Damaged Welding Blanket: Safety Risks and Proper Maintenance Guide

A damaged welding blanket compromises safety in your workshop. This guide explains how to identify wear, assess risks, and choose the right replacement to protect against sparks, heat, and molten metal during welding operations.

Why a Damaged Welding Blanket Puts You at Risk

Your welding blanket serves as the first line of defense against workplace hazards. When it's damaged, several risks emerge:

- Reduced heat resistance:Holes or thin spots allow extreme temperatures to penetrate

- Spark penetration:Molten metal can pass through tears, igniting nearby materials

- Electrical hazards:Compromised insulation increases shock risks

- UV radiation exposure:Gaps in coverage fail to block harmful welding rays

Never use a welding blanket that shows visible damage - the cost of replacement is far less than medical bills or property damage from an accident.

How to Inspect Your Welding Blanket for Damage

Regular inspection helps catch problems before they become dangerous. Follow this 5-step check:

- Visual examination:Lay the blanket flat and look for holes, tears, or thinning areas

- Flex test:Gently bend the material - excessive stiffness indicates degradation

- Edge inspection:Check grommets and borders where wear often starts

- Light test:Hold up to bright light - significant light penetration means replacement time

- Performance check:Notice if sparks now pass through areas that previously blocked them

Common Causes of Welding Blanket Damage

Understanding what damages your welding blanket helps prevent premature failure:

- Contact with sharp edges:Dragging across metal corners creates tears

- Chemical exposure:Solvents and acids degrade protective coatings

- Improper storage:Folding the same way repeatedly weakens fibers

- Excessive heat:Prolonged exposure beyond rated temperatures

- Mechanical stress:Using blankets as floor coverings accelerates wear

Choosing the Right Replacement Welding Blanket

When your current blanket shows damage, consider these factors for your replacement:

Material Options

- Fiberglass:Most common, good for general welding (up to 1000°F)

- Silica:Higher heat resistance (up to 1800°F), more flexible

- Carbon fiber:Extreme heat applications (up to 3000°F), more expensive

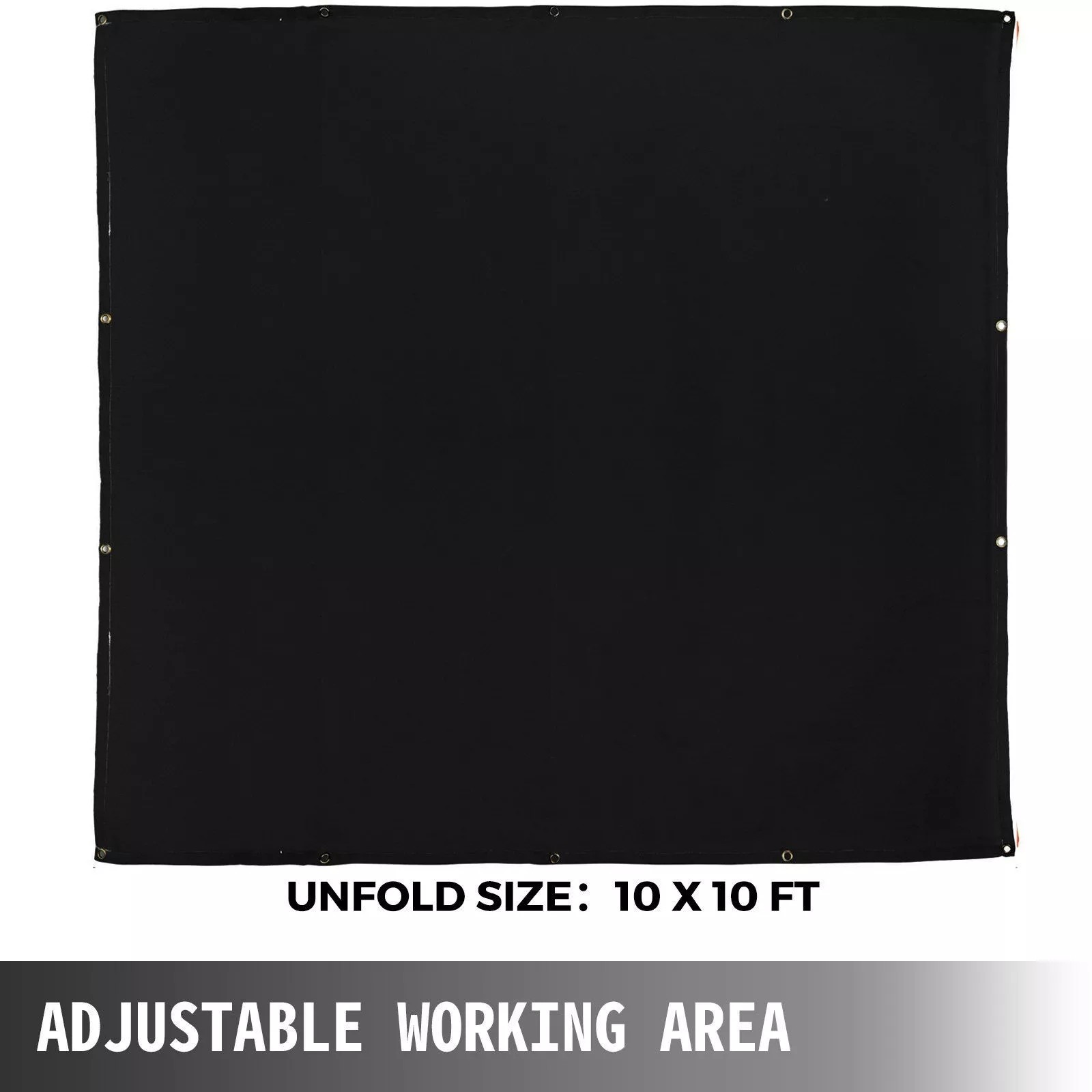

Size and Thickness

Measure your work area and choose coverage that allows at least 12 inches of overlap on all sides. Thickness typically ranges from 1/16" to 1/4" - thicker blankets last longer but are less flexible.

Special Features

- Reinforced edges with metal grommets for hanging

- Multi-layer construction for added durability

- Chemical-resistant coatings for specific work environments

Invest in a slightly larger and higher-rated blanket than you currently need - this provides a safety margin and extends service life.

Proper Care to Extend Your New Welding Blanket's Life

Make your replacement last with these maintenance tips:

- Store hung or rolled - never folded in the same place repeatedly

- Clean with compressed air or soft brush - avoid harsh chemicals

- Rotate usage areas to distribute wear evenly

- Keep away from oil, grease, and solvents that degrade materials

- Inspect monthly and after any incident that might cause damage

When to Absolutely Replace a Damaged Welding Blanket

Immediate replacement is necessary when you notice:

- Holes larger than 1/4 inch in diameter

- Multiple tears compromising over 10% of surface area

- Visible fiber disintegration or powdery residue

- Stiff, brittle areas that crack when flexed

- Discoloration indicating chemical degradation

Remember that welding blankets are consumable safety items - regular replacement is part of proper workshop maintenance. A damaged welding blanket costs less to replace than dealing with the consequences of inadequate protection.