Fireproof Welding Blankets: Essential Protection for Hot Work Safety

Summary:Fireproof welding blankets protect against sparks, slag, and heat during welding. Made from durable materials like fiberglass or silica, they prevent fires and injuries. Learn how to choose, use, and maintain these essential safety tools.

What Is a Fireproof Welding Blanket?

When you're welding, cutting, or doing any hot work, sparks and molten metal can fly everywhere. A fireproof welding blanket is your first line of defense. These specialized blankets resist extreme heat (typically up to 2000°F/1093°C) and prevent fires by containing sparks and slag.

Why You Need a Quality Welding Blanket Fireproof Solution

Every year, welding accidents cause serious workplace fires. A proper welding blanket fireproof barrier can:

- Protect flammable materials near your work area

- Shield other workers from flying sparks

- Prevent damage to floors, walls, and equipment

- Reduce cleanup time by containing debris

Key Features of Effective Fireproof Welding Blankets

Not all welding covers are equal. Look for these essential features:

- Material:Fiberglass (most common), silica, or ceramic fibers

- Temperature rating:Minimum 1000°F (538°C), ideally 2000°F (1093°C)

- Thickness:1/16" to 1/8" for optimal protection

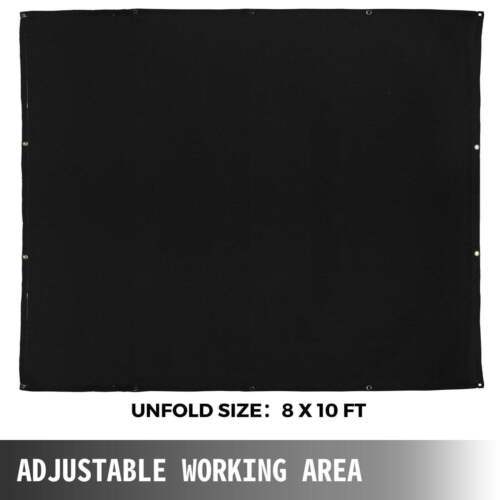

- Size:3'x4' for small jobs up to 12'x12' for large projects

- Edge treatment:Stitched or reinforced edges prevent fraying

How to Properly Use Your Welding Blanket

Simply having a fireproof welding blanket isn't enough - you need to use it correctly:

- Inspect the blanket for damage before each use

- Cover all flammable surfaces within 35 feet of your work area

- Overlap multiple blankets by at least 6 inches if needed

- Secure edges with weights or clamps to prevent movement

- Keep the blanket clean - accumulated debris can reduce effectiveness

Maintenance Tips for Long-Lasting Protection

Your welding blanket fireproof barrier needs proper care:

- Shake out debris after each use

- Wash with mild soap and water when needed (check manufacturer instructions)

- Store flat or rolled - never fold, as this weakens fibers

- Replace if you notice significant wear, holes, or stiffening

Choosing Between Welding Blanket Types

Consider these options based on your needs:

| Type | Best For | Temperature Limit |

|---|---|---|

| Fiberglass | General welding, most cost-effective | 1000-1800°F |

| Silica | High-heat applications, longer lifespan | 2000°F+ |

| Ceramic | Extreme heat, industrial settings | 3000°F+ |

Common Mistakes to Avoid

Even experienced welders sometimes make these errors with fireproof blankets:

- Using damaged blankets (compromises protection)

- Placing blankets directly on hot surfaces (use spacers)

- Assuming one size fits all applications

- Forgetting to protect vertical surfaces too

- Using regular tarps instead of proper welding blanket fireproof materials

Beyond Welding: Other Uses for Fireproof Blankets

These versatile tools also work well for:

- Grinding operations

- Foundry work

- Fireplace protection

- Emergency fire containment

- Hot work in confined spaces

Investing in Safety Pays Off

A quality welding blanket fireproof solution might seem like an extra expense, but it's far cheaper than property damage, medical bills, or lost work time from accidents. Choose the right blanket for your needs, use it properly, and maintain it well - your safety is worth it.