Carbonized Fiber Welding Blankets: Heat Protection Solutions for Industrial Safety

Carbonized fiber welding blankets are flame-resistant safety tools for welding, foundries, and high-heat applications. They protect workers and equipment from sparks, slag, and radiant heat up to 2000°F (1093°C). This guide explains their benefits, uses, and selection criteria.

What Are Carbonized Fiber Welding Blankets?

Carbonized fiber welding blankets are made from oxidized or carbonized fibers (like PAN or rayon) treated for extreme heat resistance. Unlike fiberglass, they won't melt or degrade under direct flame exposure. Their woven structure provides flexibility while blocking 90%+ of radiant heat.

Key Advantages Over Traditional Materials

- Higher temperature rating(2000°F vs. fiberglass's 1000°F)

- No melting- carbon fibers char but maintain integrity

- Reusable- withstand repeated thermal cycles

- Lightweight- 50% lighter than ceramic alternatives

- Low thermal conductivity- protects hands during handling

Industrial Applications

You'll find carbonized fiber welding blankets in:

- Pipeline welding- Protecting adjacent sections from spatter

- Shipbuilding- Containing sparks in confined spaces

- Foundry work- Lining ladles and covering molten metal spills

- Aerospace- Shielding composite materials during repairs

- Automotive- Protecting EV batteries during welding

How to Choose the Right Blanket

| Factor | Consideration |

|---|---|

| Temperature | Match blanket's rating to your maximum operating heat |

| Size | Measure coverage area + 20% overlap margin |

| Thickness | 1/8" for general use, 1/4" for prolonged contact |

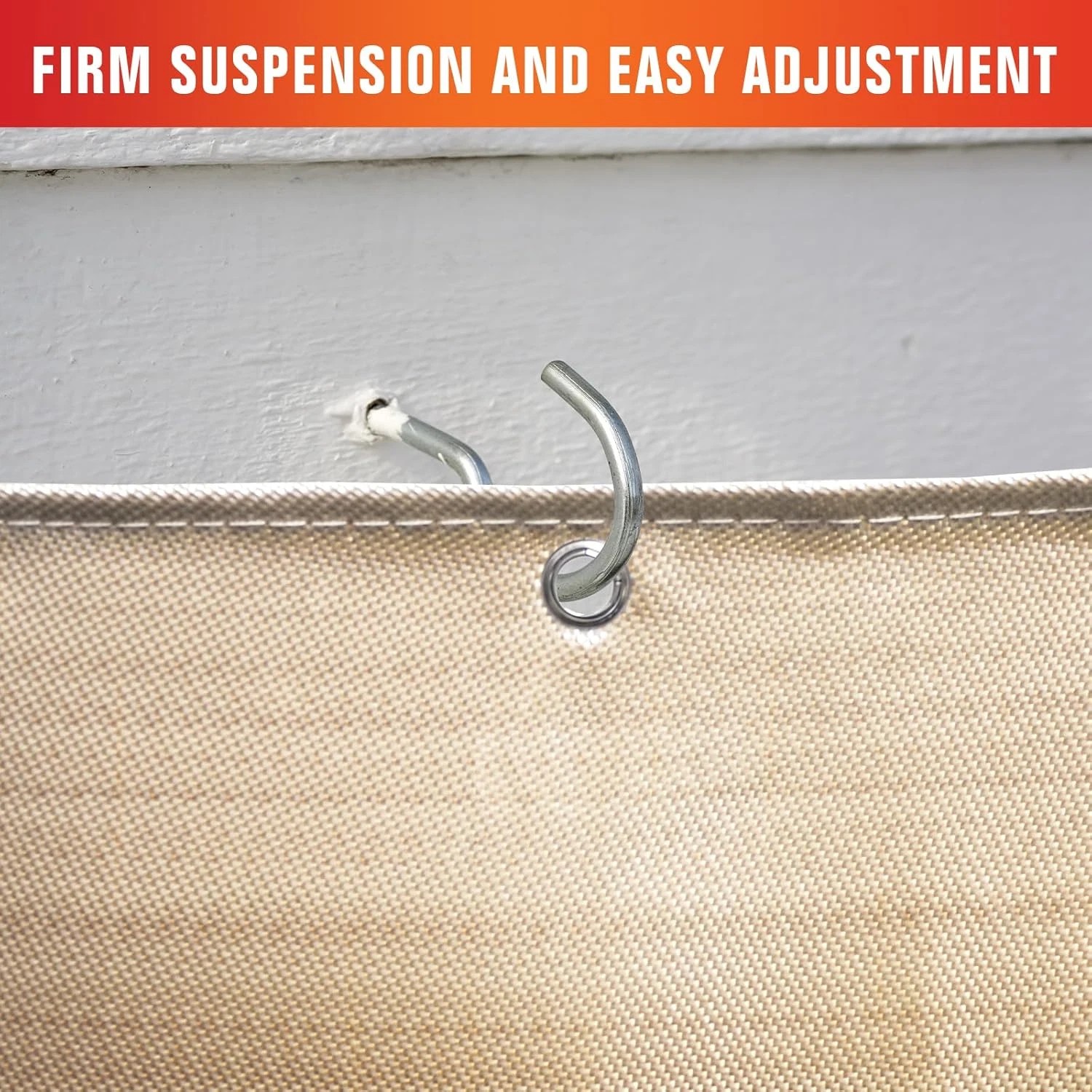

| Edging | Stainless steel grommets for hanging durability |

Maintenance Tips

To extend your carbonized fiber welding blanket's lifespan:

- Brush off slag deposits after each use

- Store flat or rolled (never folded) to prevent fiber breakage

- Inspect for holes - small tears can be patched with high-temp cement

- Wash only when necessary using compressed air or low-pressure water

Safety First: Proper Usage

While carbonized fiber offers superior protection, always:

- Wear heat-resistant gloves when handling hot blankets

- Secure edges with clips to prevent tripping hazards

- Replace blankets showing significant fiber degradation

- Never use as personal PPE - these are equipment protectors

Innovations in Carbonized Fiber Technology

Recent advancements include:

- Silicon carbide coatingsfor added abrasion resistance

- Multi-layer designscombining carbonized fiber with ceramic layers

- Smart blanketswith integrated temperature sensors

Carbonized fiber welding blankets represent the gold standard in industrial heat protection. Their unique combination of lightweight flexibility and extreme temperature resistance makes them indispensable for modern metalworking. When selecting yours, prioritize certified products meeting ASTM F955 standards for guaranteed performance.