Weld Blankets: Essential Protection for Welding Safety and Workplace Efficiency

Summary:Weld blankets are heat-resistant protective covers that shield workers and surfaces from welding hazards. This guide explains their materials, types, proper usage, and how they enhance safety while saving costs in industrial and DIY welding applications.

What Are Weld Blankets and Why Do You Need Them?

Weld blankets are specialized protective covers designed to withstand extreme heat from welding operations. When you're working with molten metal, sparks, and intense heat, these blankets create a crucial barrier between your welding area and surrounding people, equipment, or flammable materials.

Unlike regular tarps that would melt instantly, weld blankets are made from heat-resistant materials like fiberglass, silica, or ceramic fabrics. They typically come in thicknesses ranging from 1/16" to 1/4" and can handle temperatures from 500°F to 3000°F depending on the material grade.

Key Benefits of Using Weld Blankets

1. Spark and Splatter Protection:Weld blankets catch hot metal particles that fly during welding, preventing burns and fire hazards. A single spark can ignite flammable materials, making this protection essential.

2. Heat Shielding:They reduce radiant heat transfer to nearby surfaces, protecting sensitive equipment, electrical wiring, and preventing heat damage to workbenches or floors.

3. Work Area Containment:By draping weld blankets around your work area, you create a controlled zone that keeps hazards contained while allowing necessary ventilation.

4. Cost Savings:Preventing just one fire or equipment damage incident can save thousands in repair costs and downtime.

Types of Weld Blankets and Their Applications

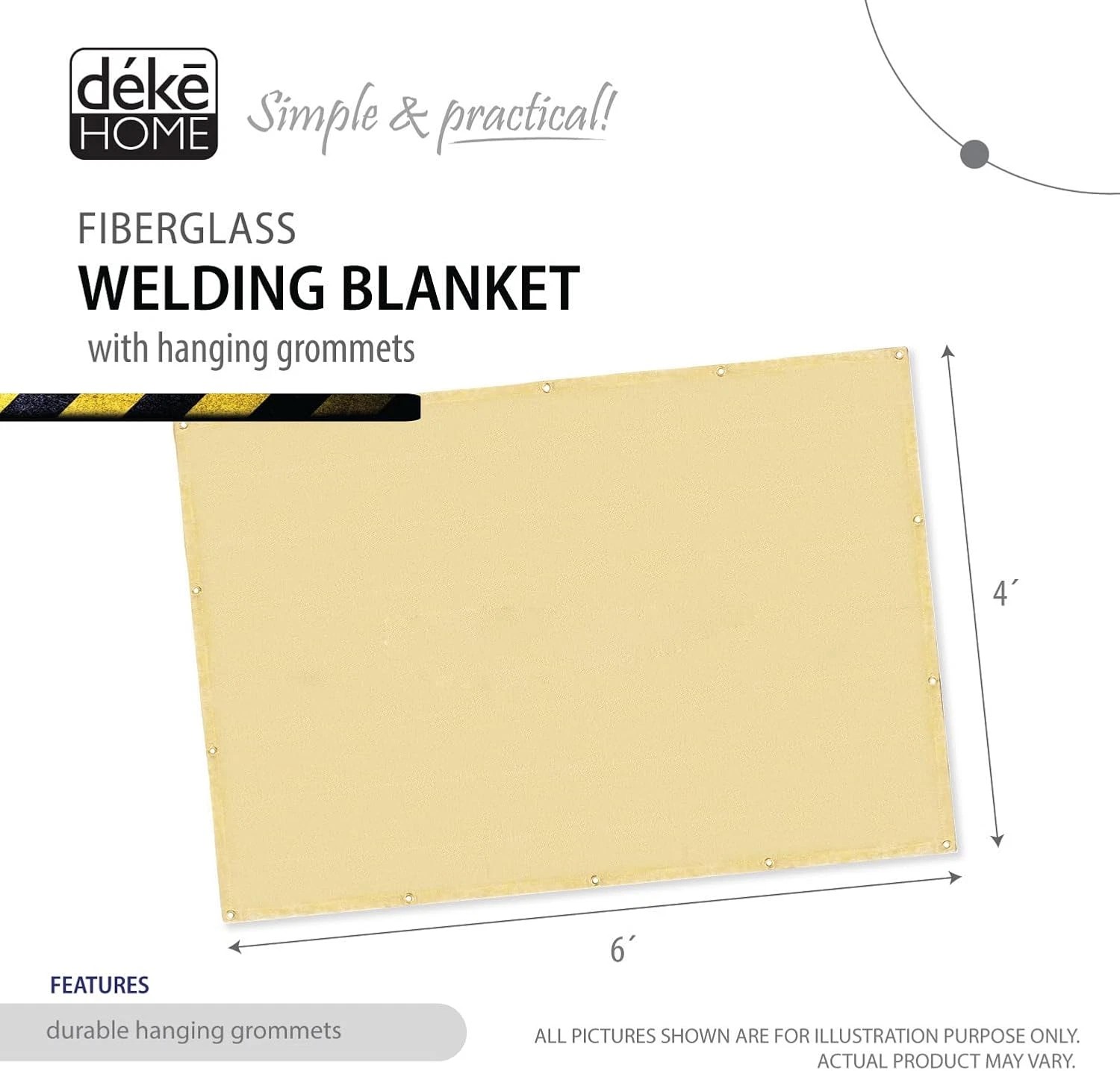

Fiberglass Weld Blankets

The most common type, suitable for temperatures up to 1000°F. These flexible blankets work well for general welding, grinding, and heat-treating applications. Look for silicone-coated versions for added durability.

Silica Weld Blankets

Withstand temperatures up to 1800°F, ideal for high-heat applications like plasma cutting or heavy welding. These are more rigid but offer superior protection.

Ceramic Weld Blankets

The premium option for extreme temperatures (up to 3000°F), used in foundries or for specialized welding processes. These provide the highest level of protection but come at a higher cost.

How to Choose the Right Weld Blanket

Consider these factors when selecting weld blankets:

- Temperature rating:Match it to your welding process's maximum heat output

- Size:Measure your work area and add extra coverage

- Material weight:Heavier blankets last longer but are less flexible

- Edge treatment:Look for reinforced edges with grommets for hanging

- Compliance:Ensure the blanket meets relevant safety standards

Proper Usage and Maintenance Tips

To get the most from your weld blankets:

- Inspect blankets before each use for tears or thin spots

- Overlap multiple blankets by at least 6 inches when covering large areas

- Secure blankets properly using hooks, clamps, or weights

- Keep blankets clean - brush off metal particles after use

- Store folded or rolled in a dry area when not in use

- Replace blankets when they show significant wear or damage

Beyond Welding: Other Uses for Weld Blankets

While designed for welding, these versatile blankets serve multiple purposes:

- Protective covers for hot work permits

- Fireproof barriers during demolition

- Heat shields for automotive repairs

- Protection during metal grinding operations

- Temporary furnace or boiler insulation

Safety First: What Weld Blankets Don't Do

While weld blankets provide excellent protection, remember they don't replace:

- Proper personal protective equipment (PPE) like welding helmets and gloves

- Adequate ventilation systems

- Fire extinguishers and other emergency equipment

- Proper training in welding safety procedures

Always combine weld blankets with other safety measures for comprehensive protection.

Investing in Quality Weld Blankets Pays Off

While you might find cheaper alternatives, quality weld blankets from reputable manufacturers offer better protection and last longer. Consider them an essential part of your welding safety equipment rather than an optional accessory. The small upfront cost is insignificant compared to the potential savings from prevented accidents and equipment damage.

Whether you're a professional welder or a DIY enthusiast, proper use of weld blankets significantly reduces risks while improving work efficiency. Choose the right type for your needs, use them correctly, and maintain them well to ensure long-lasting protection for all your welding projects.