Waterproof Welding Fire Blanket: Essential Protection for Hot Work

Summary:A waterproof welding fire blanket protects against sparks and molten metal during hot work. This guide explains its features, benefits, proper use, and maintenance to enhance workplace safety.

What Is a Waterproof Welding Fire Blanket?

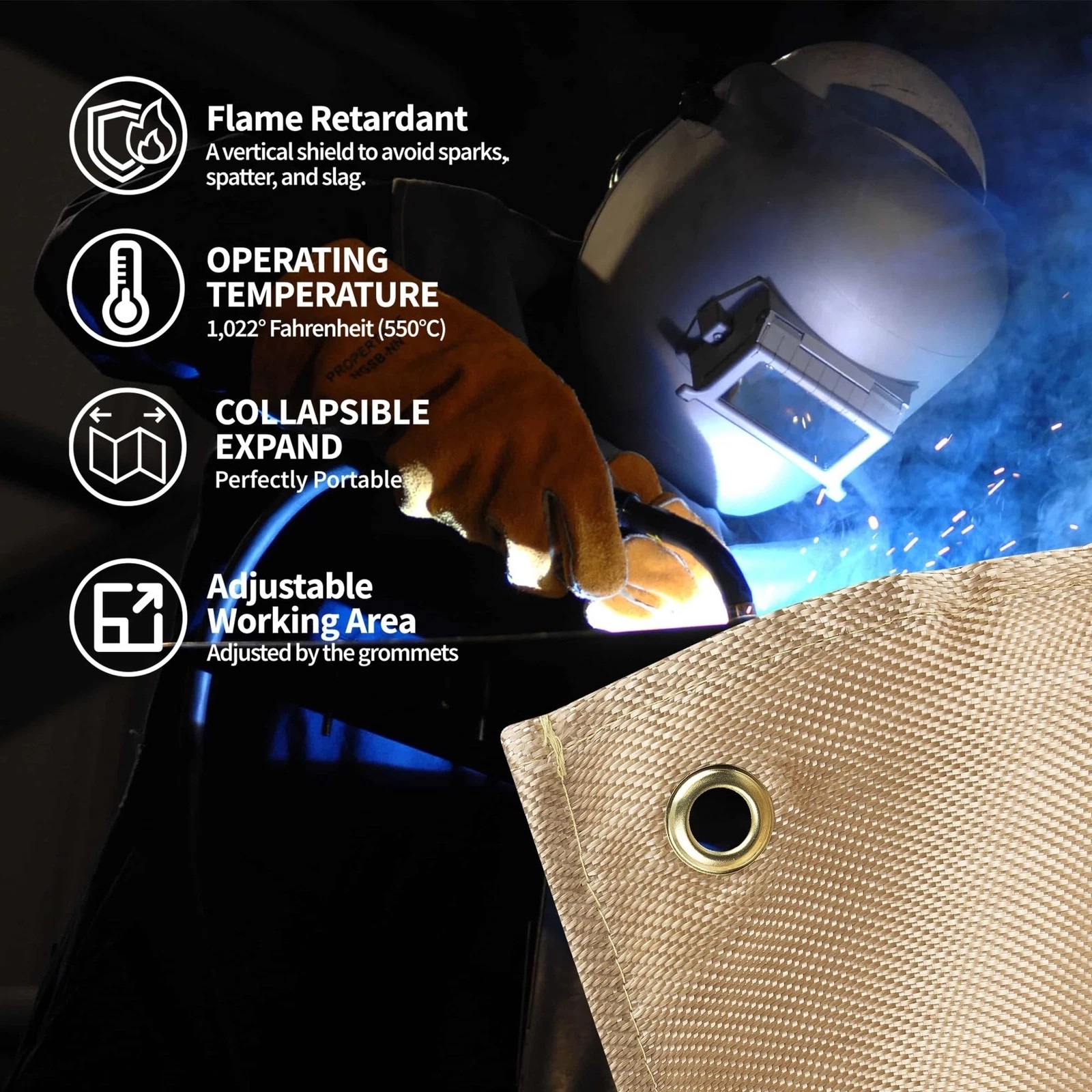

When you're welding, cutting, or grinding, sparks and molten metal can create serious fire hazards. A waterproof welding fire blanket is a specialized safety device designed to contain these risks. Unlike regular fire blankets, it combines flame resistance with waterproof properties for superior protection.

Key Features of Quality Welding Blankets

The best waterproof welding fire blankets share these essential characteristics:

- High-temperature resistance(typically withstands 1000°C/1832°F+)

- Waterproof coatingthat repels liquids without compromising fire resistance

- Flexible yet durableconstruction for easy handling

- Lightweightfor quick deployment

- Chemical-resistantto withstand industrial environments

Why Choose Waterproof Over Standard Welding Blankets?

You might wonder why waterproof matters for welding protection. Consider these advantages:

- Better spark containment:Waterproof surfaces prevent hot particles from sticking

- Easy cleanup:Liquids bead up instead of soaking in

- Longer lifespan:Resists corrosion from moisture exposure

- Versatility:Works equally well in wet or dry conditions

Proper Use of Your Welding Fire Blanket

To maximize protection, follow these steps when using your waterproof welding fire blanket:

- Inspect for damage before each use

- Position to cover all vulnerable surfaces

- Secure edges with weights or clamps

- Overlap multiple blankets for large areas

- Allow complete cooling before handling

Maintenance Tips for Longevity

Your waterproof welding fire blanket requires proper care:

- Clean with mild soap and water only

- Air dry completely before storage

- Store flat or rolled (never folded)

- Keep away from sharp objects

- Replace if coating becomes damaged

Selecting the Right Size and Thickness

Choose based on your specific needs:

| Application | Recommended Size | Thickness |

|---|---|---|

| Small bench work | 3' x 4' | 1-2mm |

| Vehicle welding | 6' x 8' | 2-3mm |

| Industrial sites | 10' x 12' | 3-5mm |

Common Applications Beyond Welding

Your waterproof welding fire blanket has multiple uses:

- Foundry work

- Hot work permits areas

- Emergency fire containment

- Grinding operations

- Furnace maintenance

Safety Standards to Look For

Ensure your blanket meets these certifications:

- EN 1869:1997 (European standard)

- ASTM F1989 (US standard)

- ISO 9001 (Quality management)

- CE marking (EU compliance)

Conclusion

A waterproof welding fire blanket is an essential safety investment for any hot work environment. By choosing the right product and using it properly, you significantly reduce fire risks while protecting both personnel and property. Remember to inspect regularly and replace when needed to maintain optimal protection.