Welding Blanket for Floor: Fireproof Protection Guide

This guide explains how welding blankets for floors protect surfaces from sparks, heat, and molten metal. You'll learn about materials, safety standards, proper usage, and maintenance to maximize protection during welding projects.

What Is a Welding Blanket for Floor?

A welding blanket for floor is a fire-resistant protective covering designed to shield surfaces from welding hazards. When you're working with hot metal, sparks can travel several feet and damage floors. These blankets create a barrier that prevents costly damage to concrete, wood, or other flooring materials.

Key Features of Quality Floor Welding Blankets

When choosing a welding blanket for floor protection, look for these essential characteristics:

- Heat resistance:Rated for at least 1,000°F (538°C) to withstand welding temperatures

- Material durability:Fiberglass or silica fabric with reinforced edges

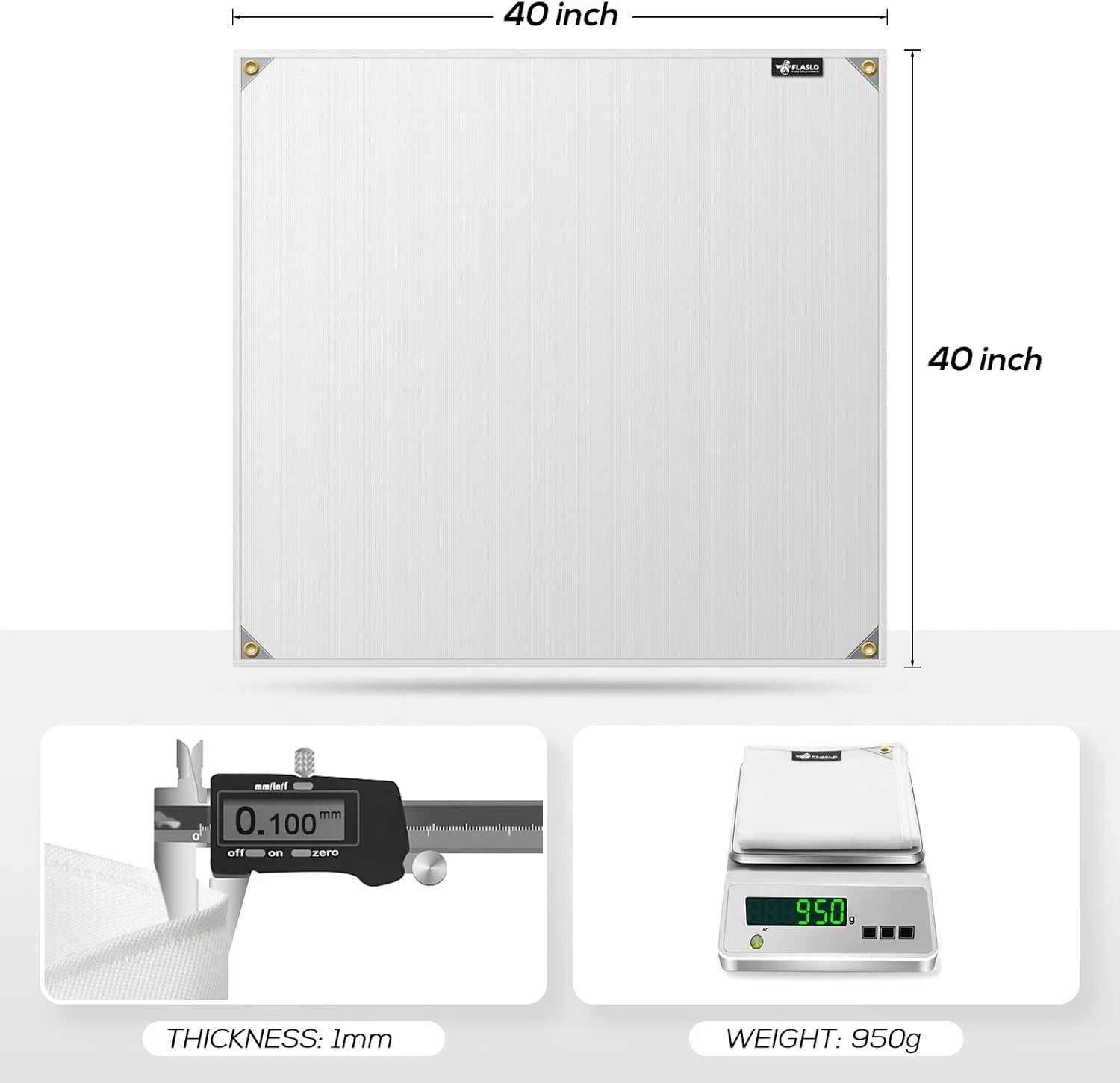

- Size options:Typically 3'x3' to 10'x10' for floor coverage

- Non-conductive:Important for electrical safety in welding environments

- Chemical resistance:Protects against oils and solvents common in workshops

How to Properly Use Your Welding Blanket

To get maximum protection from your welding blanket for floor:

- Clear the work area of flammable materials before laying down the blanket

- Ensure complete coverage of the floor area where sparks might land

- Overlap multiple blankets if needed for larger projects

- Secure edges with weights or non-flammable tape to prevent shifting

- Inspect for damage before each use - replace if there are holes or fraying

Maintenance Tips for Long-Lasting Protection

Your welding blanket for floor will last longer with proper care:

- Shake off debris after each use - never wash with water

- Store flat or rolled (never folded) to prevent material fatigue

- Keep away from sharp objects that could puncture the material

- Replace immediately if the blanket becomes stiff or brittle

- Check manufacturer guidelines for specific care instructions

Safety Standards for Welding Blankets

Reputable welding blankets for floors meet these safety certifications:

- NFPA 701 (fire resistance standard)

- OSHA 1910.252 (welding safety requirements)

- ASTM F1959 (arc rating for protective equipment)

Always verify these certifications before purchasing. Professional-grade blankets will display compliance markings.

Choosing Between Different Types

Welding blankets for floors come in three main varieties:

- Fiberglass:Most common, affordable option with good heat resistance

- Silica:Higher temperature rating (up to 2,000°F) for heavy-duty work

- Ceramic:Extreme heat protection for specialized applications

For most floor protection needs, fiberglass blankets provide sufficient protection at the best value.

Common Mistakes to Avoid

When using a welding blanket for floor protection, steer clear of these errors:

- Using damaged blankets with holes or thin spots

- Placing the blanket too close to the actual weld point

- Assuming one blanket size fits all projects

- Ignoring manufacturer's temperature ratings

- Storing near chemicals that could degrade the material

When to Replace Your Welding Blanket

Monitor your welding blanket for floor protection regularly. Replace it when you notice:

- Visible burns or charring covering more than 10% of the surface

- Stiffness that prevents the blanket from lying flat

- Frayed edges that could unravel further

- Discoloration indicating material breakdown

- Any holes larger than 1/4 inch in diameter

Investing in a quality welding blanket for floor protection saves you from costly floor repairs and improves workshop safety. Choose the right material and size for your projects, use it properly, and maintain it well for reliable, long-term protection.