Fire Blanket Welding: Safety Tips and Best Practices for Welders

This guide explains how fire blankets enhance welding safety by preventing fire hazards. You'll learn proper usage, material selection, and maintenance tips to protect yourself and your workspace during welding operations.

Why Fire Blanket Welding Safety Matters

When you weld, sparks and molten metal can travel several feet, potentially igniting flammable materials. A fire blanket creates a protective barrier that smothers sparks and small fires instantly. Unlike traditional methods, fire blanket welding protection is reusable, cost-effective, and doesn't leave residue.

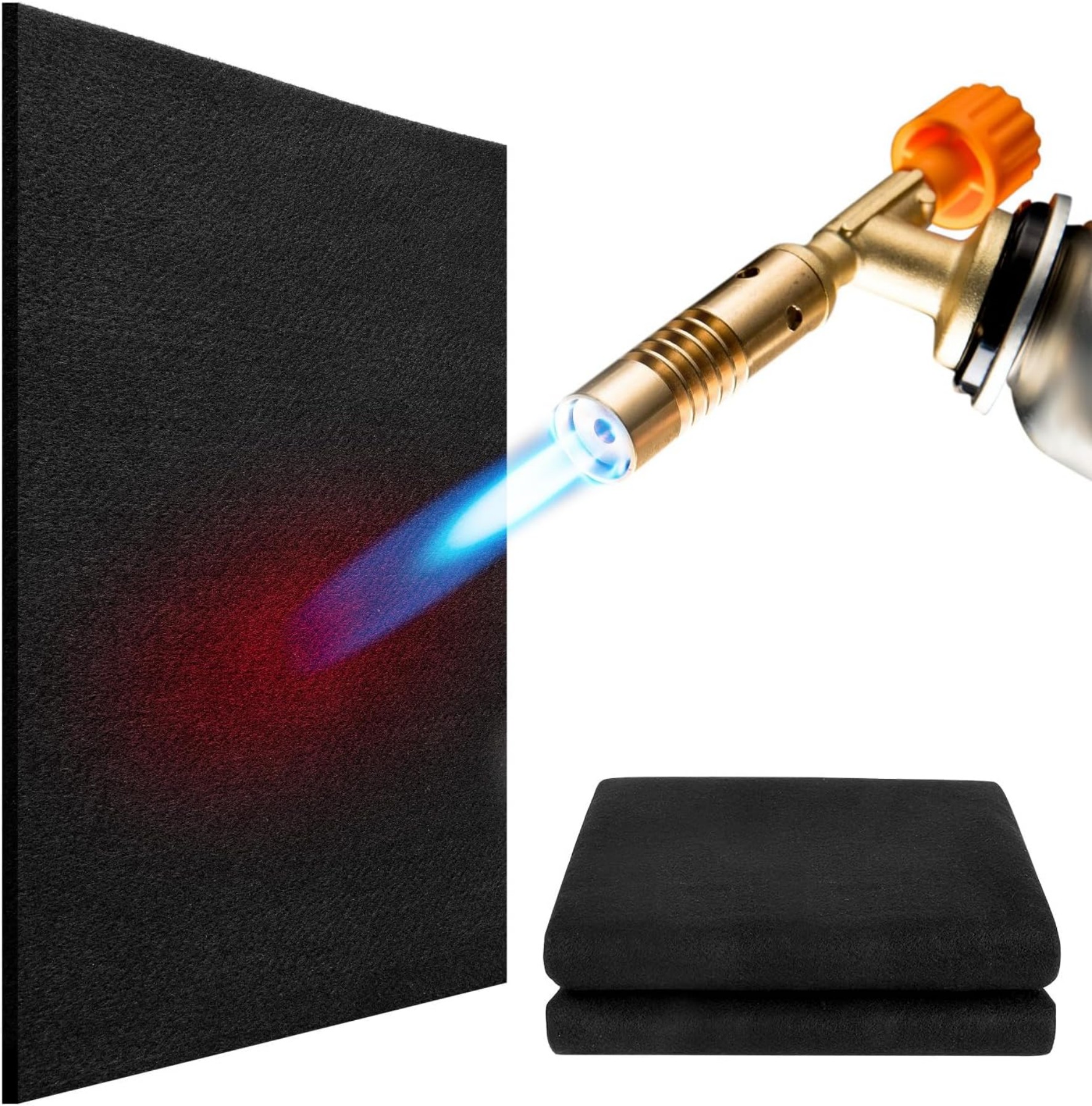

Choosing the Right Fire Blanket for Welding

Not all fire blankets work equally well for welding. You need one made from fiberglass or other high-temperature resistant materials (typically rated above 1000°F/538°C). Look for blankets with silicone coatings for extra durability. The size should cover at least 1.5 times your work area.

Proper Placement of Welding Fire Blankets

Position your fire blanket within arm's reach but away from direct sparks. Drape it over nearby flammable objects or use it to create a protective wall. For vertical surfaces, secure the blanket with non-flammable clips. Remember to overlap multiple blankets by at least 6 inches if covering large areas.

Using Fire Blankets During Welding Operations

Before starting, inspect your fire blanket for damage. During welding, immediately cover any small fires with the blanket, pressing down to cut off oxygen. For clothing fires, wrap the person tightly in the blanket and roll them. Never use water on electrical or grease fires near welding equipment.

Maintenance and Care of Welding Fire Blankets

After use, shake out debris gently - don't wash unless specified by the manufacturer. Store in a dry, accessible location away from chemicals. Replace blankets with holes, frayed edges, or stiff spots. Most quality welding fire blankets last 3-5 years with proper care.

Fire Blanket Welding vs. Other Protection Methods

Compared to fire extinguishers, blankets don't require cleanup and work instantly. Unlike welding curtains, they provide physical barriers against sparks. Combine fire blanket welding with other safety measures like proper ventilation and PPE for maximum protection.

Common Mistakes to Avoid

Don't use wool or cotton blankets as substitutes - they can burn. Never leave blankets touching hot metal after welding. Avoid folding them too tightly, which can damage fibers. Most importantly, don't rely solely on fire blankets - maintain all standard welding safety protocols.

Emergency Procedures with Fire Blankets

If a fire starts, remember PASS: Pull the blanket, Approach carefully, Smother the flames, Stay until cool. For larger fires, evacuate immediately and call emergency services. Always have an escape route when using fire blanket welding protection.

Training Your Team

Conduct regular drills showing proper fire blanket deployment. Demonstrate how to inspect and maintain them. Post clear instructions near welding stations. Ensure everyone understands that fire blanket welding safety is part of your overall hazard prevention plan.

Where to Purchase Quality Welding Fire Blankets

Buy from reputable safety equipment suppliers that specify welding applications. Check for certifications like NFPA 701 or EN 1869. Industrial-grade blankets typically cost $50-$200 depending on size and rating. Consider having multiple blankets for different work areas.