High Temperature Welding Blankets: Protection for Extreme Heat

High temperature welding blankets protect workers and equipment from extreme heat and sparks. These specialized fabrics resist temperatures up to 3000°F while being flexible and durable. Learn how they work, their benefits, and how to choose the right one.

What Are High Temperature Welding Blankets?

High temperature welding blankets are heat-resistant fabrics designed to protect surfaces from sparks, slag, and molten metal during welding operations. Made from materials like fiberglass, silica, or ceramic fibers, these blankets can withstand continuous exposure to extreme temperatures that would destroy ordinary fabrics.

You'll find these blankets in various industries including shipbuilding, pipeline construction, and metal fabrication. Their primary purpose is to create a protective barrier between the intense heat of welding and surrounding flammable materials or sensitive equipment.

Key Features of Quality Welding Blankets

When selecting high temperature welding blankets, look for these essential characteristics:

- Temperature resistance:Ranging from 1000°F to 3000°F depending on material

- Flexibility:Should drape easily over irregular surfaces

- Durability:Resistant to tears, abrasions, and chemical exposure

- Non-conductive:Important for electrical safety in work areas

- Lightweight:Easy to handle and position as needed

Common Materials Used

High temperature welding blankets come in several material types, each with unique properties:

Fiberglass:The most economical option, resistant to temperatures up to 1000°F. Best for light welding tasks and general heat protection.

Silica:Withstands temperatures up to 1800°F. More flexible than fiberglass and resistant to thermal shock.

Ceramic fiber:The highest performance option, handling temperatures up to 3000°F. Used in foundries and heavy industrial applications.

Proper Use and Safety Tips

To get maximum protection from your high temperature welding blanket:

- Inspect blankets regularly for tears or damage

- Ensure complete coverage of protected areas with overlap

- Keep blankets clean from oil and grease buildup

- Store properly when not in use to prevent unnecessary wear

- Never use damaged blankets - replace them immediately

Remember that while these blankets provide excellent heat protection, they don't eliminate all welding hazards. You should still wear appropriate personal protective equipment (PPE) including gloves, helmets, and flame-resistant clothing.

Choosing the Right Blanket for Your Needs

Selecting the appropriate high temperature welding blanket depends on several factors:

Temperature requirements:Match the blanket's rating to your maximum expected heat exposure. It's better to choose a blanket rated higher than your typical working temperatures.

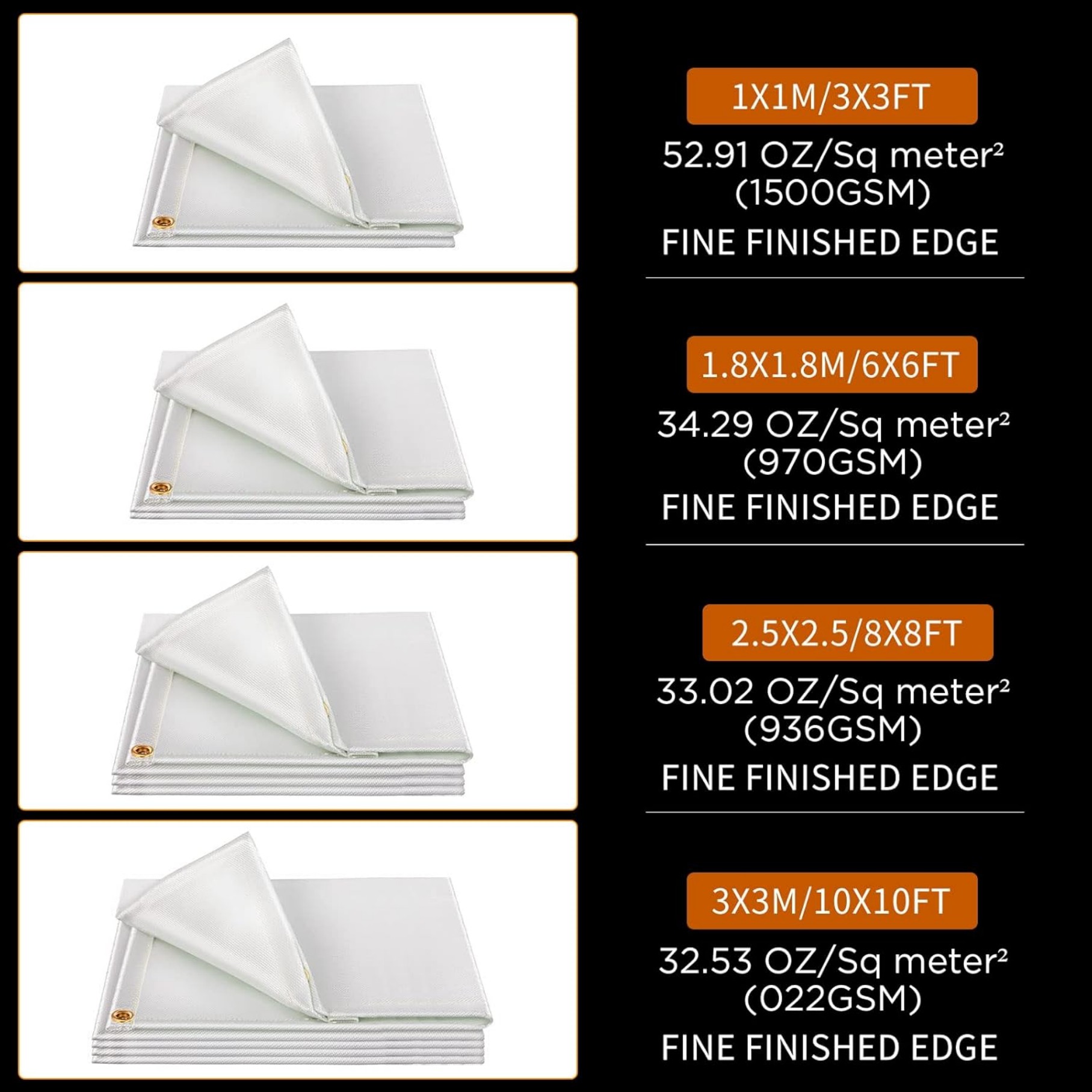

Size and shape:Measure the area you need to protect. Many blankets can be custom-cut to fit specific equipment or work areas.

Attachment method:Some blankets come with grommets for easy hanging, while others are designed to drape freely. Consider how you'll secure the blanket in place.

Chemical exposure:If your work environment includes chemical splashes, look for chemically resistant coatings.

Maintenance and Care

Proper care extends the life of your high temperature welding blankets:

- Shake out debris after each use

- Wash only when necessary using mild detergent (check manufacturer instructions)

- Air dry completely before storage

- Fold carefully to prevent creasing that could weaken fibers

- Store in a clean, dry area away from direct sunlight

With proper selection and care, high temperature welding blankets provide reliable protection that improves worksite safety and protects valuable equipment from heat damage. Investing in quality blankets tailored to your specific needs will pay off in long-term performance and safety benefits.