Biggun Carbon Felt Welding Blanket: Ultimate Heat Protection Solution

The Biggun Carbon Felt Welding Blanket provides superior heat resistance and protection for welding applications. This guide explains its features, benefits, and proper usage to enhance workplace safety and efficiency.

Why Choose Biggun Carbon Felt Welding Blanket?

When you're working with high temperatures, ordinary protective materials won't suffice. The Biggun Carbon Felt Welding Blanket stands out because:

- Withstands temperatures up to 2000°F (1093°C)

- Made from premium carbon felt material for exceptional durability

- Provides excellent thermal insulation properties

- Resists sparks, slag, and molten metal splatter

- Lightweight yet highly protective

Key Applications for Your Welding Blanket

Your Biggun Carbon Felt Welding Blanket serves multiple purposes in industrial settings:

- Welding protection:Shield nearby equipment and surfaces from heat and sparks

- Fire containment:Create safe zones for hot work operations

- Heat treatment:Use as insulation during metal heating processes

- Foundry work:Protect against molten metal spills

- Emergency situations:Quickly smother small fires caused by welding

Proper Usage and Maintenance Tips

To get the most from your Biggun Carbon Felt Welding Blanket:

- Always inspect for damage before use

- Position the blanket to cover all vulnerable areas

- Secure edges with non-flammable weights or clamps

- Allow proper clearance from the heat source (minimum 6 inches recommended)

- Clean with compressed air or a soft brush - never wash with water

- Store flat or rolled in a dry, clean area when not in use

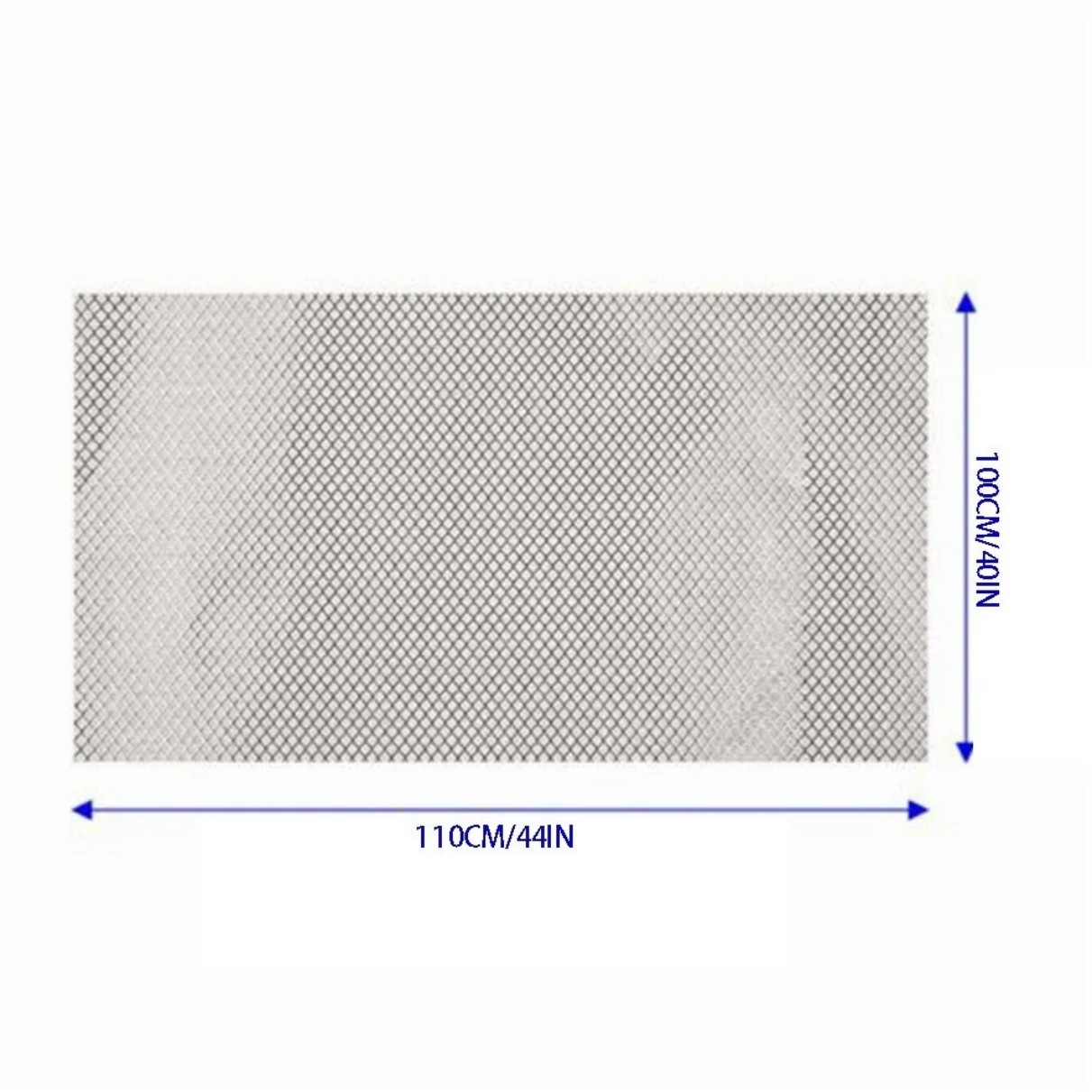

Technical Specifications

Understanding the technical aspects helps you select the right Biggun Carbon Felt Welding Blanket for your needs:

- Material Composition:100% oxidized carbon felt

- Thickness Options:Available in 1/8", 1/4", and 1/2" thicknesses

- Standard Sizes:Ranges from 3' x 3' to 10' x 10'

- Temperature Rating:Continuous use up to 2000°F (1093°C)

- Weight:Approximately 16 oz per square foot (1/4" thickness)

Comparing Carbon Felt to Other Welding Blanket Materials

When you compare the Biggun Carbon Felt Welding Blanket to alternatives, you'll notice significant advantages:

- Versus Fiberglass:Carbon felt offers better heat resistance and doesn't degrade as quickly

- Versus Silica:More flexible and easier to handle while providing similar protection

- Versus Vermiculite:Lighter weight and more durable for repeated use

- Versus Asbestos:Safer alternative with no health risks

Safety Considerations

While your Biggun Carbon Felt Welding Blanket provides excellent protection, remember these safety tips:

- Never use as personal protective equipment - always wear proper PPE

- Monitor for signs of wear or damage during use

- Replace immediately if holes, excessive thinning, or fraying occur

- Keep away from open flames when not in use as a protective barrier

- Ensure proper ventilation when welding near the blanket

Cost-Effectiveness and Longevity

Your investment in a Biggun Carbon Felt Welding Blanket pays off through:

- Extended service life compared to cheaper alternatives

- Reduced replacement costs over time

- Prevention of costly damage to equipment and facilities

- Lower insurance premiums through improved fire safety

- Minimized downtime from heat-related accidents

Where to Purchase and Custom Options

Biggun Carbon Felt Welding Blankets are available through industrial safety suppliers and welding equipment distributors. Many providers offer:

- Custom sizing to fit specific work areas

- Reinforced edges for added durability

- Grommets or hanging hardware for easy installation

- Multi-layer configurations for extreme heat applications

- Bulk purchasing options for large operations

By choosing the right Biggun Carbon Felt Welding Blanket and using it properly, you significantly enhance workplace safety while protecting valuable equipment from heat damage. Its superior performance makes it an essential tool for professional welders and industrial operations.