Acrylic Coated Fiberglass Welding Blanket: Ultimate Heat Protection for Industrial Safety

This guide explains how acrylic coated fiberglass welding blankets protect against sparks, slag, and heat. You'll learn their benefits, uses, and how to choose the right one for your welding projects.

What Is an Acrylic Coated Fiberglass Welding Blanket?

An acrylic coated fiberglass welding blanket is a heat-resistant safety tool. It's made from woven fiberglass with an acrylic coating. This combination creates a durable barrier against welding sparks, molten metal, and high temperatures up to 1000°F (538°C). Unlike regular fiberglass blankets, the acrylic coating adds extra protection and makes the blanket easier to clean.

Key Benefits of Using Acrylic Coated Blankets

When you use an acrylic coated fiberglass welding blanket, you get several advantages:

- Superior heat resistance- Withstands direct flame and intense welding heat

- Spark and slag protection- Prevents fire hazards in your workspace

- Durable surface- The acrylic coating resists tears and abrasions

- Easy maintenance- Wipe clean with a damp cloth after use

- Flexible use- Can be cut to size without fraying edges

Common Applications in Welding and Beyond

You'll find acrylic coated fiberglass welding blankets useful for:

- Protecting floors and walls in welding shops

- Covering valuable equipment near welding areas

- Creating safe zones for hot work in construction

- Automotive repair and exhaust work

- Foundry applications and metal casting

Many professionals also use them for fireproofing during grinding, cutting, or brazing operations.

How to Choose the Right Welding Blanket

When selecting your acrylic coated fiberglass welding blanket, consider these factors:

- Temperature rating- Match it to your typical welding temperatures

- Thickness- Thicker blankets (1/8" or more) offer better protection

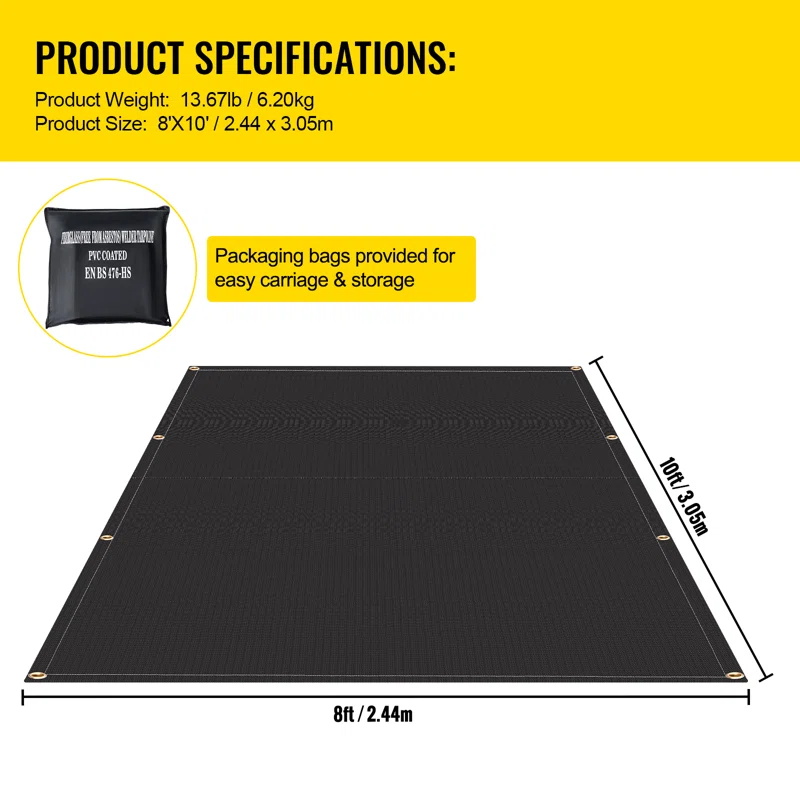

- Size- Measure your work area to ensure proper coverage

- Coating quality- Look for evenly distributed acrylic coating

- Edge treatment- Reinforced edges last longer

Proper Care and Maintenance Tips

To extend your acrylic coated fiberglass welding blanket's life:

- Shake off loose debris after each use

- Wipe with a damp cloth for stubborn residue

- Store flat or rolled in a dry place

- Inspect regularly for tears or thin spots

- Replace when the coating wears significantly

Never machine wash or use harsh chemicals that could damage the acrylic coating.

Safety Precautions When Using Welding Blankets

While acrylic coated fiberglass welding blankets provide excellent protection, remember:

- They're not fireproof - prolonged direct flame contact can damage them

- Always wear proper PPE (gloves, goggles) when handling hot materials

- Keep blankets away from electrical sources

- Don't use damaged blankets - replace them immediately

- Ensure proper ventilation when welding under covered areas

Comparing Acrylic Coated vs. Other Welding Blankets

Unlike silicone coated or uncoated fiberglass blankets, acrylic coated versions offer:

| Feature | Acrylic Coated | Silicone Coated | Uncoated |

|---|---|---|---|

| Heat Resistance | Up to 1000°F | Up to 1200°F | Up to 800°F |

| Durability | High | Very High | Medium |

| Cost | Moderate | High | Low |

| Cleaning Ease | Easy | Moderate | Difficult |

For most general welding applications, acrylic coated blankets provide the best balance of protection and value.

Where to Buy Quality Acrylic Coated Fiberglass Welding Blankets

You can find these blankets at welding supply stores, industrial safety retailers, and online marketplaces. Look for reputable brands that specify material composition and temperature ratings. Always check customer reviews for real-world performance feedback before purchasing.

Conclusion

An acrylic coated fiberglass welding blanket is an essential safety tool for any welding professional. It offers reliable protection against heat and sparks while being durable and easy to maintain. By choosing the right blanket and using it properly, you can significantly improve worksite safety and protect valuable equipment from welding hazards.