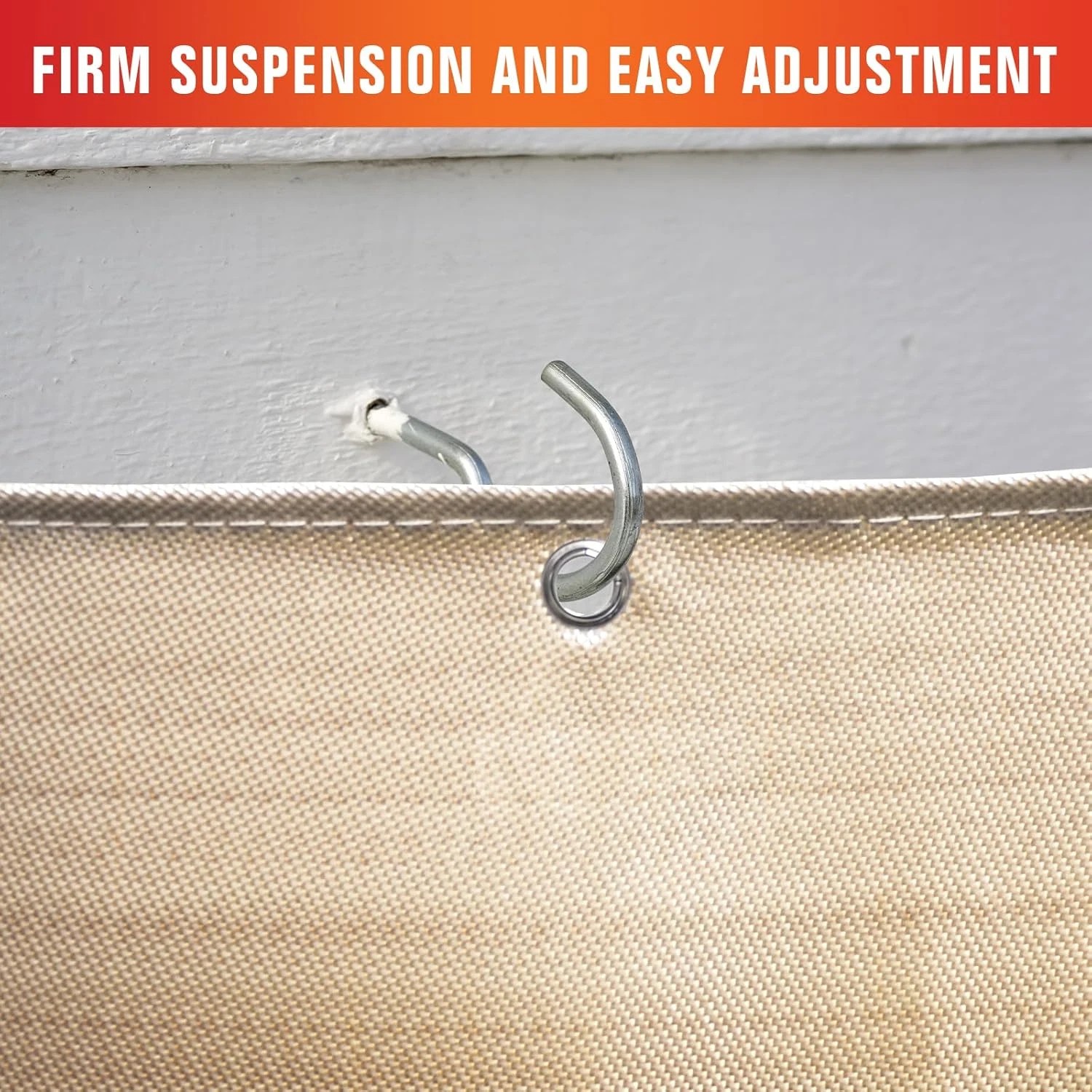

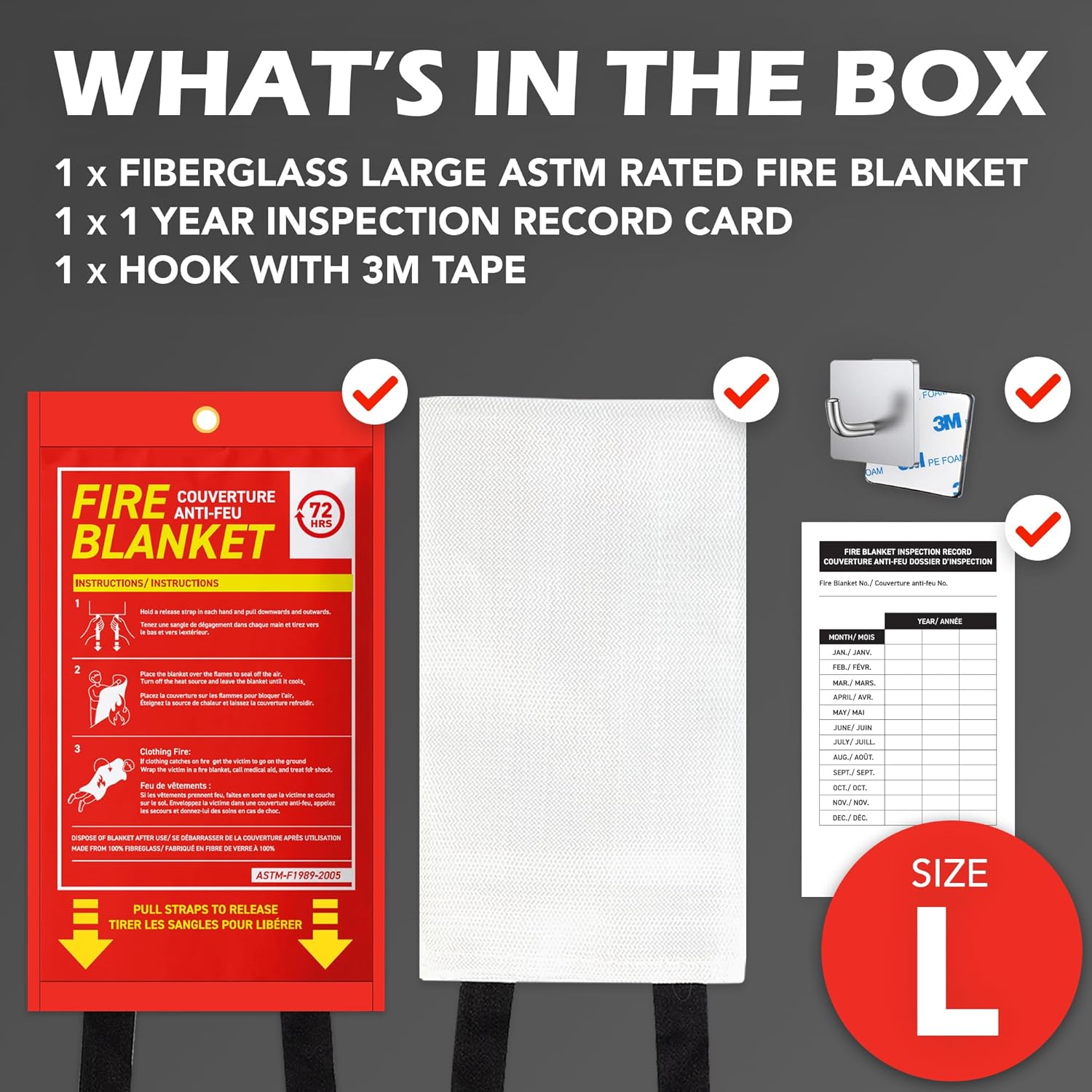

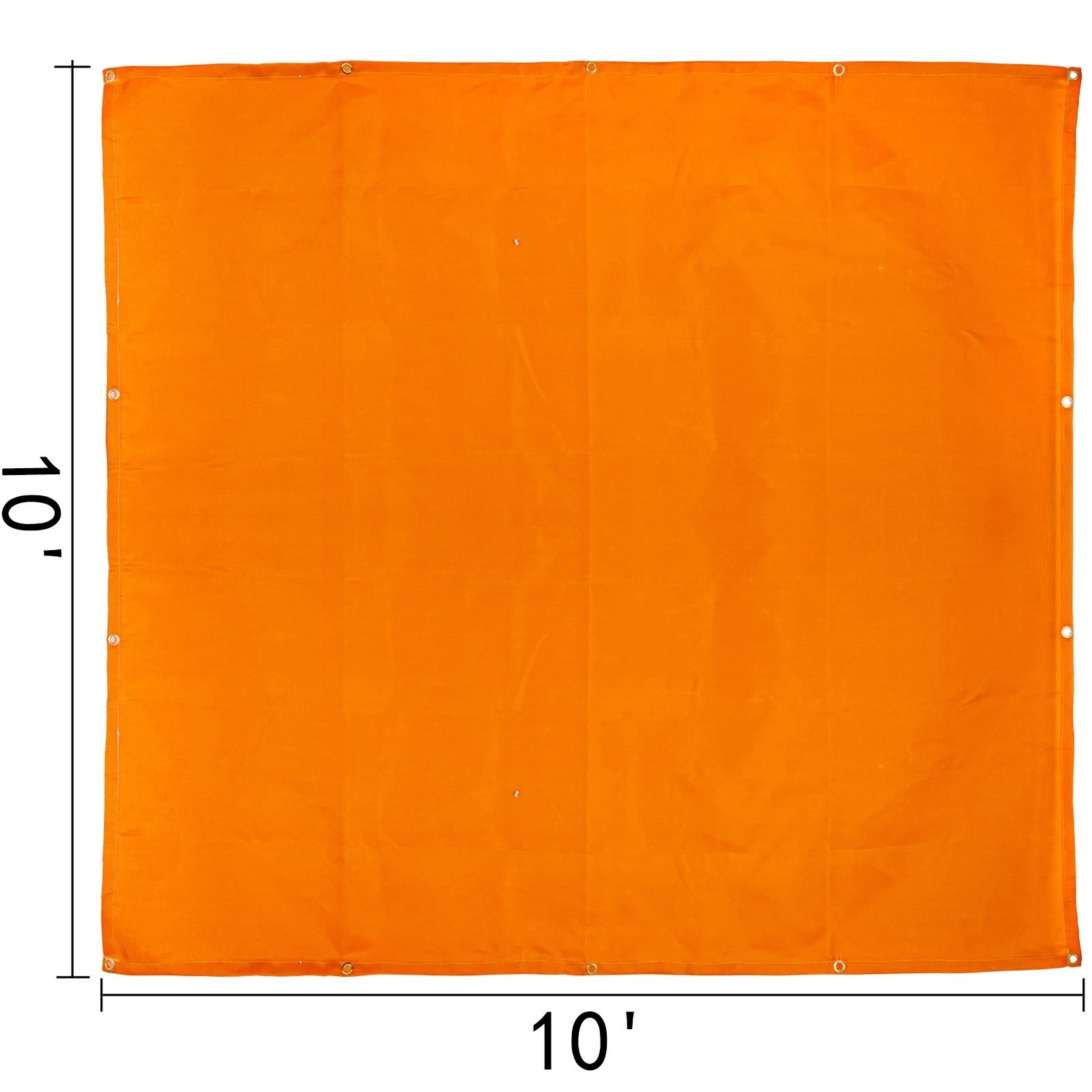

# High-Temp Welding Blankets: Essential Felt Protection for Industrial SafetyThis article explains how felt high temp welding blankets protect workers and equipment from extreme heat and sparks during welding. You'll learn their benefits, materials, uses, and how to choose the right one for your needs.## Why You Need a Felt High Temp Welding BlanketWhen you're welding, cutting, or working with hot materials, sparks and molten metal can cause serious damage. A felt high temp welding blanket acts as your first line of defense. These specialized blankets resist temperatures up to 2000°F (1093°C), protecting nearby surfaces, equipment, and personnel.Unlike regular fabrics, felt high temp welding blankets won't melt or catch fire. Their dense fiber structure absorbs and dissipates heat effectively. You'll find them indispensable in metal fabrication shops, shipyards, construction sites, and any industrial setting where welding occurs.## Key Features of Quality Felt Welding BlanketsThe best felt high temp welding blankets share several important characteristics:1. **Heat resistance**: Look for blankets rated for at least 1800°F (982°C) continuous exposure2. **Durability**: High-quality felt resists tearing and maintains integrity after repeated use3. **Flexibility**: Even when thick, good blankets remain pliable for easy handling4. **Chemical resistance**: Should withstand exposure to oils, solvents, and other workshop chemicals5. **Lightweight**: Heavy blankets become cumbersome during frequent repositioningPremium felt welding blankets often incorporate fiberglass or silica fibers for enhanced protection. Some include reinforced edges or grommets for secure hanging when needed.## Common Applications for Felt High Temp BlanketsYou'll discover numerous uses for these versatile protective covers:- **Welding curtains**: Hang vertically to create safe work zones- **Equipment protection**: Drape over machinery near welding operations- **Floor covers**: Prevent sparks from damaging sensitive surfaces- **Vehicle protection**: Shield trucks or equipment during mobile welding- **Fire barriers**: Contain potential flare-ups in confined spacesConstruction crews particularly value felt high temp welding blankets for protecting finished surfaces during final welding touches on buildings or bridges.## Choosing the Right Felt Welding BlanketConsider these factors when selecting your felt high temp welding blanket:1. **Size requirements**: Measure the area needing coverage with extra margin2. **Temperature rating**: Match to your specific welding processes3. **Thickness**: Thicker blankets (typically 1/8" to 1/4") offer more protection4. **Portability needs**: Foldable designs help when moving between job sites5. **Attachment options**: Grommets or ties provide secure positioningFor most industrial applications, a medium-weight felt blanket around 1/8" thick provides the best balance of protection and handling ease. Always verify the manufacturer's temperature ratings match your intended use.## Proper Care and Maintenance