Fiberglass Cloth vs Welding Blanket: Key Differences for Heat Protection

Summary:Fiberglass cloth and welding blankets both provide heat resistance, but differ in thickness, flexibility, and specific applications. This guide explains their properties to help you choose the right material for your project.

Understanding Fiberglass Cloth

Fiberglass cloth is a woven material made from fine glass fibers. You'll find it in various weights and weaves, typically ranging from 6 to 10 ounces per square yard. The fabric remains flexible while offering excellent heat resistance up to 1000°F (538°C).

Common uses include:

- Heat shields in automotive applications

- Insulation wraps for pipes and ductwork

- Protective covers for sensitive equipment

Unlike welding blankets, fiberglass cloth allows for more precise cutting and shaping. You can easily sew or bond it to create custom-fit protective solutions.

Welding Blanket Characteristics

Welding blankets are thicker, heavier materials designed specifically for welding applications. These typically consist of multiple layers of fiberglass or silica fabric, with some models incorporating additional protective coatings.

Key features include:

- Higher temperature resistance (up to 2000°F/1093°C for premium models)

- Greater spark and slag protection

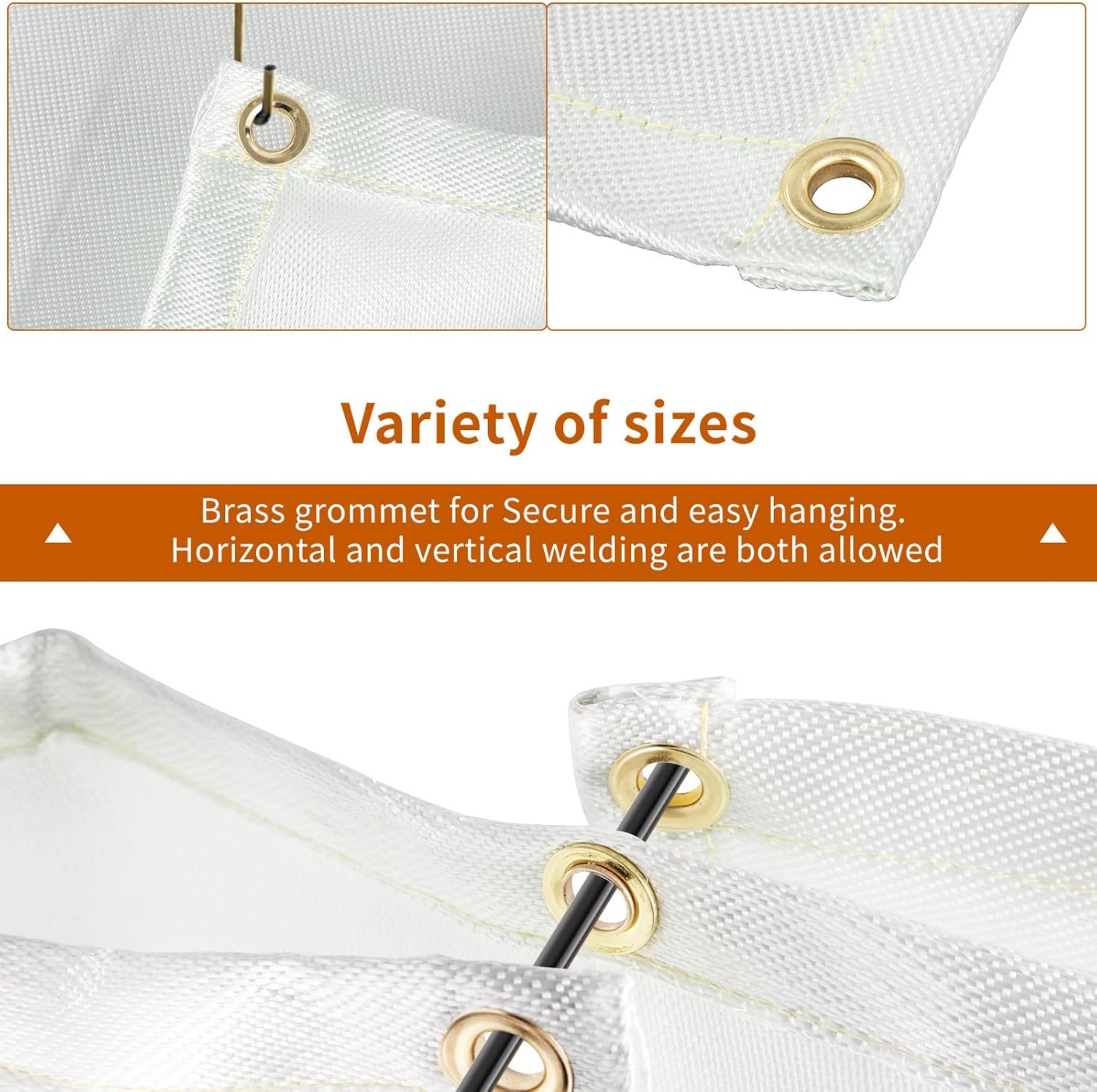

- Reinforced edges for durability

You'll appreciate welding blankets when working with open flames or intense heat sources that could damage ordinary fiberglass cloth.

Direct Comparison: Fiberglass Cloth vs Welding Blanket

| Feature | Fiberglass Cloth | Welding Blanket |

|---|---|---|

| Thickness | 0.5-2 mm | 3-10 mm |

| Temperature Resistance | Up to 1000°F | Up to 2000°F |

| Flexibility | High | Moderate to Low |

| Primary Use | General heat protection | Welding and extreme heat |

Choosing Between Fiberglass Cloth and Welding Blankets

Select fiberglass cloth when you need:

- Lightweight protection for moderate temperatures

- Custom-shaped covers or wraps

- Breathable heat barriers

Choose welding blankets when you require:

- Protection from welding sparks and molten metal

- Barriers against direct flame contact

- Heavy-duty, ready-to-use protection

Safety Considerations

Both materials require proper handling:

- Always wear gloves when handling fiberglass materials

- Inspect for damage before each use

- Keep away from open edges that could unravel

- Store in dry conditions to prevent moisture damage

Remember that while these materials resist heat, they can still transfer warmth. Always use additional insulation when necessary.

Maintenance and Care

Proper care extends the life of both fiberglass cloth and welding blankets:

- Shake out debris after use

- Spot clean with mild detergent when needed

- Air dry completely before storage

- Fold rather than crease to prevent fiber damage

Replace any material showing significant wear, fraying, or heat damage.

Professional Applications

In industrial settings, the choice between fiberglass cloth and welding blankets often depends on specific job requirements:

Automotive shopstypically use fiberglass cloth for exhaust wraps and welding blankets for work area protection. Construction sitesfavor welding blankets for hot work permits, while manufacturing plantsmight use both for different processes.

Understanding these differences helps you select the most appropriate and cost-effective solution for your thermal protection needs.