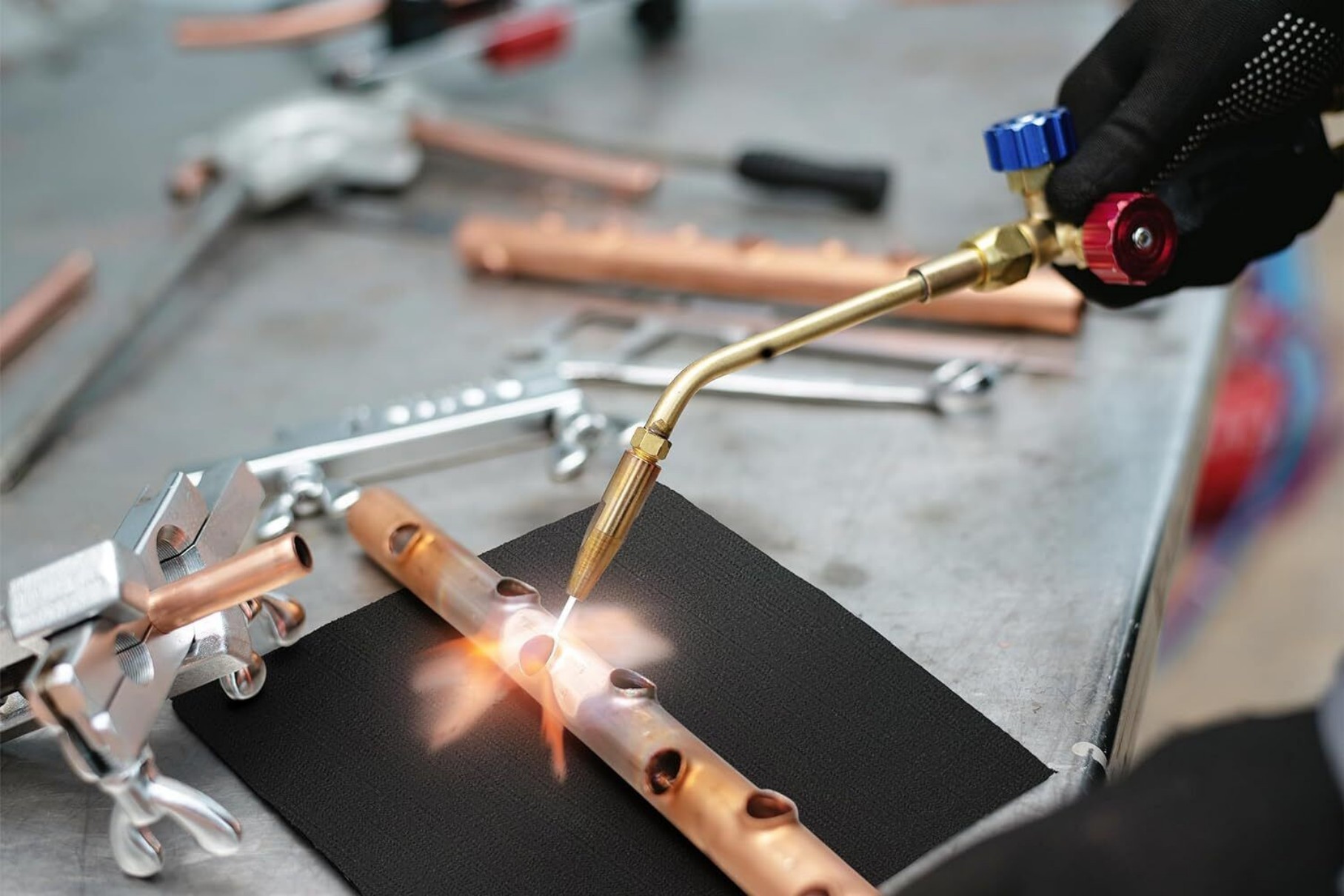

Weld Blanket Roll: Essential Protection for Welding Safety and Efficiency

Weld blanket rolls provide crucial protection against sparks, spatter, and heat during welding operations. This guide explains their benefits, materials, proper usage, and maintenance to enhance your workplace safety and productivity.

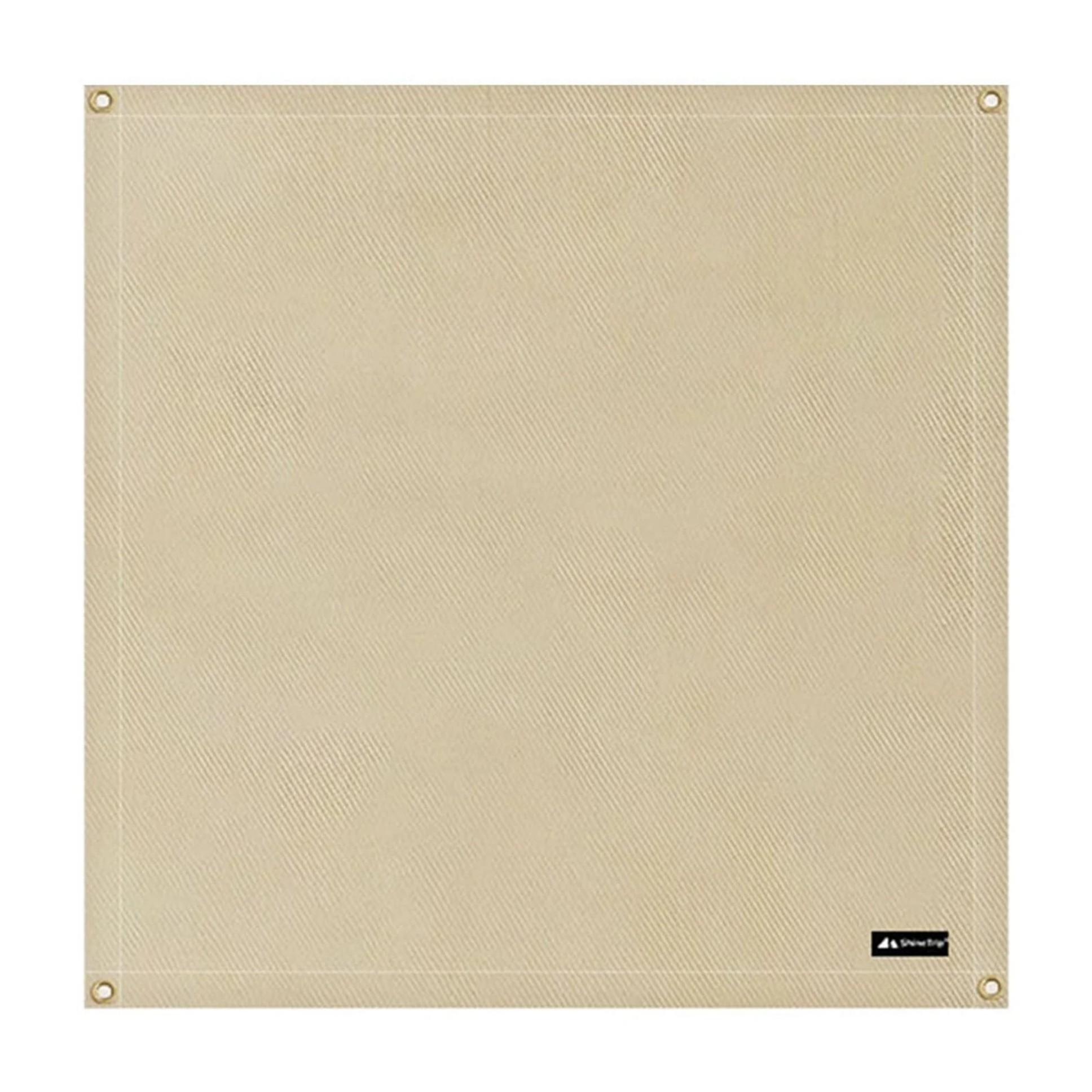

What is a Weld Blanket Roll?

A weld blanket roll is a flexible, heat-resistant protective material designed to shield surrounding areas from welding hazards. Unlike pre-cut blankets, the roll format allows you to cut custom sizes for specific applications. These blankets typically consist of fiberglass, silica, or other refractory materials that can withstand extreme temperatures up to 2000°F (1093°C).

Key advantage:The roll format offers versatility - you can cut precisely what you need for each job, reducing waste and saving money compared to pre-sized blankets.

Why You Need Weld Blanket Rolls in Your Workshop

Welding generates intense heat, sparks, and molten metal that can damage equipment, start fires, or cause injuries. Here's why weld blanket rolls should be part of your safety protocol:

- Fire prevention:Protects flammable materials from sparks and spatter

- Equipment protection:Shields sensitive machinery and electronics

- Work area containment:Creates safe boundaries for welding operations

- Versatility:Adaptable to various project sizes and shapes

- Cost-effective:Reduces material waste compared to pre-cut blankets

Choosing the Right Weld Blanket Roll

Not all weld blanket rolls are equal. Consider these factors when selecting:

Material Types

- Fiberglass:Most common, economical option (resists temperatures up to 1000°F/538°C)

- Silica:Higher temperature resistance (up to 2000°F/1093°C), more durable

- Ceramic fiber:For extreme heat applications (up to 2300°F/1260°C)

Thickness Considerations

Thicker blankets (1/4" or more) offer better protection for heavy-duty welding but are less flexible. Thinner options (1/8") work well for light welding and offer better drape around complex shapes.

Size Options

Common weld blanket roll widths range from 36" to 72", with lengths typically 25-50 feet. Choose based on your typical project sizes to minimize cutting waste.

Proper Installation and Usage Tips

To maximize protection from your weld blanket roll:

- Always overlap sections by at least 6 inches when covering large areas

- Secure edges with welding clamps or high-temperature tape

- Allow at least 12 inches of clearance from the welding arc

- Replace blankets showing significant wear, holes, or carbonization

- Store rolls vertically in a dry location when not in use

Pro tip:For overhead protection, use a double layer of weld blanket with the seams offset for complete coverage.

Maintenance and Care

Proper care extends your weld blanket roll's lifespan:

- Shake out or vacuum loose debris regularly

- Inspect for damage after each use

- Store in a clean, dry area away from moisture

- Never fold or crease the material sharply - roll loosely

- Wash only if absolutely necessary, using mild detergent and cold water

Beyond Welding: Additional Uses

While designed for welding, these versatile rolls have other applications:

- Foundry work and metal casting protection

- Heat shielding in automotive applications

- Fireproofing temporary work areas

- Protecting surfaces during grinding or cutting operations

- Emergency heat barriers in industrial settings

Safety First: Important Precautions

While weld blanket rolls significantly improve safety, remember:

- They are not substitutes for proper PPE (always wear welding helmet, gloves, etc.)

- Never use damaged or contaminated blankets

- Allow blankets to cool completely before handling or storing

- Follow all manufacturer's temperature ratings and usage guidelines

- Maintain proper ventilation even when using blankets

Conclusion

A quality weld blanket roll is an indispensable tool for any welding operation. By choosing the right material and size for your needs, installing it properly, and maintaining it well, you'll create a safer work environment while protecting valuable equipment. The flexibility of the roll format ensures you always have the right amount of protection for each job, making it a smart investment for professional welders and hobbyists alike.