Forney Welding Blanket: Essential Protection for Safe Welding Projects

The Forney welding blanket provides reliable heat and spark protection for welding, grinding, and other high-temperature applications. Made from durable materials, it shields your workspace from fire hazards while being flexible and easy to use.

Why You Need a Quality Welding Blanket

Welding creates extreme temperatures that can easily ignite nearby materials. A Forney welding blanket acts as a protective barrier between your work area and flammable surfaces. Unlike makeshift solutions, these specialized blankets:

- Withstand temperatures up to 1,800°F (depending on model)

- Resist sparks, slag, and molten metal splatter

- Provide consistent coverage without gaps

- Are reusable and easy to clean

Key Features of Forney Welding Blankets

Forney offers several welding blanket options designed for different applications:

Fiberglass Construction:The core material is woven fiberglass with special coatings that enhance durability while remaining flexible.

Size Options:Available in various dimensions (common sizes include 4'x6' and 6'x8') to match your workspace requirements.

Temperature Resistance:Different models handle varying heat levels - check specifications for your specific welding needs.

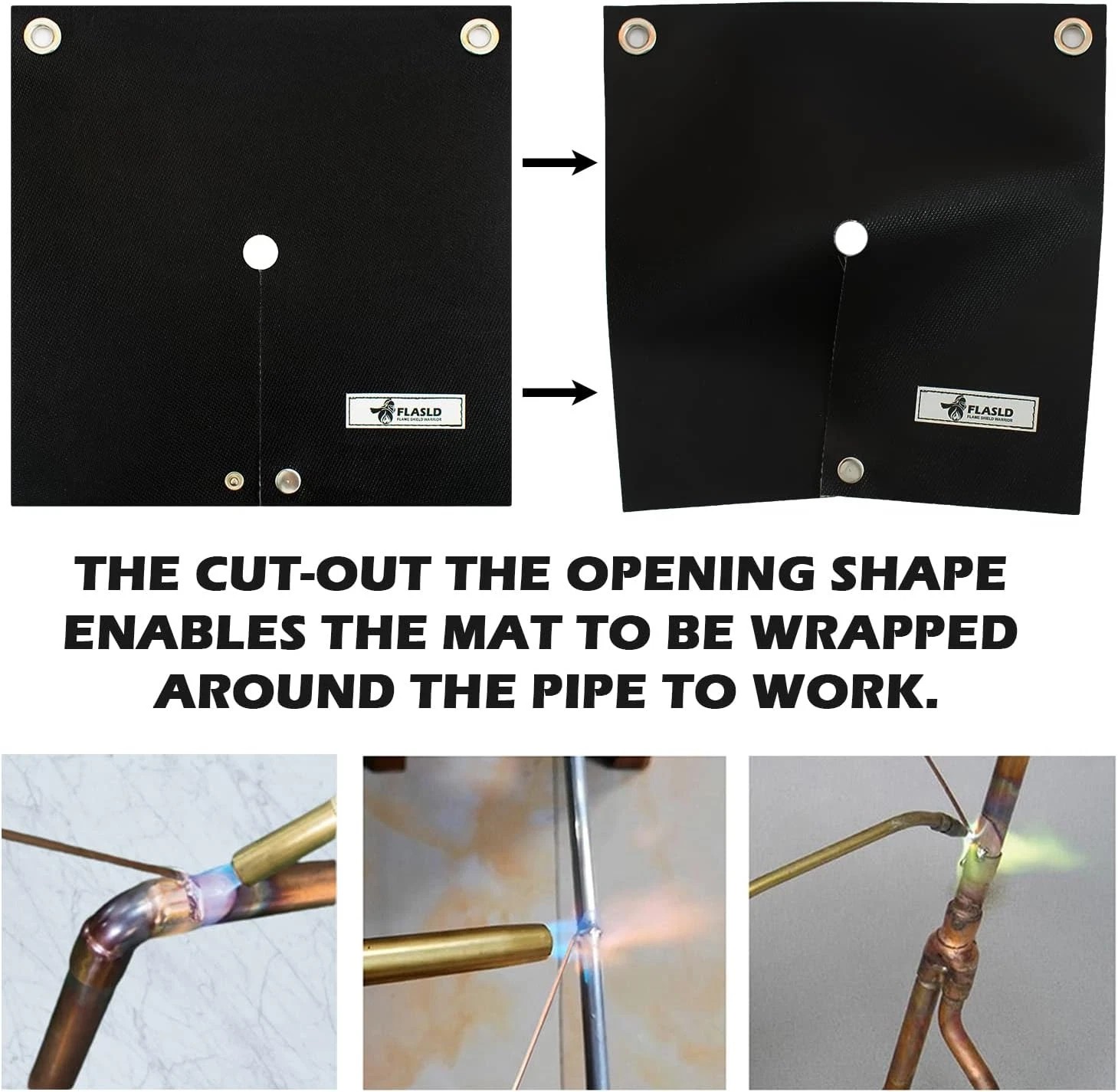

Reinforced Edges:Grommets or other edge reinforcements allow for secure placement and prevent fraying.

Proper Use of Your Forney Welding Blanket

To maximize protection and extend your blanket's lifespan:

- Cover all nearby flammable surfaces completely - don't leave gaps

- Position the blanket so sparks roll away from unprotected areas

- Secure edges with weights or fasteners to prevent shifting

- Inspect regularly for damage and replace if compromised

Maintenance and Care Tips

With proper care, your Forney welding blanket will provide years of reliable service:

- Shake off debris after each use

- Wash with water (no harsh chemicals) when heavily soiled

- Store flat or rolled - avoid sharp folds that can weaken fibers

- Keep away from oils and solvents that could degrade materials

Comparing Forney to Other Welding Blankets

Forney welding blankets stand out for their:

- Consistent quality:Uniform fiberglass weave without thin spots

- Trusted brand reputation:Forney has been manufacturing welding products since 1932

- Value pricing:Competitive costs without sacrificing protection

- Wide availability:Easy to find at welding supply stores and online

Safety Considerations

While Forney welding blankets provide excellent protection, remember:

- No blanket makes welding completely risk-free - always follow all safety protocols

- Use additional protection (fire extinguisher, proper PPE) as needed

- Replace blankets that show significant wear, holes, or degradation

- Never use welding blankets for purposes beyond their specified ratings

Choosing the Right Forney Welding Blanket

Consider these factors when selecting your blanket:

- Workpiece size:Larger projects need bigger coverage areas

- Welding type:Some processes generate more sparks than others

- Workspace layout:Account for nearby walls, floors, and equipment

- Frequency of use:Heavy-duty applications may require thicker materials

The Forney welding blanket is an essential safety tool for any welding operation. By understanding its features, proper use, and maintenance requirements, you can create a safer work environment while protecting your valuable equipment and surroundings from heat damage.