Fiberglass Welding Blanket: Essential Protection for Hot Work Safety

Summary:Fiberglass welding blankets provide critical heat and spark protection during welding, cutting, and grinding. These durable, heat-resistant covers shield workers and surfaces from burns, sparks, and molten metal splatter.

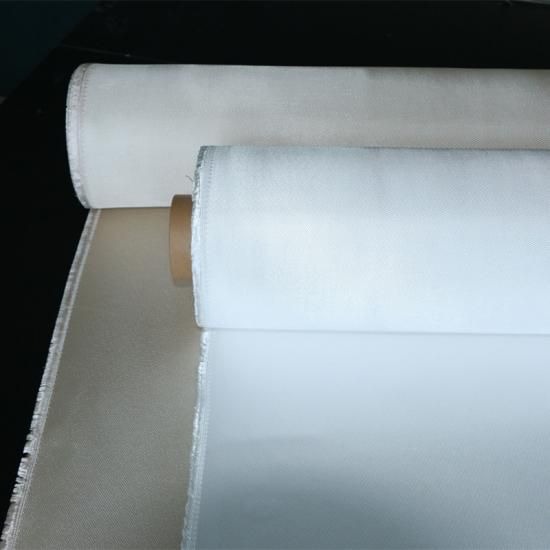

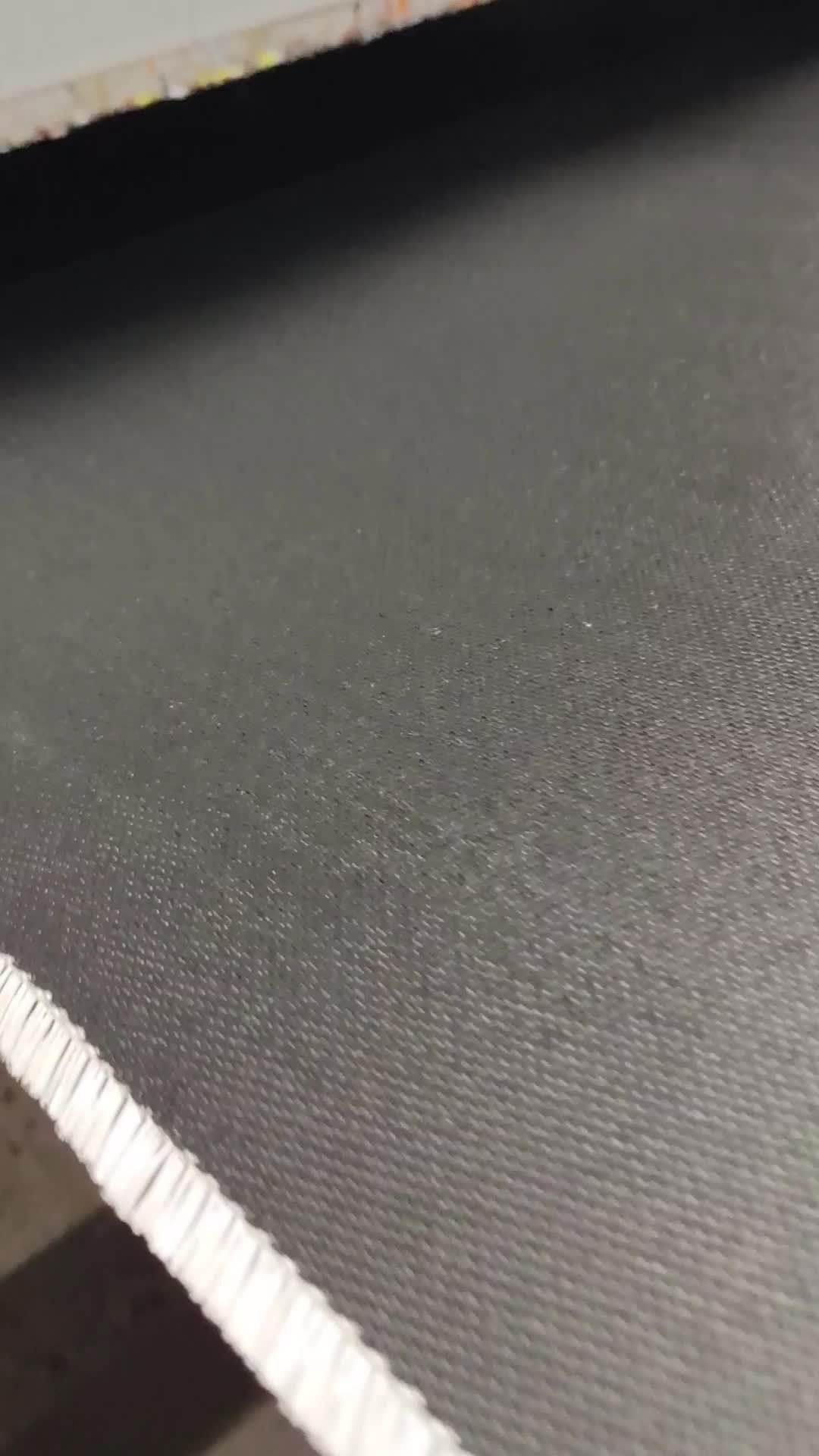

What Is a Fiberglass Welding Blanket?

When you're working with high temperatures, a fiberglass welding blanket becomes your first line of defense. These specialized covers are woven from fiberglass yarns, often coated with silicone or other heat-resistant materials. Unlike regular fabrics, they can withstand temperatures up to 1,000°F (538°C) or higher depending on the specific product.

Key Benefits You Should Know

Why choose fiberglass over other materials? Here's what makes these blankets essential:

- Extreme heat resistance:Protects against direct flame contact and radiant heat

- Spark and slag protection:Contains dangerous welding byproducts

- Durability:Resists tears and abrasions better than standard fabrics

- Flexibility:Can be draped over irregular surfaces or used as curtains

- Reusable:Unlike disposable covers, these last through multiple jobs

How to Use Your Welding Blanket Properly

Simply having a fiberglass welding blanket isn't enough - you need to use it correctly:

- Inspect your blanket before each use for tears or excessive wear

- Cover all flammable surfaces within at least 35 feet of your work area

- Overlap multiple blankets if your coverage area is large

- Secure edges with weights or clamps to prevent movement

- Keep the blanket clean - accumulated debris can become flammable

Choosing the Right Blanket for Your Needs

Not all fiberglass welding blankets are equal. Consider these factors:

| Feature | Standard Grade | Premium Grade |

|---|---|---|

| Temperature Rating | Up to 1,000°F | Up to 1,800°F |

| Coating | None or basic | Silicone or vermiculite |

| Thickness | 1/16" to 1/8" | 1/4" or thicker |

| Best For | Light welding, occasional use | Heavy industrial applications |

Maintenance and Safety Tips

To maximize your fiberglass welding blanket's lifespan and effectiveness:

- Store folded or rolled in a dry location

- Brush off debris after each use - never wash with water

- Replace when you notice significant thinning or holes

- Always wear gloves when handling used blankets - fibers can irritate skin

- Keep fire extinguishers accessible even when using blankets

Common Applications Beyond Welding

While designed for welding, these versatile blankets work well for:

- Foundry work and metal casting operations

- Fireplace and wood stove protection

- Automotive exhaust system repairs

- Protecting floors during hot roofing work

- Emergency fire containment

Frequently Asked Questions

Q: Can I cut my fiberglass welding blanket to size?A: Yes, but seal the cut edges with high-temperature silicone to prevent unraveling.

Q: How long do these blankets typically last?A: With proper care, expect 1-3 years of regular use depending on exposure conditions.

Q: Are there any health concerns with fiberglass?A: The fibers can irritate skin and lungs. Always wear gloves and consider coated blankets if concerned.

Q: Can these blankets be used for electrical insulation?A: No - they're designed for thermal protection only and don't provide electrical insulation.