Eco-Friendly Natural Fiber Welding Blankets for Sustainable Protection

Summary:Natural fiber welding blankets provide sustainable heat protection using eco-friendly materials like cotton, wool, or jute. They're ideal for welding, foundries, and industrial applications where fire resistance and environmental responsibility matter.

What Are Natural Fiber Welding Blankets?

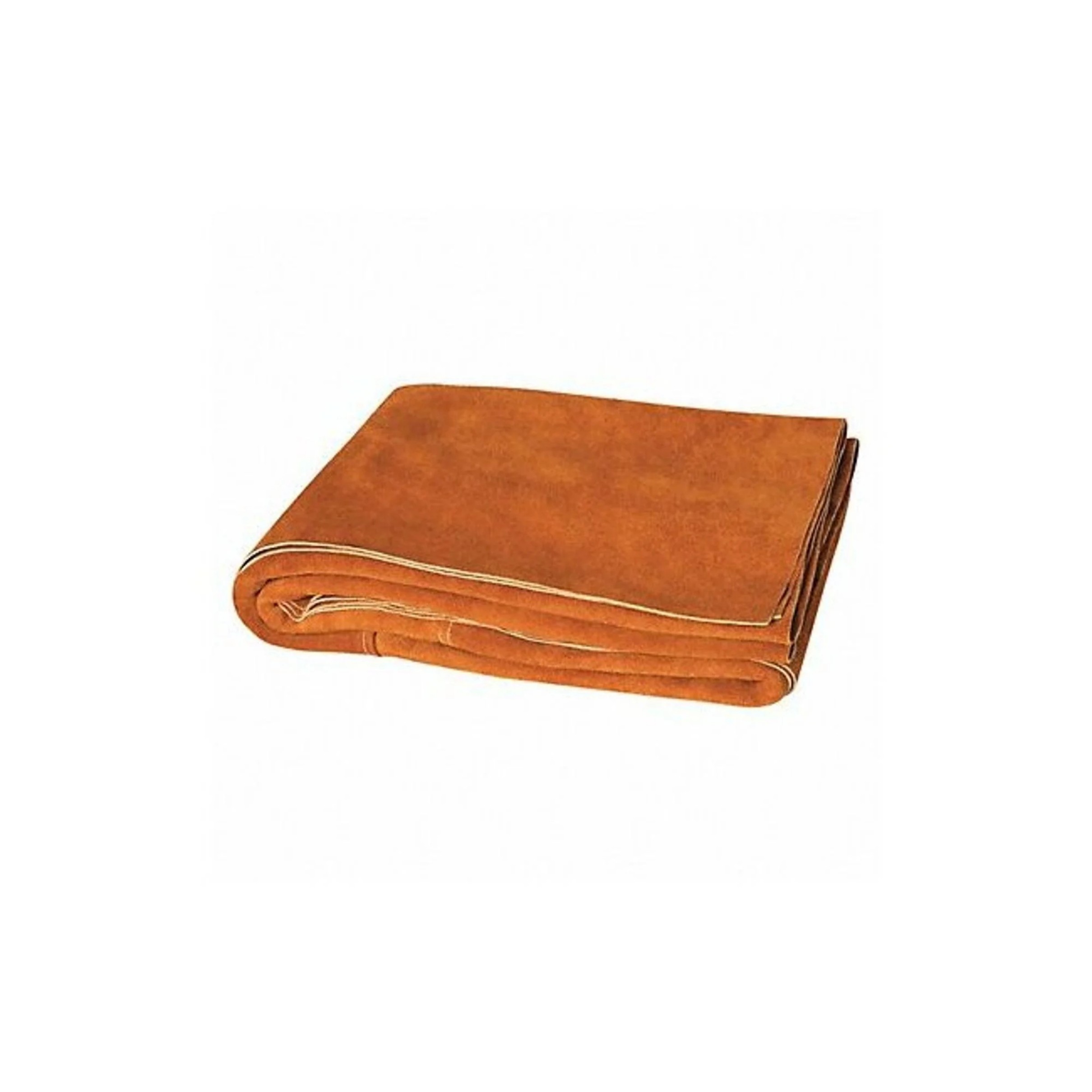

Natural fiber welding blankets are protective covers made from plant-based or animal-derived materials like cotton, wool, jute, or hemp. Unlike synthetic alternatives, these blankets offer fire resistance while being biodegradable and environmentally friendly. You'll find them in welding shops, metalworking facilities, and any place where sparks or heat need containment.

Key Benefits of Using Natural Fiber Blankets

When you choose natural fiber welding blankets, you get several advantages:

- Sustainability:Made from renewable resources that decompose naturally

- Heat resistance:Natural fibers like wool can withstand temperatures up to 1,000°F

- Breathability:Better airflow than synthetic materials reduces heat buildup

- Non-toxic:Won't release harmful fumes when exposed to heat

- Versatility:Useful for welding, grinding, fire protection, and more

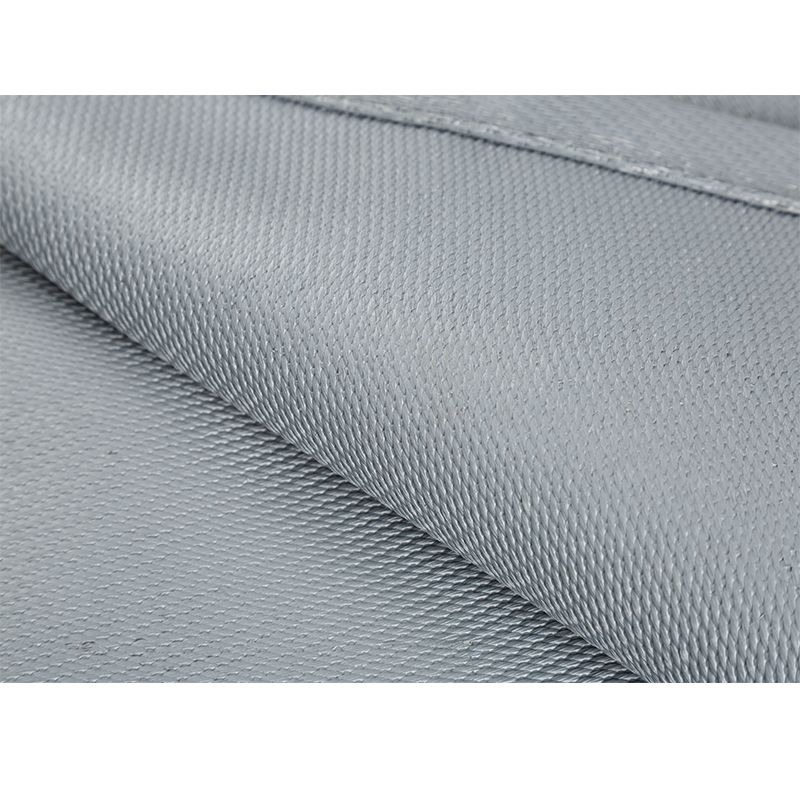

How Natural Fiber Blankets Compare to Synthetic Options

While synthetic welding blankets (like fiberglass or silica) may offer higher temperature ratings, natural fiber options provide unique benefits that might better suit your needs:

| Feature | Natural Fiber | Synthetic |

|---|---|---|

| Environmental impact | Biodegradable, renewable | Non-biodegradable |

| Temperature resistance | Up to 1,000°F | Up to 2,000°F |

| Breathability | High | Low |

| Cost | Moderate | High |

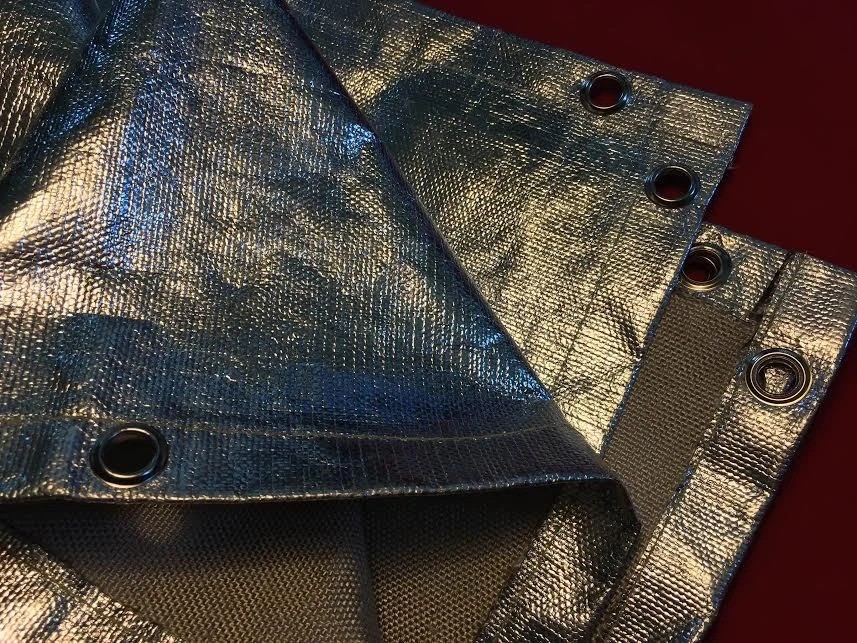

Common Applications for Natural Fiber Welding Blankets

You can use these versatile blankets in various settings:

- Welding protection:Cover nearby surfaces from sparks and spatter

- Foundry work:Protect floors and equipment from molten metal

- Fire prevention:Use as temporary fire barriers in construction

- Automotive work:Protect vehicle interiors during welding repairs

- Art studios:Safeguard surfaces from hot metalworking projects

Choosing the Right Natural Fiber Blanket

When selecting your natural fiber welding blanket, consider these factors:

- Material:Wool offers the highest heat resistance, while cotton is more affordable

- Thickness:Thicker blankets provide better protection but are less flexible

- Size:Measure your work area to ensure proper coverage

- Treatment:Some blankets have fire-retardant treatments for extra safety

- Weight:Heavier blankets stay in place better during work

Care and Maintenance Tips

To extend your natural fiber welding blanket's lifespan:

- Shake out debris after each use

- Spot clean with mild soap and water when needed

- Store in a dry place away from direct sunlight

- Inspect regularly for wear or damage

- Replace when fibers become brittle or protection weakens

Why Choose Natural Over Synthetic?

While synthetic blankets dominate the market, natural fiber welding blankets offer distinct advantages for environmentally conscious users. They provide adequate protection for most welding applications while aligning with green initiatives. If your work involves temperatures below 1,000°F and you value sustainability, these blankets deserve serious consideration.

Remember that proper use matters more than material alone. Always follow safety protocols regardless of which welding blanket you choose. Natural fiber options simply give you an eco-friendly alternative without compromising essential protective qualities.