Silica Welding Blanket: Ultimate Protection for High-Temperature Work

Silica welding blankets provide essential protection against sparks, slag, and extreme heat in welding and industrial applications. This guide explains their benefits, uses, and how to choose the right one for your needs.

What Is a Silica Welding Blanket?

A silica welding blanket is a flexible, heat-resistant fabric made from woven silica fibers. These blankets withstand temperatures up to 1800°F (982°C) and protect surfaces from welding sparks, molten metal splatter, and radiant heat. Unlike fiberglass alternatives, silica blankets offer superior thermal protection and durability.

Key Benefits of Using Silica Welding Blankets

- Extreme heat resistance:Withstands continuous exposure to 1800°F and intermittent peaks up to 2000°F

- Non-combustible:Won't catch fire or support flame spread

- Excellent insulation:Reduces heat transfer to protected surfaces

- Chemical resistant:Unaffected by most acids, oils, and solvents

- Flexible and lightweight:Easy to handle and conform to various shapes

Common Applications for Silica Welding Blankets

You'll find silica welding blankets indispensable in these situations:

- Shielding floors, walls, and equipment during welding operations

- Protecting sensitive components in automotive and aerospace manufacturing

- Containing sparks in foundries and metal fabrication shops

- Insulating pipes and valves in high-temperature industrial processes

- Creating temporary heat barriers in construction and demolition projects

How to Choose the Right Silica Welding Blanket

Consider these factors when selecting your blanket:

- Temperature requirements:Match the blanket's rating to your maximum working temperature

- Thickness:Thicker blankets (1/4" to 1/2") offer better insulation but are less flexible

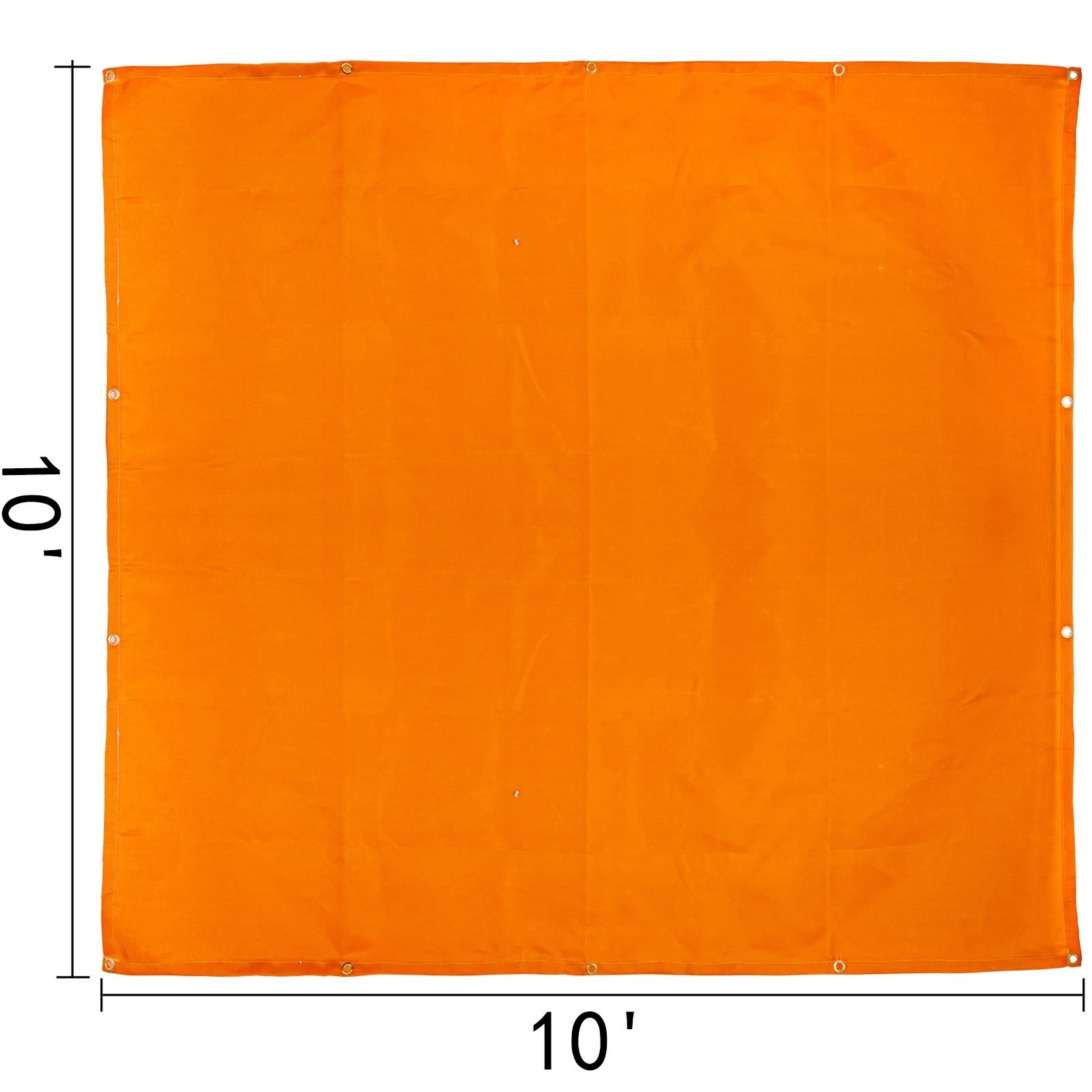

- Size:Measure your work area and add margin for complete coverage

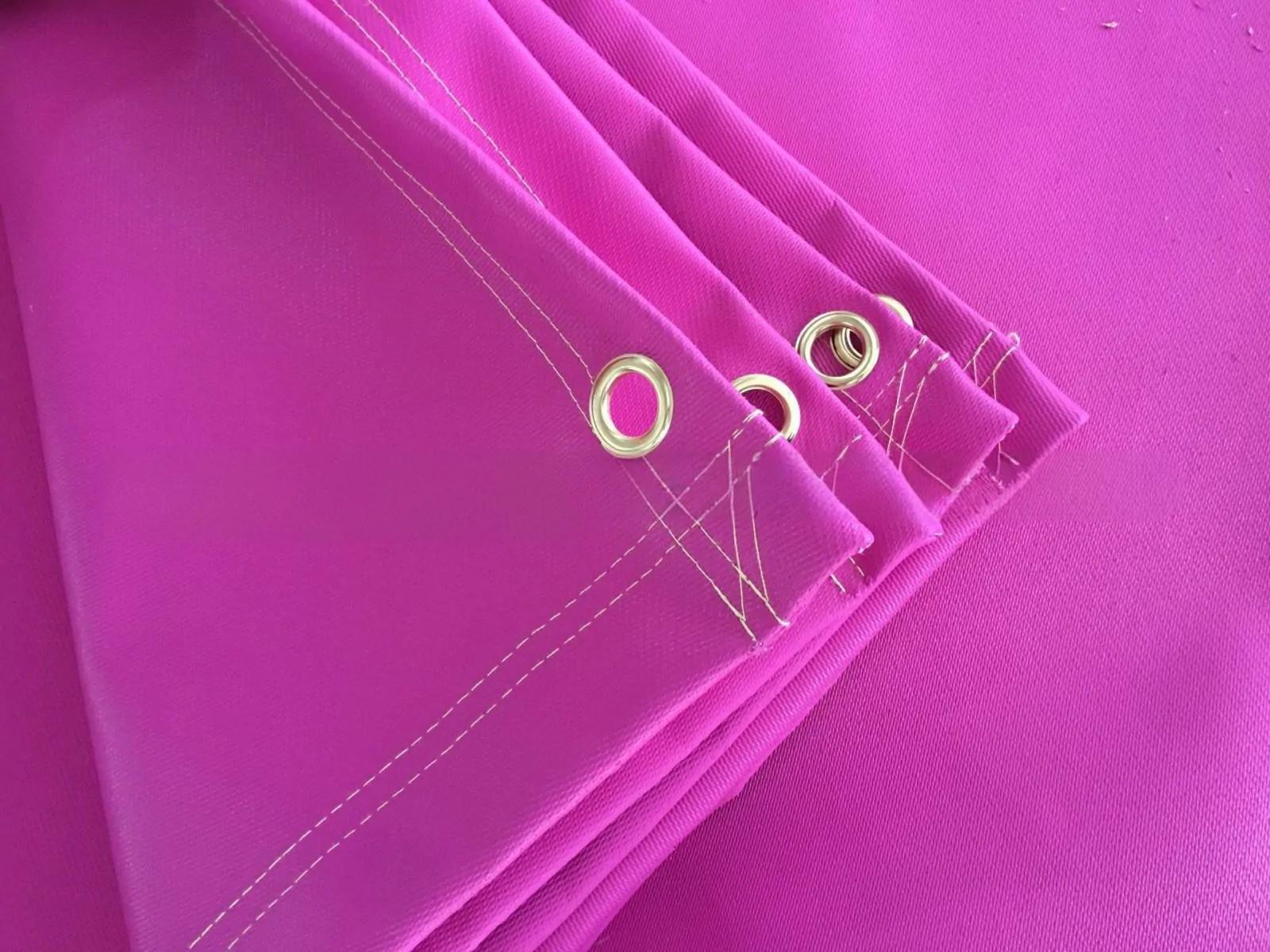

- Reinforcement:Look for stitched edges or wire mesh for tear resistance

- Attachment options:Some blankets include grommets or hooks for secure placement

Proper Use and Maintenance Tips

To maximize your silica welding blanket's lifespan:

- Inspect for damage before each use

- Keep the blanket clean from oil and grease buildup

- Store flat or rolled (not folded) when not in use

- Replace immediately if you notice significant wear or holes

- Use appropriate PPE when handling hot blankets

Silica vs. Fiberglass Welding Blankets

While both materials offer heat protection, silica blankets outperform fiberglass in several ways:

- Higher temperature resistance (1800°F vs. 1000°F for fiberglass)

- Greater durability against abrasion and tearing

- Better resistance to thermal shock

- Longer service life with proper care

However, silica blankets cost more initially. For occasional light-duty use, fiberglass may suffice. For professional or heavy-duty applications, silica is the superior choice.

Safety Considerations

While silica welding blankets provide excellent protection, remember:

- They don't make surfaces completely cool to touch - use caution

- Wear proper protective gear when working near extreme heat

- Ensure proper ventilation when welding under covered areas

- Never use damaged blankets - replace them immediately

Where to Buy Quality Silica Welding Blankets

Purchase from reputable industrial safety suppliers or welding equipment specialists. Look for products that meet relevant safety standards like OSHA and NFPA. Many manufacturers offer custom sizes if standard dimensions don't fit your needs.

By investing in a high-quality silica welding blanket and using it properly, you'll significantly improve workplace safety and protect valuable equipment from heat damage. The initial cost pays for itself through reduced equipment replacement and improved fire safety.