Vermiculite Welding Blanket: Fireproof Protection for Industrial Safety

Summary:Vemiculite welding blankets provide superior heat resistance (up to 2000°F) for welding, foundries, and fire protection. These flexible, non-combustible sheets prevent spatter damage and contain sparks better than fiberglass alternatives while remaining durable through repeated use.

What Is a Vermiculite Welding Blanket?

When you need reliable heat protection, vermiculite welding blankets offer exceptional performance. Made from expanded vermiculite minerals bonded with high-temp adhesives, these 1/4"-thick blankets create an insulating barrier that withstands direct flame contact and molten metal splashes.

Key Advantages Over Other Welding Blankets

Unlike fiberglass or silica fabrics, vermiculite welding blankets won't melt or degrade under extreme heat. You get three critical benefits:

- Higher temperature rating:Protects up to 2000°F (1093°C) versus 1000-1500°F for most alternatives

- Better spark containment:The dense mineral structure stops 98% of welding sparks from escaping

- Longer lifespan:Resists tearing and remains flexible after repeated heating/cooling cycles

Where To Use Vermiculite Welding Blankets

These blankets solve heat protection challenges in multiple industrial scenarios:

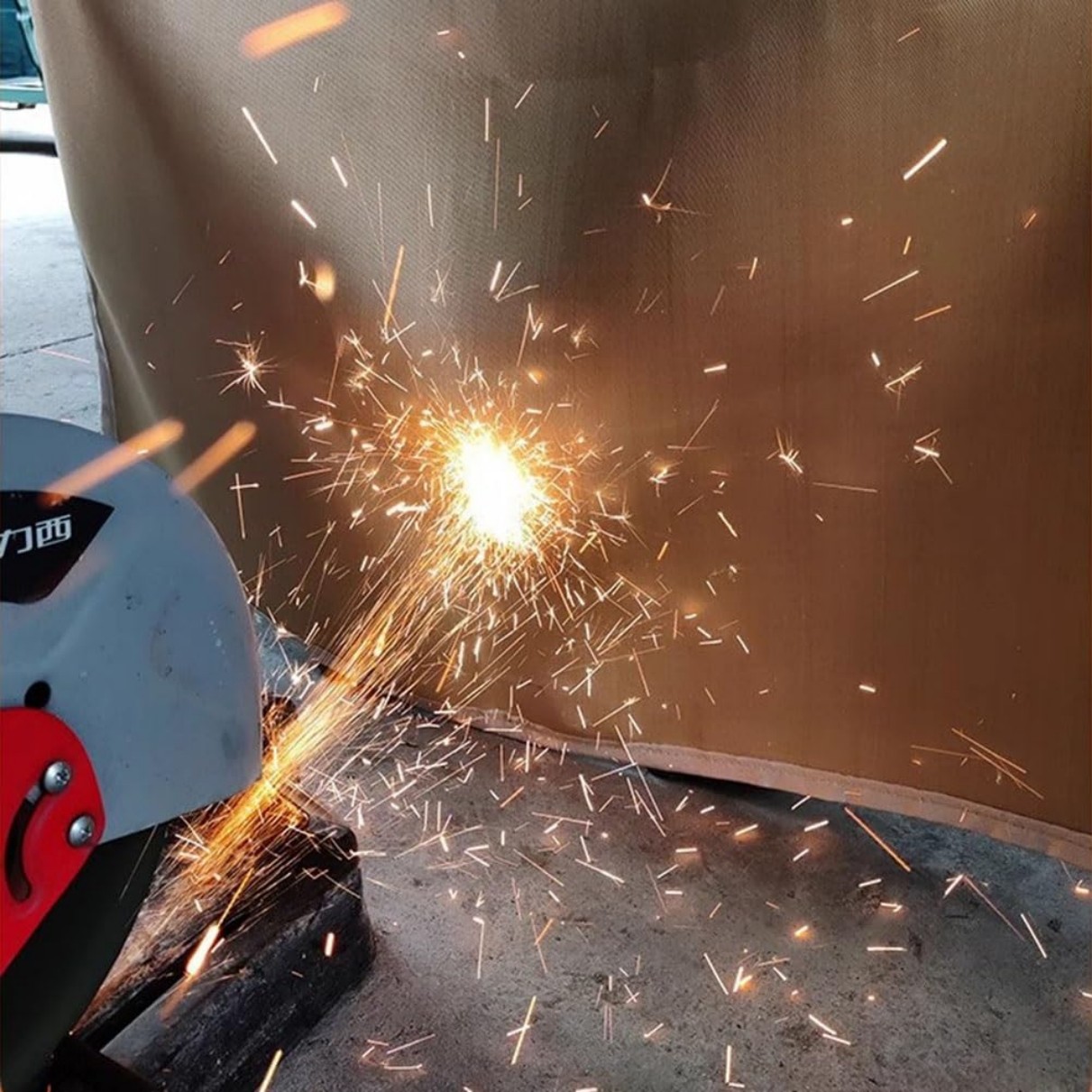

Welding stations:Drape over workbenches or suspend behind welding areas to protect walls from spatter. The blanket's weight (1.5-2 lbs/sq ft) helps it stay in position without additional fasteners.

Pipe welding:Wrap around pipes during welding or cutting to prevent heat damage to nearby components. The material conforms well to curved surfaces.

Emergency fire barriers:Keep folded vermiculite blankets near flammable storage as instant fire curtains. They meet ASTM E84 Class A fire ratings.

Proper Maintenance for Maximum Safety

To ensure your vermiculite welding blanket performs when needed:

- Inspect for cracks or mineral shedding before each use

- Store flat or rolled (never folded) to prevent crease damage

- Clean with compressed air - never wash with liquids

- Replace if the blanket shows >10% thickness reduction

Selecting the Right Size and Thickness

Standard vermiculite welding blankets come in:

| Thickness | Common Sizes | Best For |

|---|---|---|

| 1/4" (6mm) | 3'x4' to 6'x8' | General welding, spark containment |

| 3/8" (10mm) | 4'x6' to 8'x10' | Foundry work, prolonged heat exposure |

For mobile applications, choose lighter 1/4" blankets. Fixed installations benefit from thicker 3/8" versions.

Why Professionals Choose Vermiculite

Industrial safety managers prefer vermiculite welding blankets because they:

- Meet OSHA 1910.252 welding protection standards

- Don't release hazardous fibers like some ceramic blankets

- Maintain flexibility in cold environments (-40°F)

- Can be cut to custom shapes without fraying edges

When comparing costs, remember that while vermiculite welding blankets have higher upfront costs than fiberglass, their 5-7 year service life makes them more economical long-term.