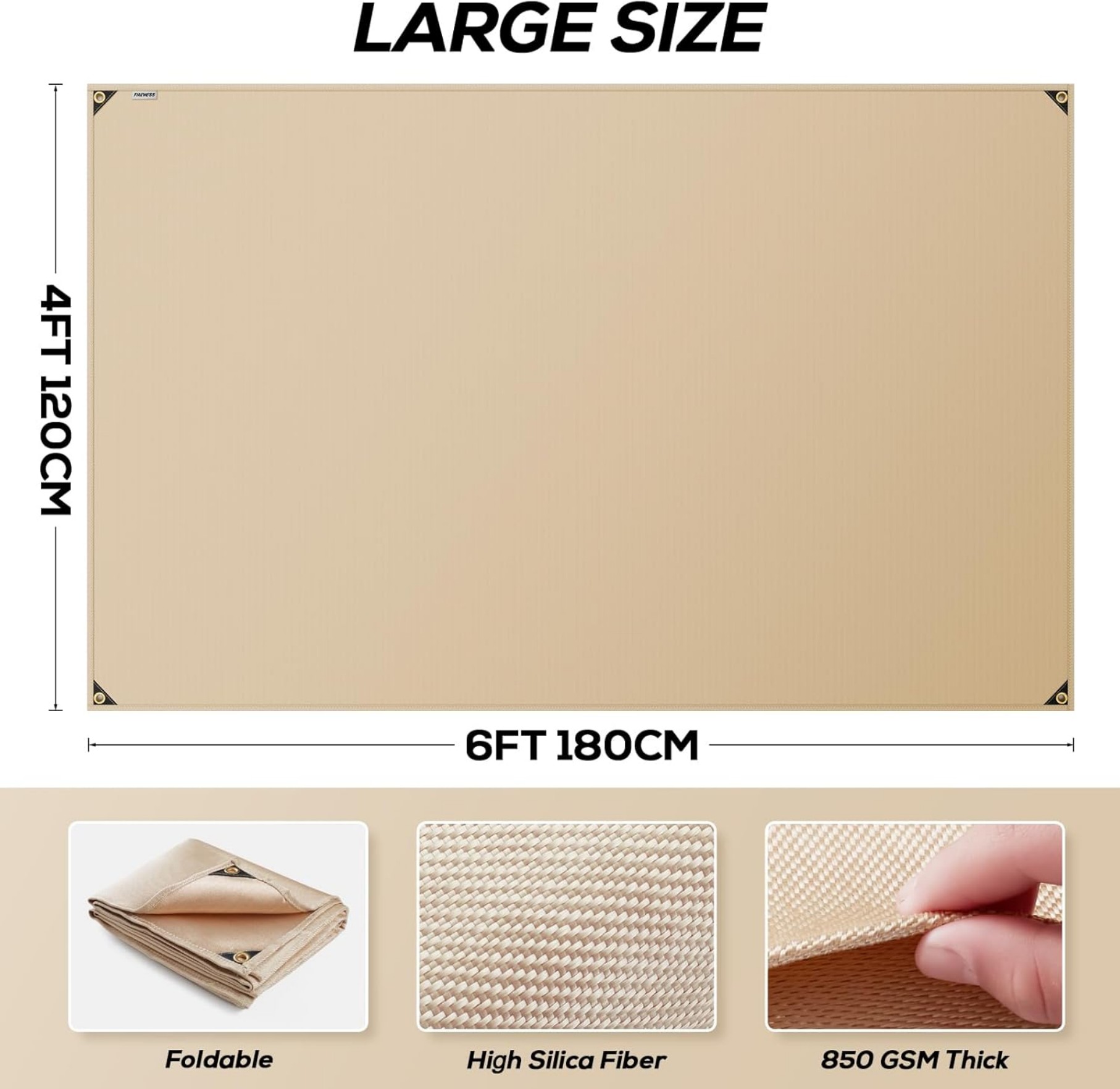

Made from fiberglass with a silicone coating, it withstands temperatures up to 1,800°F (982°C). The mini size (typically 2' x 3') makes it perfect for:

- Spot welding repairs

- Small fabrication projects

- Mobile welding services

- Protecting workbenches

- Covering nearby flammable materials

Key Features That Set It Apart

The REC TEC Mini Welding Blanket includes several professional-grade features:

1. Superior Heat Resistance

With its multi-layer fiberglass construction, the blanket doesn't just resist heat - it won't melt or drip when exposed to welding sparks. The silicone coating adds extra protection against molten metal splatter.

2. Lightweight Yet Durable

Weighing just 1-2 pounds, it's easy to carry to different job sites. Despite being lightweight, the tightly woven fibers prevent tears from typical welding debris.

3. Flexible Protection

Unlike rigid shields, the blanket conforms to irregular shapes. Drape it over pipes, machinery parts, or work surfaces that need temporary protection.

Proper Usage Tips

To get the most from your REC TEC Mini Welding Blanket:

- Inspect before each use:Check for holes or thin spots that compromise protection

- Secure properly:Use welding magnets or clips to prevent shifting during work

- Overlap coverage:For larger areas, overlap multiple blankets by at least 6 inches

- Keep it clean:Brush off debris after use to maintain heat resistance

- Store correctly:Fold neatly and keep in a dry place away from chemicals

Safety Advantages Over Alternatives

While some welders use makeshift protections like wet rags or metal sheets, the REC TEC Mini Welding Blanket offers distinct safety benefits:

| Protection Method | Drawbacks | REC TEC Blanket Solution |

|---|---|---|

| Wet rags/cloth | Can dry out and catch fire | Non-combustible material |

| Metal sheets | Conduct heat to other surfaces | Insulates against heat transfer |

| Ceramic tiles | Fragile and heavy | Flexible and lightweight |

Maintenance for Longevity

With proper care, your REC TEC Mini Welding Blanket can last for years:

- Cleaning:Shake out debris after each use. For stubborn residue, use a soft brush - never wash with water as it degrades the silicone coating.

- Storage:Hang or fold neatly in a dry area. Avoid compressing under heavy objects that could damage the fibers.

- Inspection:Regularly check for thinning areas, especially along fold lines. Replace if you see significant wear.

When to Upgrade to a Larger Size

While the mini blanket excels for small jobs, consider a full-size welding blanket if you regularly work on:

- Projects larger than 3' x 4'

- High-splatter processes like arc gouging

- Areas with multiple ignition hazards

The REC TEC Mini Welding Blanket delivers professional protection in a convenient size. Its combination of portability and high-temperature resistance makes it an essential tool for welders who value both safety and efficiency in their workspace.