Welding Heat Blankets: Essential Protection for High-Temperature Applications

Summary:Welding heat blankets protect surfaces from sparks, slag, and radiant heat during welding. These flame-resistant covers prevent fire hazards and material damage while being durable and easy to use.

What Is a Welding Heat Blanket?

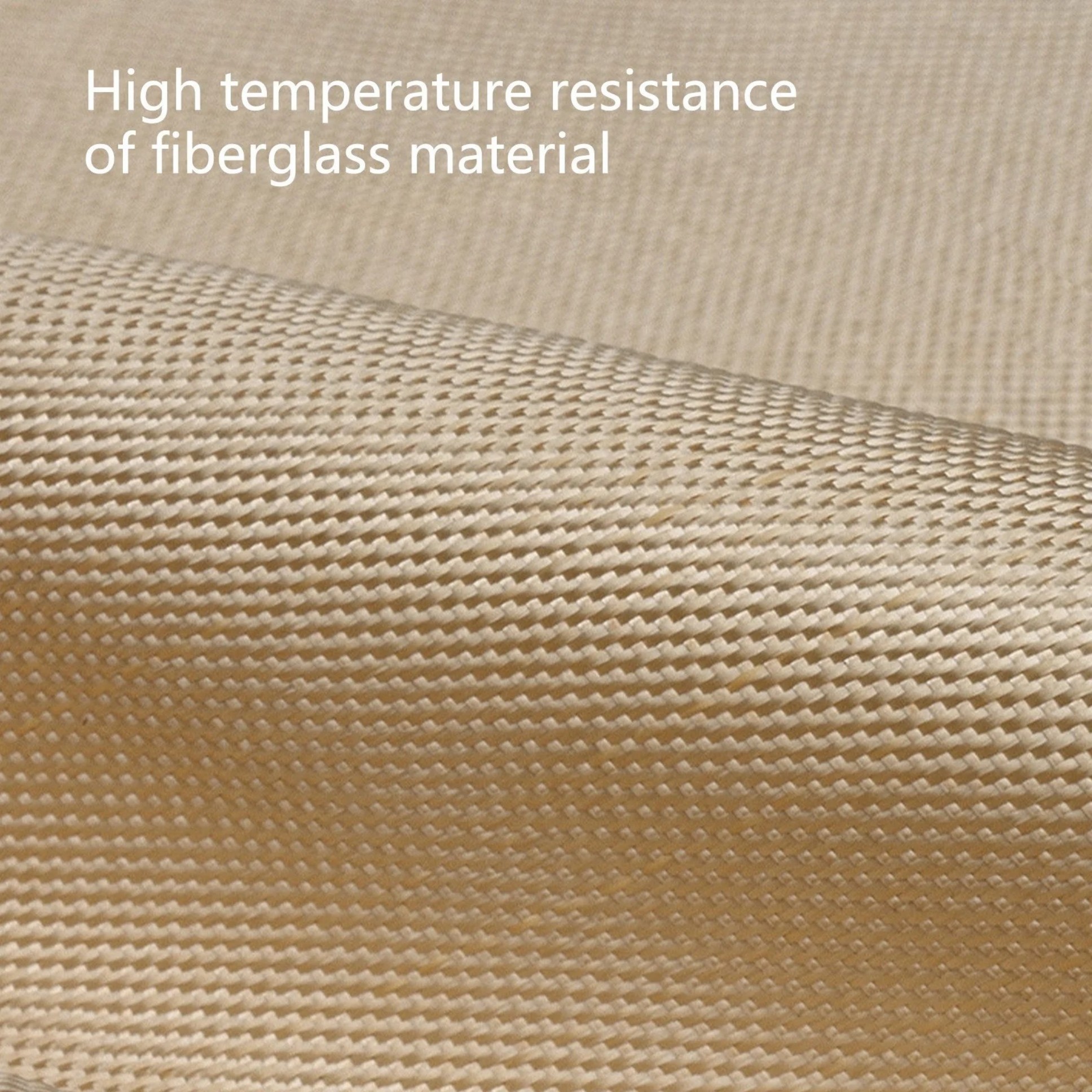

When you're welding, sparks and molten metal can damage nearby surfaces. A welding heat blanket solves this problem. These specialized covers are made from flame-resistant materials like fiberglass or silica fabric. They withstand temperatures up to 2000°F (1093°C) while protecting floors, walls, and equipment.

Key Benefits of Using Welding Heat Blankets

You'll appreciate these advantages when using quality welding heat blankets:

- Fire prevention:Stops sparks from igniting flammable materials

- Surface protection:Prevents burn marks on floors and walls

- Reusable:Unlike disposable alternatives, these last for years

- Flexible:Conforms to irregular surfaces and tight spaces

- Easy cleanup:Molten metal slides off instead of sticking

How to Choose the Right Welding Heat Blanket

Selecting the proper welding heat blanket depends on your specific needs:

Material:Fiberglass offers basic protection, while silica fabrics handle extreme temperatures. For chemical resistance, consider ceramic fiber blankets.

Thickness:Thicker blankets (1/4" or more) provide better insulation but are less flexible.

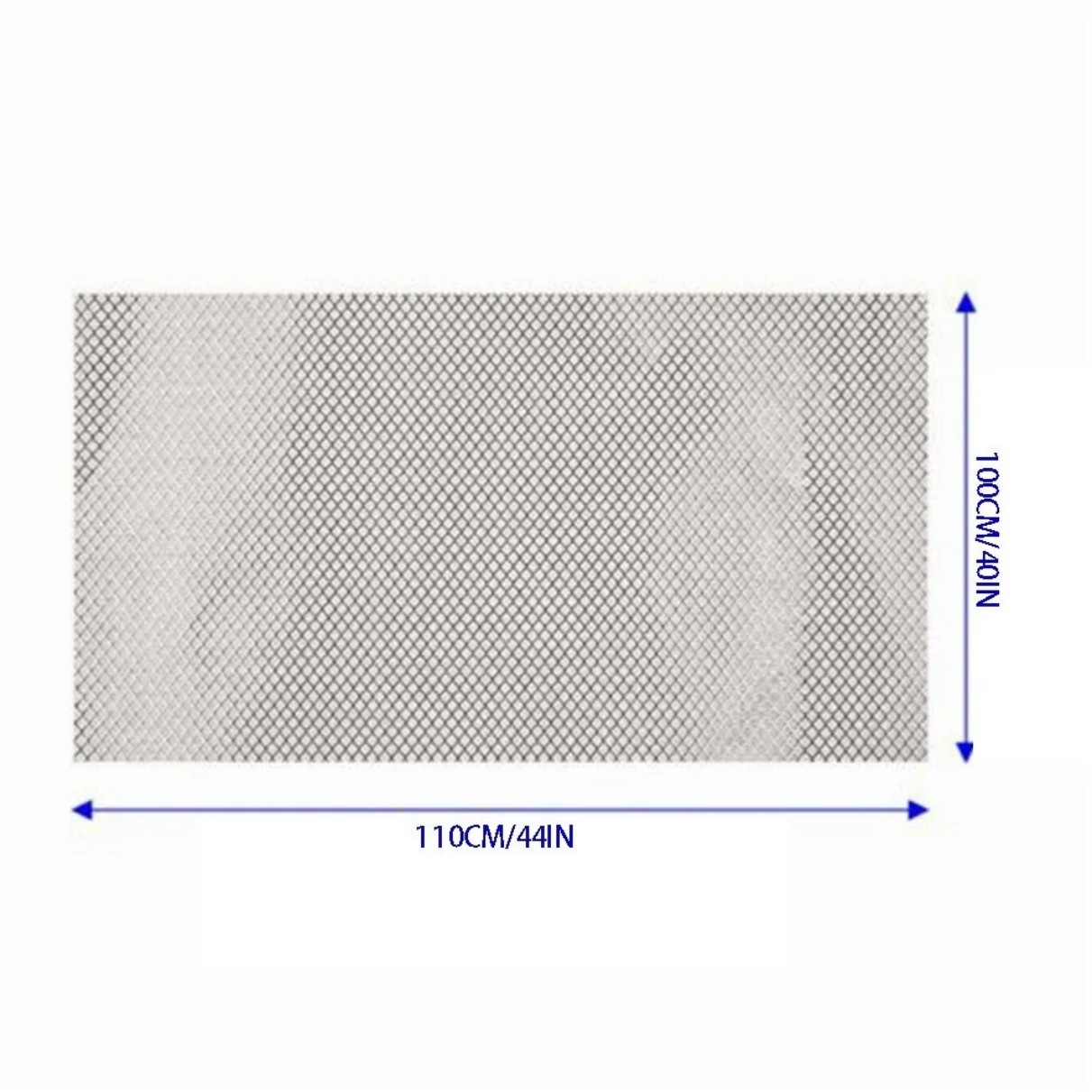

Size:Measure your work area and add 12-18 inches of overlap on all sides.

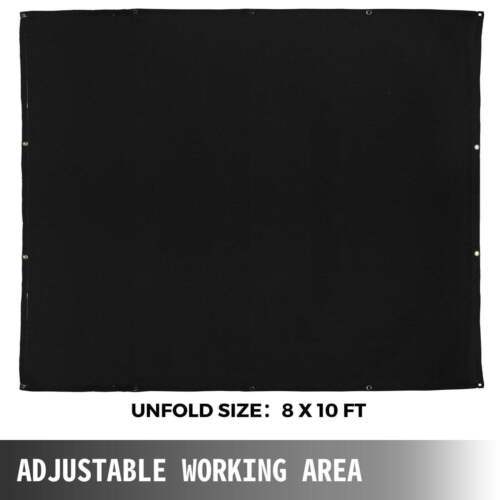

Attachment:Some models include grommets for securing with hooks, while others use Velcro straps.

Proper Use and Maintenance

To get the most from your welding heat blanket:

- Inspect for damage before each use

- Secure all edges to prevent lifting

- Keep away from sharp objects that could puncture the material

- Shake off debris rather than brushing (to prevent fiber damage)

- Store flat or rolled - never folded - to prevent crease damage

Common Applications Beyond Welding

While designed for welding, these versatile blankets also protect during:

- Metal grinding operations

- Foundry work

- High-temperature pipe wrapping

- Fire curtain applications

- Thermal insulation projects

Safety Considerations

Remember these safety tips when using welding heat blankets:

Never use damaged blankets - small holes can allow sparks through. Always wear proper PPE (gloves, eye protection) when handling hot blankets. Allow sufficient cooling time before moving or storing. Keep a fire extinguisher nearby as an additional precaution.

Comparing to Alternatives

Welding heat blankets outperform other protection methods:

Versus metal shields:Blankets are lighter, more flexible, and don't conduct heat to surrounding areas.

Versus fire extinguishers:Prevention is better than reaction - blankets stop fires before they start.

Versus wetting surfaces:Water evaporates quickly and can create steam hazards near hot work.

Conclusion

A quality welding heat blanket is one of the smartest investments you can make for shop safety. By choosing the right type and using it properly, you'll protect both your workspace and your workers from welding hazards. These durable, reusable covers pay for themselves by preventing costly damage and downtime.