Flame Resistant Welding Blanket: Your Ultimate Protection Guide

Summary:A flame resistant welding blanket protects against sparks, slag and heat during welding. This guide explains its materials, safety standards, proper use cases and maintenance for optimal protection.

What Is a Flame Resistant Welding Blanket?

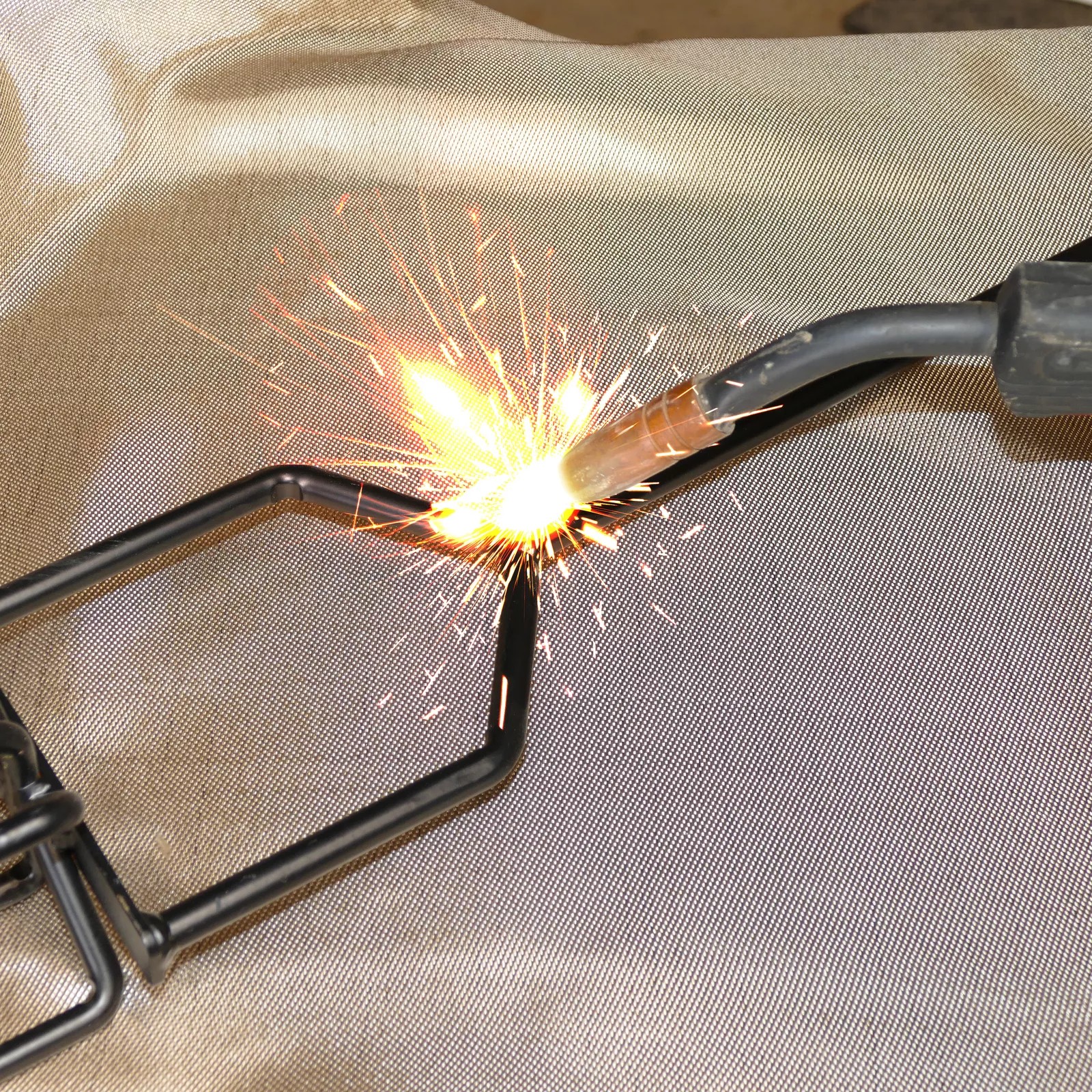

When you're welding, cutting or doing other hot work, sparks and molten metal can fly up to 35 feet. A flame resistant welding blanket acts as a protective barrier between these hazards and flammable materials. Unlike regular tarps, these specialized blankets won't catch fire or melt when exposed to extreme heat.

Key Materials and Construction

Quality flame resistant welding blankets typically use:

- Fiberglass:Most common base material, withstands temperatures up to 1000°F (538°C)

- Silica fabric:For higher heat resistance (up to 1800°F/982°C)

- Vermiculite coating:Adds extra fire protection by expanding when heated

The best blankets have double-stitched edges with high-temp thread to prevent unraveling. Look for thickness between 1/16" to 1/8" - thicker isn't always better as it reduces flexibility.

Safety Standards to Look For

Don't compromise on safety certifications:

- NFPA 2112:Standard on flame-resistant garments

- ASTM F955:Evaluates materials against molten metal splash

- OSHA 1910.252:Welding safety requirements

These certifications ensure your flame resistant welding blanket has been properly tested for real-world conditions.

Proper Usage Scenarios

Use your welding blanket for:

- Covering flammable floors or walls near welding areas

- Protecting vehicles during auto body work

- Creating temporary welding curtains

- Covering valuable equipment near hot work

Avoid using it as personal protective equipment (PPE) - it's designed for area protection, not direct body coverage.

Size and Weight Considerations

Common sizes range from 3'x3' to 12'x12'. Consider:

- Small (3'x3' to 4'x6'):Portable, good for spot protection

- Medium (6'x6' to 8'8'):Most versatile for general use

- Large (10'x10' and up):For covering large equipment

Weight typically ranges from 8-16 oz per square yard. Heavier blankets offer more durability but are harder to handle.

Maintenance and Care Tips

Extend your blanket's lifespan with proper care:

- Shake off slag and debris after each use

- Store folded or rolled in a dry place

- Wash only when necessary with mild soap and water

- Inspect regularly for holes or thinning areas

- Replace if coating becomes brittle or cracks appear

Never use bleach or harsh chemicals that could degrade the flame resistant properties.

Common Mistakes to Avoid

Even with a quality flame resistant welding blanket, errors can compromise safety:

- Using near open flames for extended periods (blankets resist but aren't fireproof)

- Folding while hot - let cool completely first

- Assuming one blanket fits all applications

- Ignoring manufacturer's temperature limits

- Using damaged blankets - small holes can spread quickly

Alternatives and Complementary Protection

While essential, welding blankets work best with other precautions:

- Welding curtains:For larger area containment

- Fire extinguishers:ABC-rated within reach

- Personal PPE:Gloves, jackets and face shields

- Non-flammable backings:Like cement board behind blankets

Remember that no single solution provides complete protection - layers of safety work best.

Choosing the Right Blanket for Your Needs

Ask these questions before purchasing:

- What's the maximum temperature you'll encounter?

- How large an area needs protection?

- Will the blanket need frequent moving/repositioning?

- What certifications does your worksite require?

- Does the manufacturer provide safety data sheets?

Investing in the proper flame resistant welding blanket prevents costly damage and, more importantly, protects lives.