Non-Fiberglass Welding Blankets: Safer Alternatives for Heat Protection

Summary:Non-fiberglass welding blankets provide safer heat protection without irritating fibers. These durable, high-temperature resistant alternatives offer better comfort and environmental benefits while maintaining excellent spark and slag protection for welding applications.

Why Choose Non-Fiberglass Welding Blankets?

When you're welding, heat protection matters. Traditional fiberglass welding blankets work but shed irritating fibers. Non-fiberglass welding blankets solve this problem with advanced materials that protect just as well without the discomfort. You get the same heat resistance (typically 1000°F to 2000°F) without skin irritation or airborne particles.

Key Benefits of Non-Fiberglass Options

1. No Itchy Fibers:Unlike fiberglass versions, these won't make you scratch. The smooth surface feels better against your skin.2. Easier Cleanup:Without loose fibers, maintenance becomes simpler. Just wipe or shake off debris.3. Durability:Materials like silica or ceramic fabrics resist tears better than traditional fiberglass.4. Environmental Advantage:Many non-fiberglass welding blankets use recyclable materials.

Common Materials Used

Modern non-fiberglass welding blankets use several advanced materials:- Silica Fabric:Withstands up to 2000°F and remains flexible- Ceramic Fiber:Excellent for extreme heat applications- Basalt Fiber:Natural volcanic rock material with great heat resistance- Carbon Fiber:Lightweight yet incredibly strong

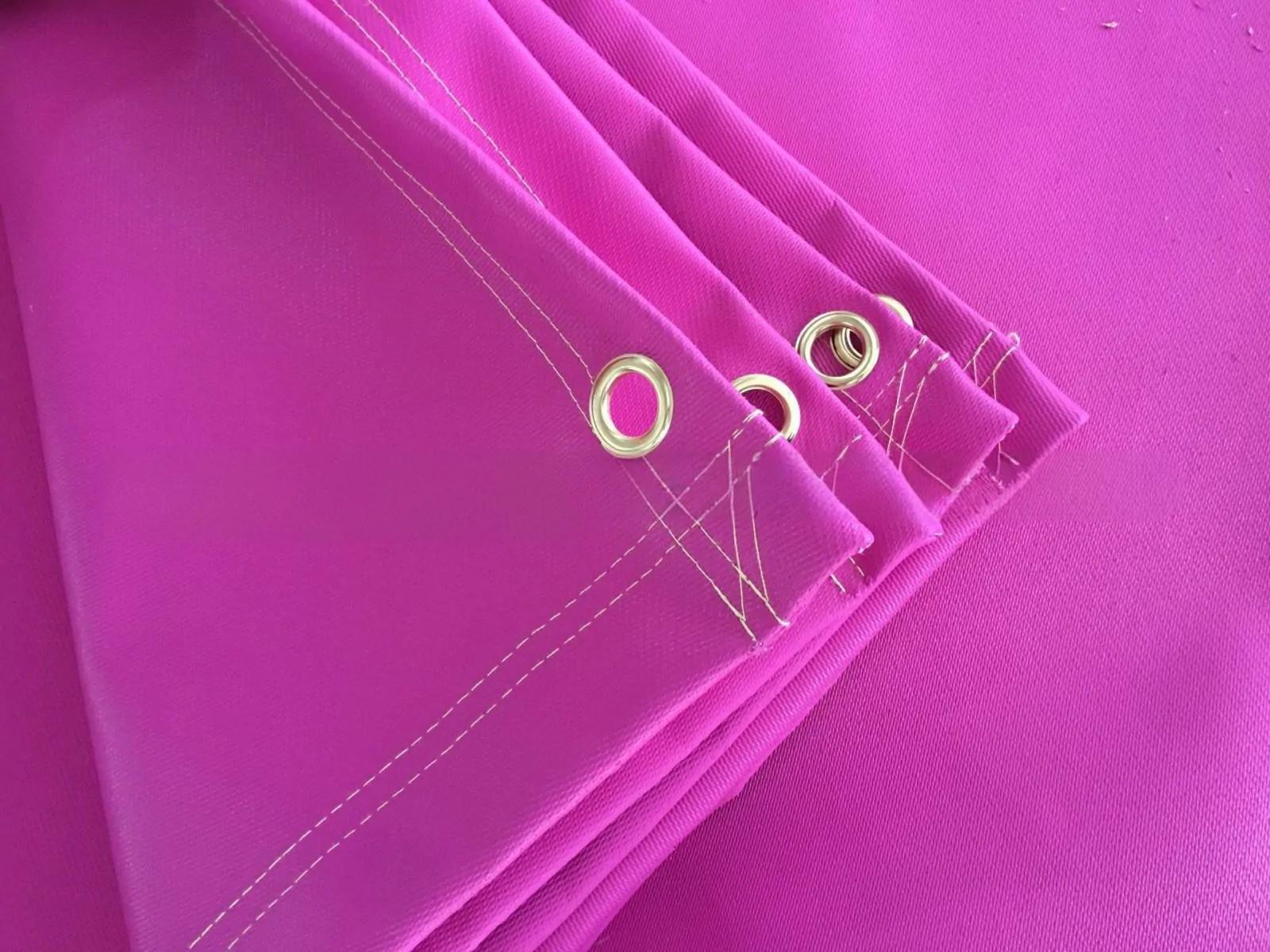

Choosing the Right Blanket

Consider these factors when selecting your non-fiberglass welding blanket:- Temperature Rating:Match it to your typical welding temperatures- Size:Ensure coverage for your work area- Weight:Heavier blankets offer more protection but may be less flexible- Edge Treatment:Look for reinforced edges that resist fraying

Proper Use and Maintenance

To get the most from your non-fiberglass welding blanket:1. Always inspect for damage before use2. Store folded or rolled to prevent creases3. Clean with compressed air or a soft brush4. Replace if you notice significant wear or reduced flexibility

Applications Beyond Welding

These versatile blankets also work well for:- Foundry work- Fire protection- High-temperature insulation

Safety Considerations

While non-fiberglass welding blankets eliminate fiber irritation, remember:- They still get extremely hot during use- Always wear proper PPE underneath- Never use damaged blankets- Allow proper cooling time before handling

Cost Comparison

Non-fiberglass options typically cost 20-30% more than fiberglass but offer:- Longer lifespan- Reduced replacement frequency- Better user comfort- Lower long-term costs through durability

Environmental Impact

Many non-fiberglass welding blankets are:- Made from natural or recycled materials- Fully recyclable at end of life- Produced with lower energy requirements- Free from hazardous materials

Where to Buy Quality Blankets

Look for reputable welding suppliers that:- Provide detailed specifications- Offer temperature ratings from independent testing- Have positive user reviews- Stand behind their products with warranties