Sealey Welding Blanket Guide: Protection & Safety Tips

Summary:Sealey welding blankets protect against sparks, heat and molten metal. This guide explains their features, proper use cases, safety benefits, and maintenance tips for optimal performance in welding applications.

What Is a Sealey Welding Blanket?

Sealey welding blankets are heat-resistant protective covers made from fiberglass or other durable materials. They shield surfaces from welding sparks, molten metal splatter, and heat damage. Unlike regular tarps, these specialized blankets withstand temperatures up to 1000°C (1832°F).

You'll find Sealey welding blankets in various sizes, typically ranging from 1m x 1m to 2m x 3m. The company offers different models with reinforced edges and grommets for secure installation. Their orange color makes them highly visible in workshop environments.

Key Benefits of Using Sealey Welding Blankets

1. Fire Prevention:The primary purpose is preventing accidental fires by containing sparks and hot debris. Unlike standard fabrics that might ignite, these blankets resist burning.

2. Surface Protection:Place them under your work area to protect floors, workbenches, or vehicles from heat damage and metal spatter that could cause permanent marks.

3. Versatility:Beyond welding, you can use Sealey blankets for grinding, cutting, or any hot work where heat protection is needed. Some models work as emergency fire blankets too.

How to Choose the Right Sealey Welding Blanket

Consider these factors when selecting:

- Size:Measure your work area. Larger blankets (2m x 3m) cover more space but may be harder to handle in tight spots.

- Thickness:Thicker blankets (1.5mm+) offer better protection for heavy-duty welding but are less flexible.

- Material:Fiberglass is standard, but some Sealey models have silicone coatings for extra durability.

- Edge Reinforcement:Look for stitched edges with metal grommets if you need to hang the blanket.

Proper Use and Maintenance

To get the most from your Sealey welding blanket:

Installation:Secure it properly using the grommets or weights. Ensure complete coverage of vulnerable areas with some overlap if using multiple blankets.

Positioning:Keep the blanket at least 1 meter from the actual welding point to prevent direct flame contact. Angle it to deflect sparks downward when possible.

Cleaning:Shake off debris regularly. For deep cleaning, follow Sealey's instructions - some models can be gently hand-washed with mild detergent.

Inspection:Check for holes or thinning areas before each use. Even small damage can compromise protection.

Safety Considerations

While Sealey welding blankets significantly improve safety, remember:

- They don't replace proper PPE (gloves, helmets, etc.)

- Avoid direct contact with the blanket during/after welding - surfaces remain extremely hot

- Never use damaged blankets - replace them immediately if compromised

- Keep flammable materials away even when using blankets

Comparing Sealey to Other Brands

Sealey welding blankets stand out for their:

- Consistent quality control

- Clear temperature ratings

- Reinforced edges that resist fraying

- UV resistance for outdoor use

While slightly more expensive than generic options, they offer better longevity and reliable protection for professional use.

Where to Use Sealey Welding Blankets

Common applications include:

- Automotive repair shops (protecting vehicle interiors during welding)

- Construction sites (covering flammable materials)

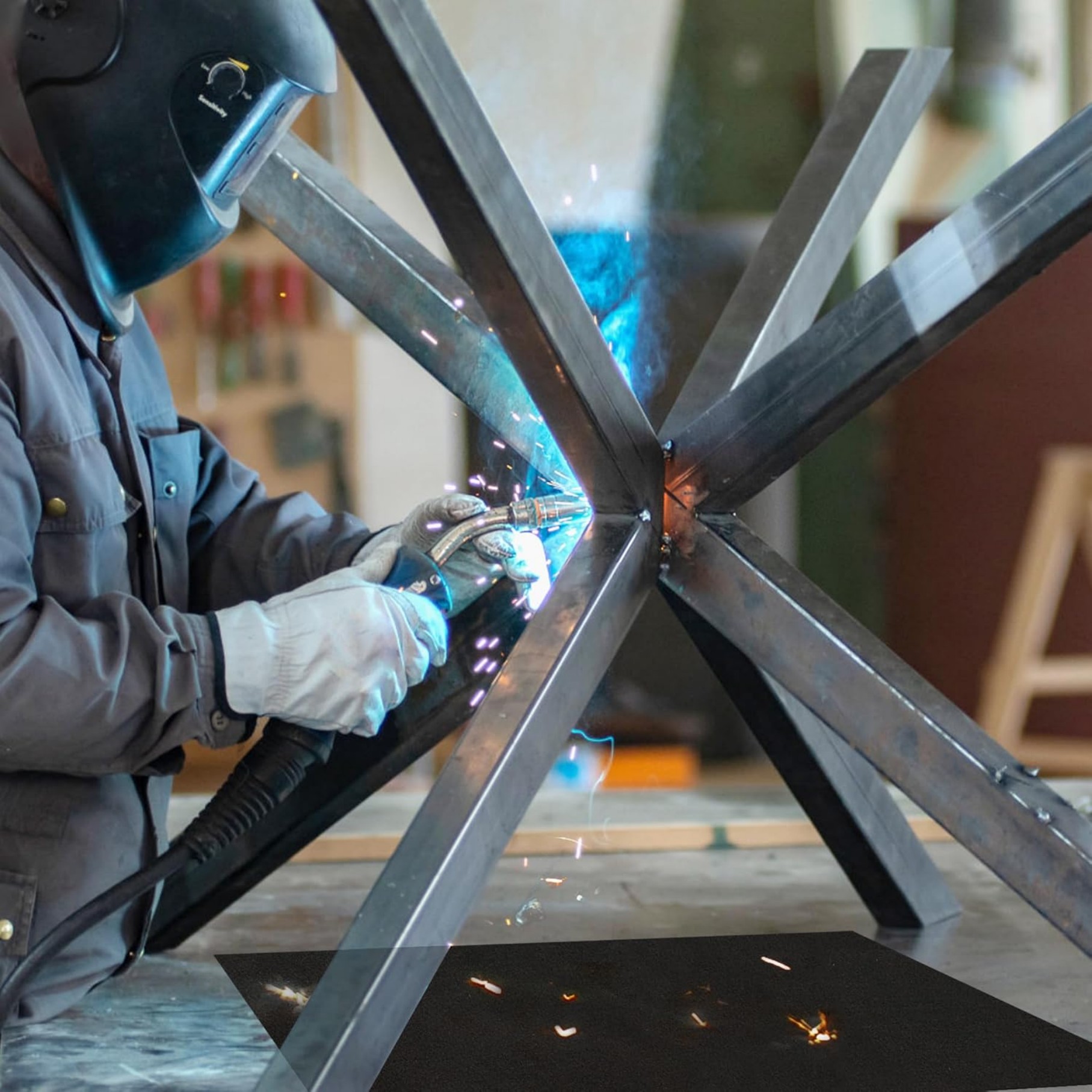

- Metal fabrication workshops

- DIY projects at home

- Emergency fire containment

Conclusion

A Sealey welding blanket is a wise investment for anyone performing hot work. By understanding their proper use and limitations, you can significantly improve workshop safety and protect valuable equipment. Always follow manufacturer guidelines and replace blankets showing wear to maintain optimal protection.