Welding Screen vs Welding Blanket: Key Differences & Best Uses

When choosing between welding screens and welding blankets, you need to consider protection level, mobility, and work environment. This guide compares their features, safety ratings, and ideal applications to help you select the right solution.

What Is a Welding Screen?

A welding screen is a rigid or semi-rigid barrier designed to contain sparks, UV radiation, and heat from welding operations. Typically made from flame-resistant materials like tempered glass or treated polycarbonate, welding screens offer:

- Permanent protectionin fixed workstations

- Clear visibilitythrough transparent panels

- Structural stabilitythat won't blow away

- Reusableconstruction that lasts years

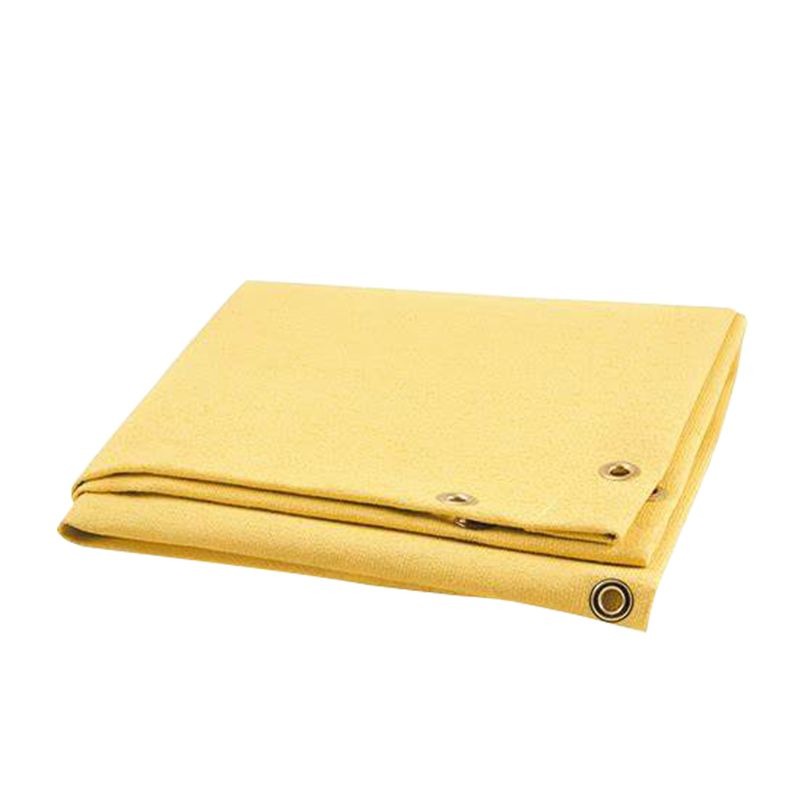

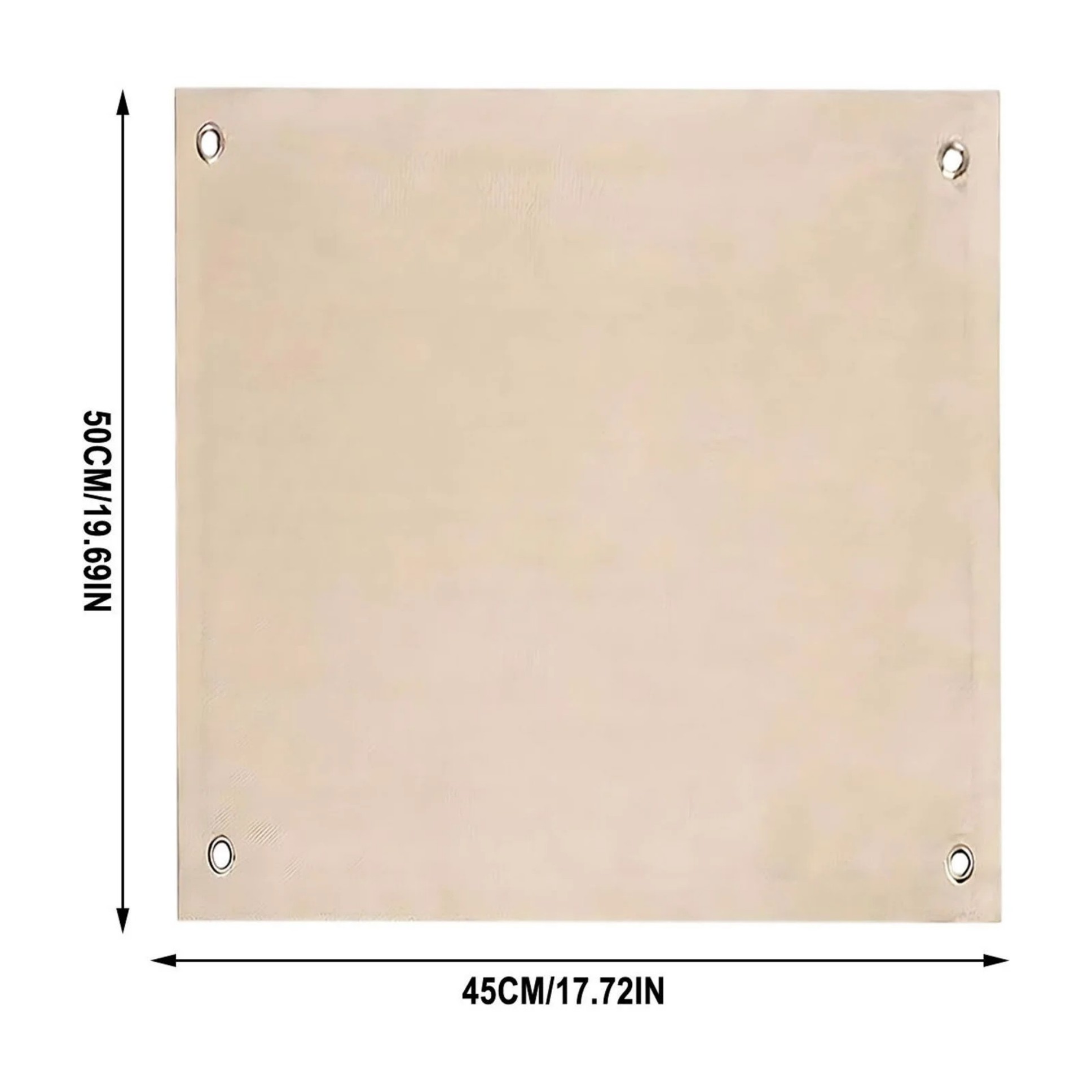

What Is a Welding Blanket?

Welding blankets are flexible protective covers made from materials like fiberglass, silica, or ceramic fabrics. These portable safety solutions provide:

- Adaptable coveragefor irregular shapes

- Temporary protectionfor job sites

- Heat resistanceup to 3000°F (1650°C)

- Lightweightand foldable storage

Key Differences: Welding Screen vs Welding Blanket

Durability:Screens withstand repeated use better than blankets, which degrade over time from folding and spark exposure.

Visibility:Transparent screens allow monitoring of the welding process, while blankets block all visibility.

Installation:Blankets drape instantly over objects; screens require framing or mounting hardware.

Portability:Blankets win for mobile applications; screens are better for permanent stations.

When to Choose a Welding Screen

Opt for welding screens when you need:

- Permanent protection in high-traffic areas

- Visibility of the welding process (critical for supervision)

- Protection against flying debris in addition to sparks

- Compliance with OSHA standards for fixed workstations

When to Choose a Welding Blanket

Welding blankets excel in these situations:

- Temporary job sites or mobile welding operations

- Protecting sensitive equipment or materials nearby

- Irregularly shaped objects that need coverage

- Emergency spark containment (keep one in your welding cart)

Safety Considerations for Both Options

Whether using welding screens or blankets:

- Verify the product meets ANSI/AWS safety standards

- Check temperature ratings match your welding processes

- Inspect regularly for damage (holes in blankets, cracks in screens)

- Combine with other PPE like helmets and gloves

Maintenance and Care Tips

For welding screens:Clean transparent panels with approved cleaners to maintain visibility. Check mounting hardware regularly.

For welding blankets:Shake out debris after use. Store flat or loosely rolled to prevent material fatigue. Replace when fibers become brittle.

Cost Comparison

While welding screens have higher upfront costs ($200-$800), they last 5-10 years with proper care. Welding blankets ($50-$300) typically need replacement every 1-3 years depending on usage frequency.

Final Recommendation

For most welding shops, having both solutions available provides optimal flexibility. Use welding screens for your primary workstations and keep blankets for mobile applications or secondary protection. Always prioritize products with certified safety ratings regardless of which option you choose.