Welding Heat Retaining Blanket: Uses, Benefits & How It Works

Summary:A welding heat retaining blanket slows cooling in welded joints, preventing cracks and improving strength. This guide explains how it works, when to use it, and proper application techniques for better weld quality.

What Is a Welding Heat Retaining Blanket?

When you weld metals, rapid cooling creates stresses that can lead to cracks. A welding heat retaining blanket wraps around your workpiece to control cooling rates. These specialized blankets maintain optimal temperatures during the critical post-weld period, typically made from ceramic fibers or other insulating materials that withstand extreme heat.

Why You Need Heat Retention in Welding

Without proper heat control, your welds cool too quickly. This causes two major problems:

- Hydrogen cracking:Fast cooling traps hydrogen in the weld metal

- Brittleness:Rapid temperature drops create hard, fragile microstructures

By using a welding heat retaining blanket, you maintain temperatures between 300-600°F (150-315°C) for the recommended time, allowing proper microstructural development.

Key Applications for Welding Blankets

You'll get the most benefit from heat retaining blankets in these situations:

- High-carbon steel welding (prone to hardening)

- Thick-section welding (greater stress buildup)

- Low-temperature environments (accelerated cooling)

- Critical structural components (where failures matter most)

How to Properly Use Your Welding Heat Retaining Blanket

Follow these steps for effective heat retention:

- Preheat the base metal to recommended temperatures

- Wrap the blanket immediately after completing your weld pass

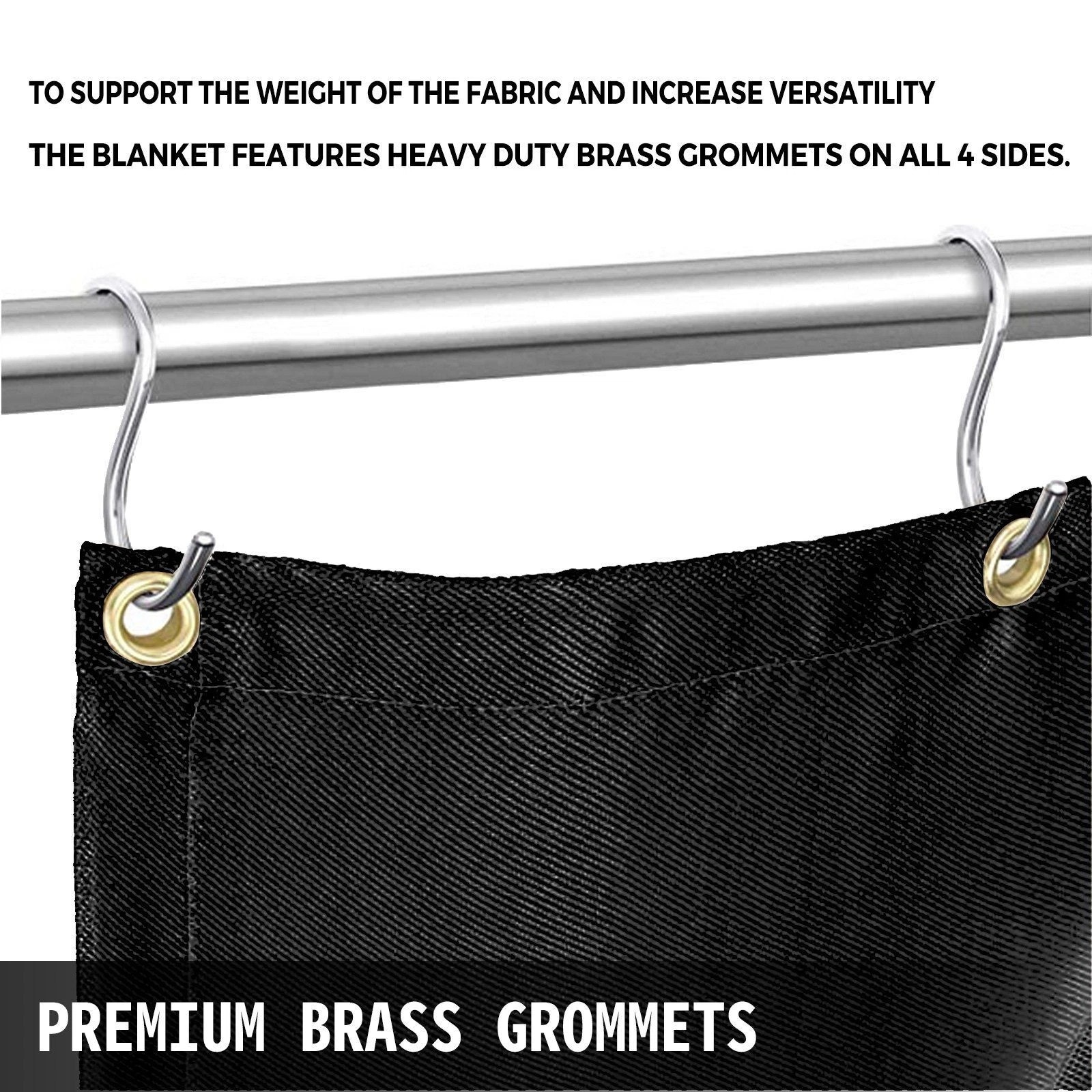

- Secure with stainless steel wire or high-temp straps

- Monitor temperature with a surface pyrometer

- Maintain coverage for the specified post-heat duration

Material Options Compared

| Material | Max Temp | Best For |

|---|---|---|

| Ceramic fiber | 2300°F (1260°C) | High-alloy steels |

| Vermiculite | 1800°F (980°C) | General purpose |

| Fiberglass | 1200°F (650°C) | Aluminum alloys |

Maintenance and Safety Tips

To get the longest life from your welding heat retaining blanket:

- Inspect for tears before each use

- Store flat or rolled (never folded)

- Wear gloves when handling hot blankets

- Replace when insulation efficiency drops by 20%

Never use damaged blankets - exposed fibers can irritate skin and lungs.

Cost vs. Benefit Analysis

While welding heat retaining blankets cost $50-$300 depending on size, they prevent much more expensive problems:

- Reduces rework by up to 40%

- Extends joint service life 2-3 times

- Prevents catastrophic failures in load-bearing structures

FAQs About Welding Heat Retaining Blankets

Q: Can I make my own welding blanket?A: Not recommended. Commercial blankets use specially engineered materials that provide consistent insulation without hazardous fibers.

Q: How long should I keep the blanket on?A: Follow your WPS (Welding Procedure Specification), typically 1 hour per inch (25mm) of thickness.

Q: Can blankets replace post-weld heat treatment?A: For some applications yes, but critical components often require full PWHT. Consult your welding engineer.