DIY Body Armor Welding Blanket: How to Make Your Own Protective Gear

This guide explains how to create a DIY body armor welding blanket for heat and spark protection. You'll learn material selection, construction techniques, and safety considerations for making effective welding protection at home.

Why Make a DIY Welding Blanket?

A welding blanket protects you from sparks, slag, and heat during welding projects. While commercial options exist, making your own lets you customize size and materials while saving money. The "DIY body armor welding blanket" approach combines protection with flexibility.

Materials You'll Need

For your DIY body armor welding blanket, gather these materials:

- Fiberglass fabric (18 oz/sq yd minimum)

- Kevlar or carbon fiber fabric (optional for extra protection)

- High-temperature resistant thread

- Grommets and setting tool

- Heavy-duty sewing machine or leather needle

- Fire-resistant binding tape

Step-by-Step Construction

1. Measure and Cut

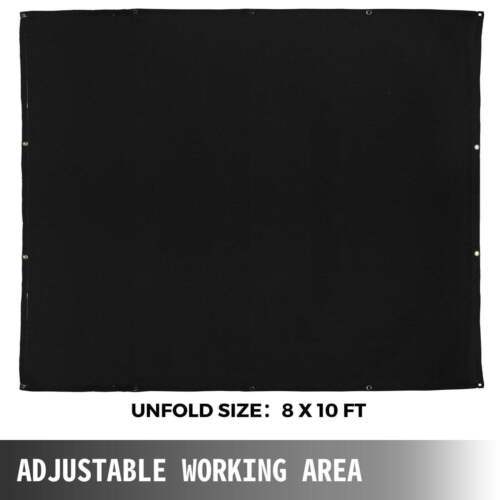

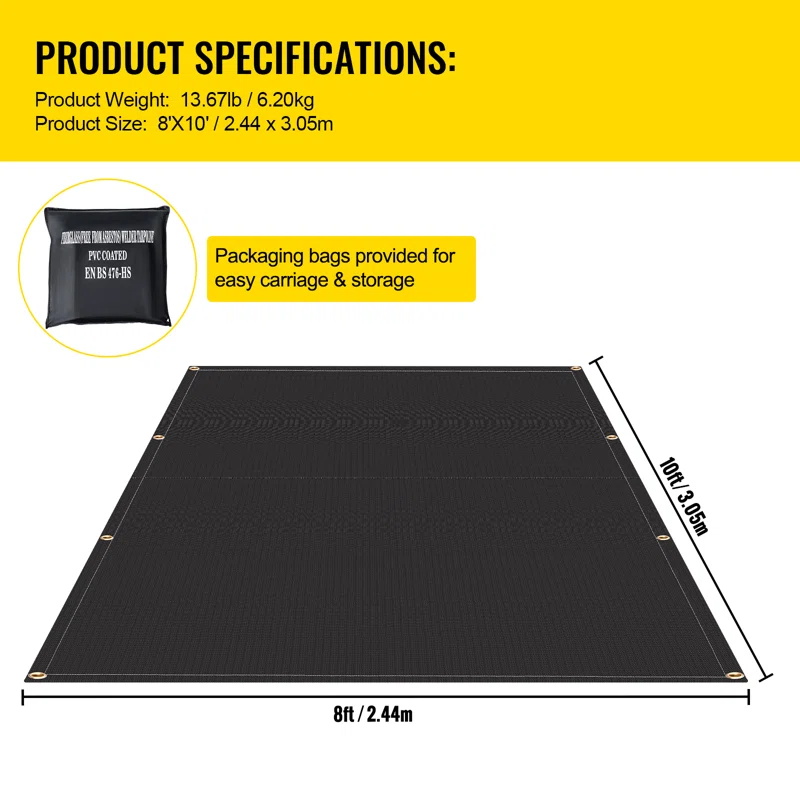

Decide your blanket size - common dimensions are 4'x6' or 6'x8'. Add 1 inch to all sides for seams. Cut your fiberglass fabric to size using sharp scissors.

2. Reinforce Edges

Fold edges over 1/2 inch twice to create a hem. Sew with high-temp thread, then add fire-resistant binding tape over the seams for extra durability.

3. Add Grommets

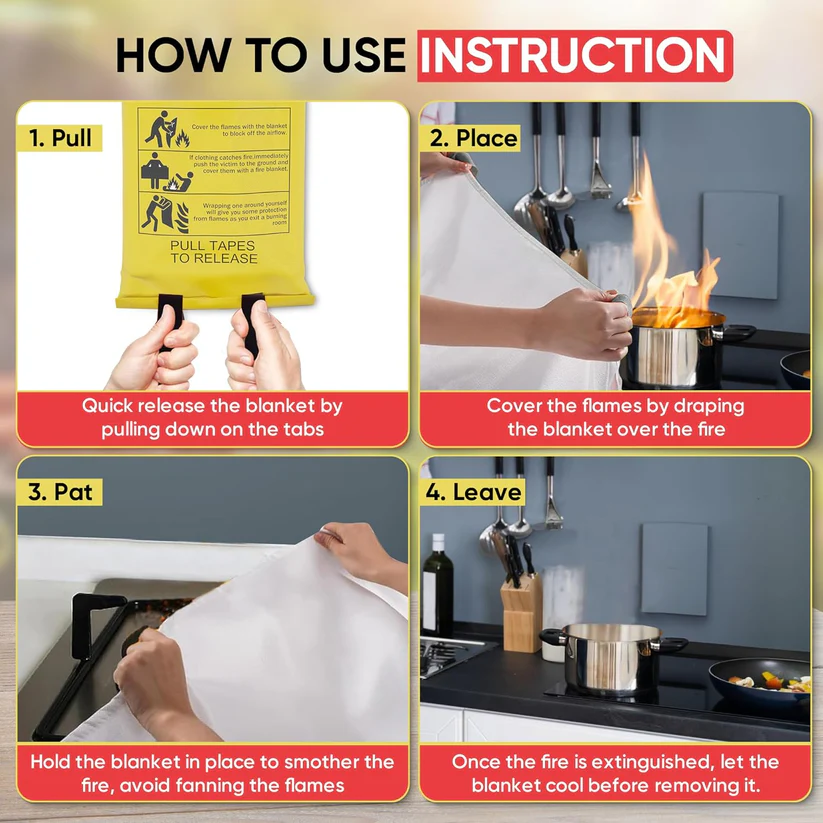

Space grommets every 12-18 inches around the perimeter. These let you hang the blanket or secure it to surfaces during work.

4. Optional Armor Layer

For a true "body armor" version, add a layer of Kevlar between two fiberglass sheets. This creates impact resistance while maintaining flexibility.

Safety Considerations

Your DIY body armor welding blanket must meet basic safety standards:

- Withstand temperatures up to 2000°F (1093°C)

- Be completely non-flammable

- Have no exposed edges that could fray

- Cover all intended work areas adequately

Maintenance Tips

To keep your welding blanket effective:

- Inspect for damage before each use

- Shake out slag and debris regularly

- Store flat or rolled, never folded

- Replace when more than 10% of surface shows wear

When to Choose DIY vs. Commercial

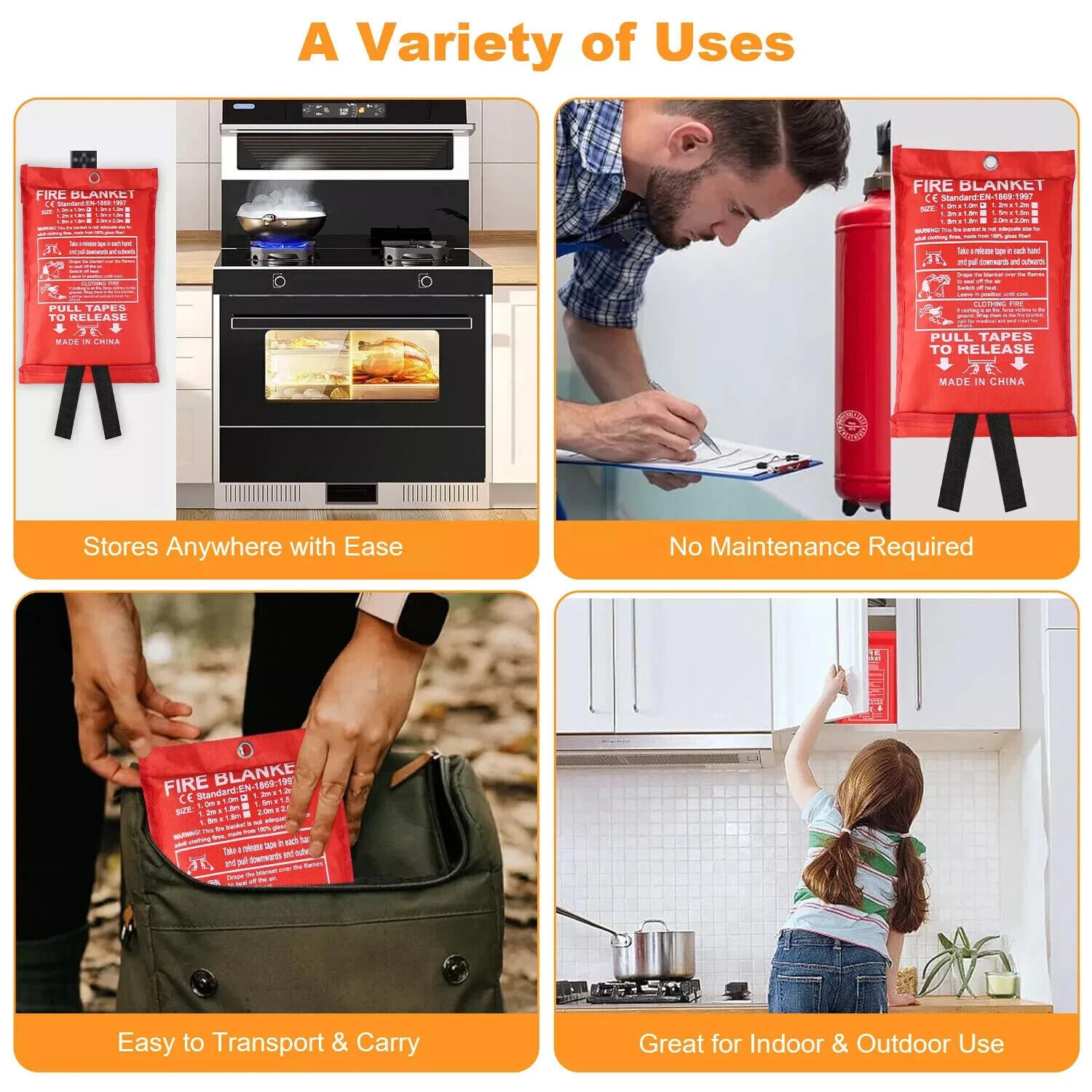

A DIY body armor welding blanket works best for:

- Custom sizes commercial options don't offer

- Projects needing specific material combinations

- Budget-conscious welders with sewing skills

Commercial blankets may be better for critical industrial applications where certified protection levels are required.

Advanced Modifications

For specialized needs, consider these upgrades to your DIY blanket:

- Add reflective aluminum coating for radiant heat protection

- Incorporate quick-release buckles for easy deployment

- Create segmented panels for better flexibility

- Include pockets for tool storage

Troubleshooting Common Issues

If your DIY body armor welding blanket has problems:

- Fraying edges:Apply more binding tape or high-temp sealant

- Stiff material:Break in by rolling and unrolling repeatedly

- Grommet failure:Replace with larger, heavy-duty grommets

Final Thoughts

Creating a DIY body armor welding blanket gives you customized protection at lower cost. While requiring some effort, the result provides satisfaction and exactly meets your needs. Always prioritize safety and replace your blanket when it shows significant wear.