FM Approved Welding Blankets: Safety & Compliance Guide

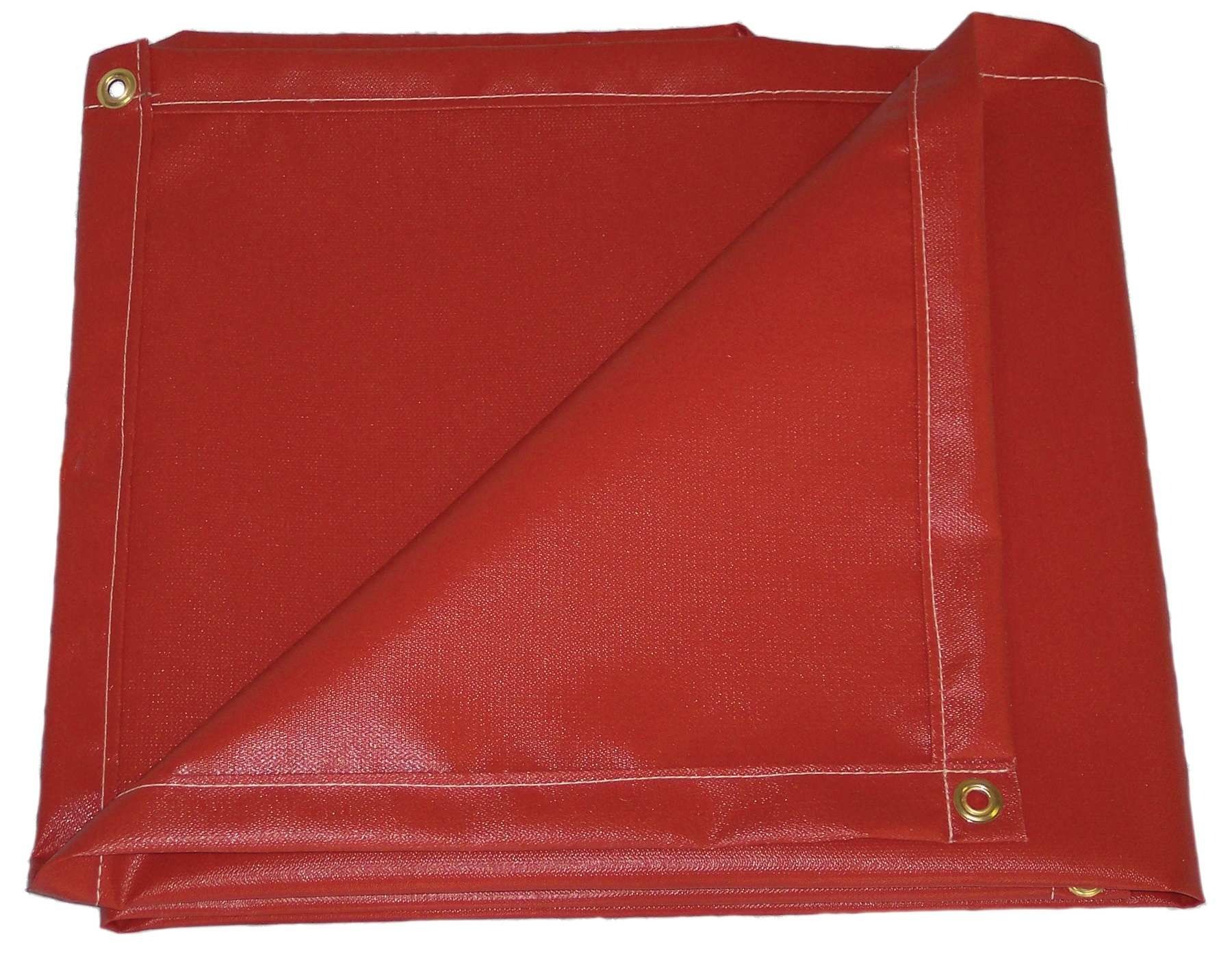

FM Approved welding blankets provide certified protection against sparks and molten metal. This guide explains their safety standards, proper use cases, and how they differ from non-certified alternatives for industrial applications.

What Are FM Approved Welding Blankets?

FM Approved welding blankets are fire-resistant covers that meet strict safety standards set by FM Global, a leading industrial certification organization. Unlike regular welding blankets, these undergo rigorous testing for:

- Flame resistance (must self-extinguish within 2 seconds)

- Heat deflection (withstands temperatures up to 1,800°F/982°C)

- Durability against molten metal splash

Key Benefits of Using FM Approved Blankets

When you choose FM Approved welding blankets, you get:

- Insurance compliance- Many industrial policies require FM Approved equipment

- Predictable performance- Tested under controlled laboratory conditions

- Material integrity- Won't melt or drip when exposed to extreme heat

- Quality assurance- Regular factory audits ensure consistent manufacturing

Common Applications

Use FM Approved welding blankets for:

- Hot work areas in oil refineries

- Shipyard welding operations

- Aerospace manufacturing

- Structural steel fabrication

- Pipeline construction

They're particularly valuable when working near flammable materials or in confined spaces where fire risks are elevated.

How to Select the Right Blanket

Consider these factors when choosing your FM Approved welding blanket:

| Factor | Consideration |

|---|---|

| Size | Measure your work area - common sizes range from 3'x3' to 12'x12' |

| Material | Fiberglass (most common) vs. silica vs. ceramic options |

| Weight | Heavier blankets (16+ oz/sq yd) offer better protection |

| Certification | Look for current FM Approval label with certification number |

Proper Use and Maintenance

To maximize safety and lifespan of your FM Approved welding blanket:

- Inspect for damage before each use

- Keep at least 12 inches away from actual welding arc

- Store flat or rolled - never folded (causes weak points)

- Clean with compressed air, never water or solvents

- Replace when showing significant wear or fiber degradation

FM Approval vs. Other Standards

While FM Approved welding blankets meet the most rigorous industrial standards, you might also encounter:

- OSHA compliant- Meets minimum legal requirements

- UL listed- Safety tested but different criteria

- NFPA 701- Focuses on flame propagation

For high-risk environments, FM Approval provides the highest assurance of performance.

Where to Buy Genuine FM Approved Blankets

Purchase directly from:

- Manufacturers with current FM Global certification

- Industrial safety distributors

- Welding supply specialists

Always verify the FM Approval mark and current certification date. Counterfeit products may look similar but lack proper testing.

Cost Considerations

While FM Approved welding blankets cost 20-40% more than uncertified options, they:

- Reduce insurance premiums in many cases

- Last longer due to higher quality materials

- Prevent costly workplace accidents

For most industrial applications, the investment pays for itself in risk reduction.

When safety matters, FM Approved welding blankets provide certified protection you can trust. Their rigorous testing and quality controls make them the smart choice for professional welding operations.