Neoprene Welding Blanket Guide: Safety & Heat Protection Solutions

Summary:Neoprene welding blankets protect surfaces from sparks, heat, and molten metal during welding. This guide explains their benefits, proper use cases, material properties, and how they compare to other welding protection methods.

What Is a Neoprene Welding Blanket?

When you're welding, sparks and molten metal can damage nearby surfaces. A neoprene welding blanket creates a protective barrier between your work area and flammable materials. Unlike fiberglass or leather alternatives, neoprene offers unique advantages:

- Flexible yet durable synthetic rubber material

- Resists temperatures up to 400°F (204°C)

- Waterproof and chemical-resistant surface

- Lightweight compared to metal welding curtains

Key Benefits for Welders

You'll appreciate these practical advantages when using neoprene welding blankets:

1. Spark Containment:The dense rubber material stops 98% of welding spatter from reaching protected surfaces. This prevents burn marks on floors, workbenches, or nearby equipment.

2. Heat Resistance:While not for direct contact with flames, neoprene effectively blocks radiant heat from damaging sensitive materials underneath.

3. Easy Maintenance:Simply wipe clean with a damp cloth - no special cleaning solutions required. The non-porous surface prevents slag buildup.

Proper Usage Techniques

To get maximum protection from your neoprene welding blanket:

- Cover the entire work area with at least 12 inches of overlap on all sides

- Secure edges with magnetic weights or non-flammable clamps

- Inspect regularly for thinning spots or chemical damage

- Store flat or rolled (never folded) to prevent crease damage

Note: Neoprene works best for MIG and TIG welding. For plasma cutting or oxy-fuel work, consider heavier asbestos-free alternatives.

Material Comparison

| Material | Max Temp | Weight | Best For |

|---|---|---|---|

| Neoprene | 400°F | Light | General welding |

| Fiberglass | 1000°F | Medium | Heavy-duty work |

| Leather | 500°F | Heavy | Mobile applications |

Safety Considerations

While neoprene welding blankets improve safety, remember:

- Never use as personal protective equipment (PPE) - wear proper welding gear

- Replace if you notice cracking, hardening, or reduced flexibility

- Keep away from open flames - neoprene can melt at extreme temperatures

- Ensure proper ventilation when welding near neoprene materials

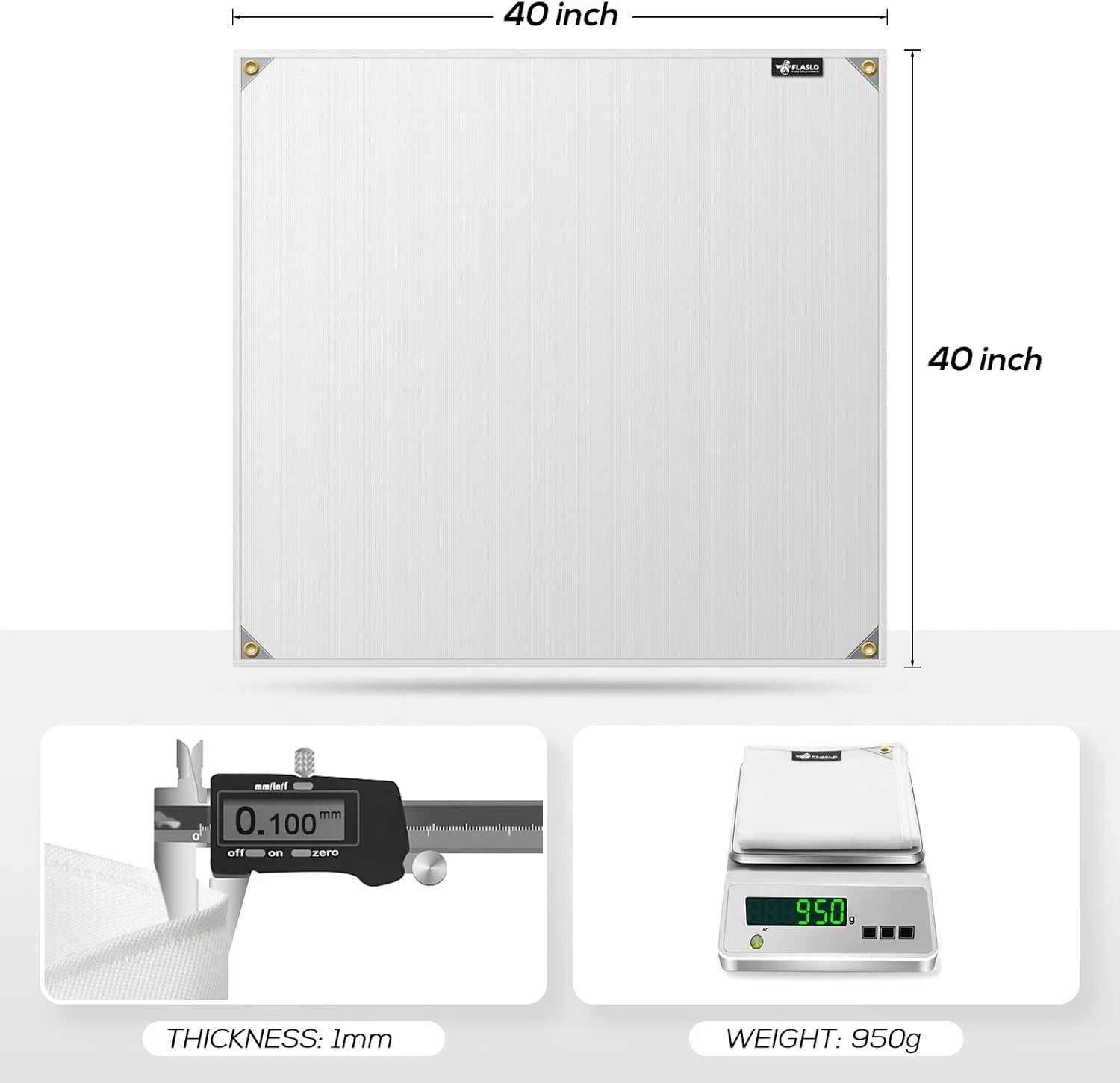

Choosing the Right Size

Measure your work area and add 2 feet of coverage on all sides. Common sizes include:

- 4' x 6' for small bench work

- 6' x 8' for vehicle welding

- 8' x 10' for industrial applications

For irregular shapes, some manufacturers offer custom-cut neoprene welding blankets.

FAQs

Q: Can I wash my neoprene welding blanket?A: Yes, use mild soap and cold water. Never machine wash or dry.

Q: How long do they typically last?A: With proper care, 3-5 years of regular use.

Q: Are there eco-friendly options?A: Some brands now offer recycled neoprene welding blankets.