Essential Welding Blanket for Plumbing: Safety & Efficiency Guide

This guide explains how welding blankets protect plumbing systems during repairs. You'll learn about material choices, proper usage techniques, and safety benefits when working with pipes and fixtures.

Why You Need a Welding Blanket for Plumbing Work

When repairing or installing plumbing systems, sparks and heat from welding can damage nearby pipes, walls, or flooring. A welding blanket for plumbing creates a protective barrier that:

- Prevents accidental fires from sparks (melting point typically exceeds 1,800°F)

- Protects finished surfaces from heat discoloration

- Contains molten metal splatter during pipe welding

- Shields adjacent plastic pipes from radiant heat

Choosing the Right Welding Blanket for Plumbing Applications

Not all welding blankets work equally well for plumbing jobs. Consider these factors:

Material Types

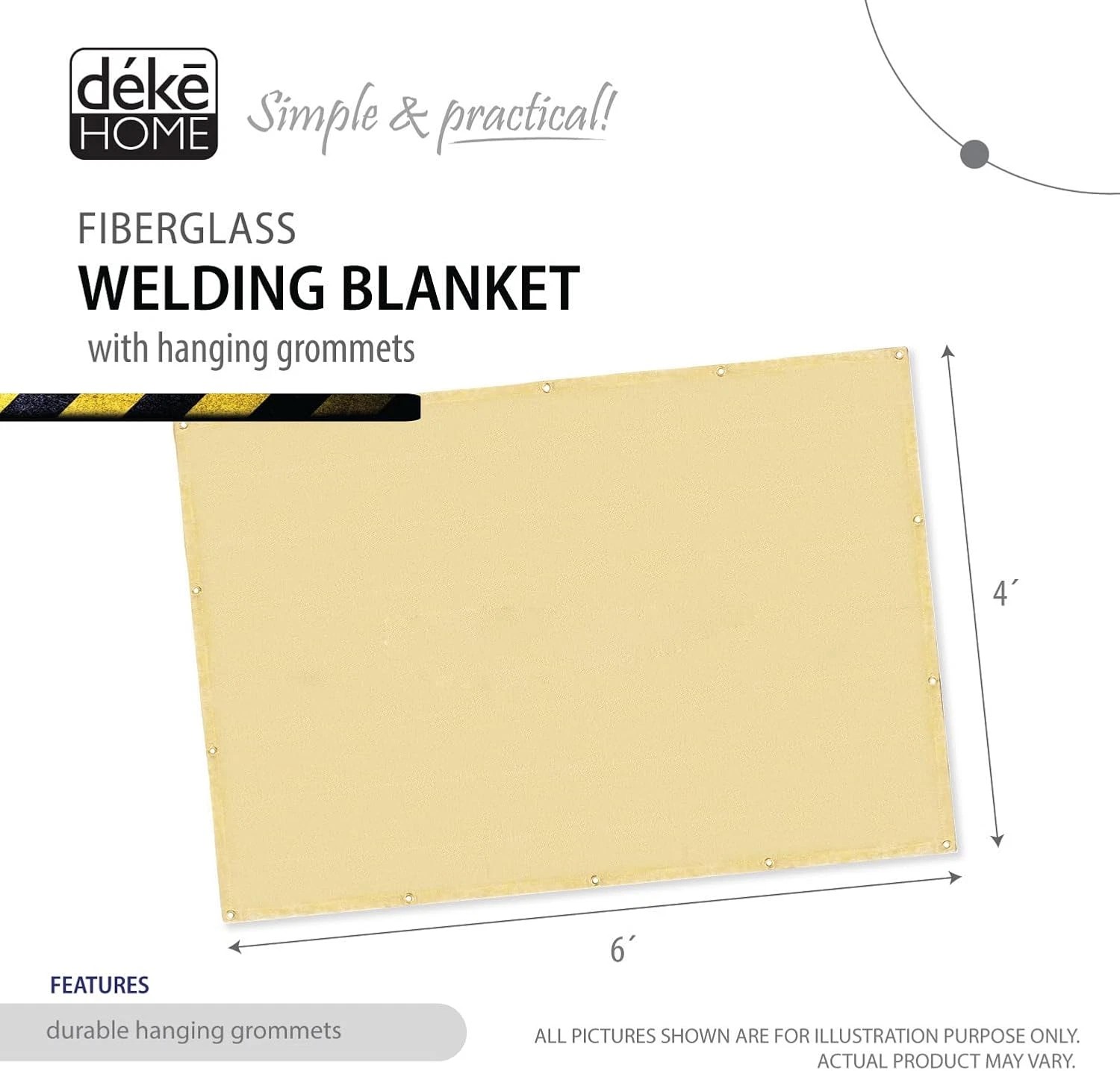

Fiberglass:Most common for plumbing, withstands 1,000-1,800°F. Look for silicone-coated versions for extra durability.

Carbon Fiber:Higher heat resistance (up to 3,000°F) for commercial plumbing systems.

Leather:Best for protecting finished surfaces during small repairs.

Size Considerations

Standard sizes (3'x3' to 6'x8') work for most residential jobs. Measure your work area and add 12" clearance on all sides.

Proper Use of Welding Blankets in Plumbing

Maximize safety and effectiveness with these professional techniques:

- Inspect for tears or damage before each use

- Secure edges with magnetic hooks or welding clamps

- Layer two blankets for critical areas near plastic pipes

- Keep a fire extinguisher rated for electrical/chemical fires nearby

Special Plumbing Scenarios

Working Near PVC Pipes

PVC begins softening at 140°F. Use a welding blanket for plumbing with aluminum foil backing when working within 3 feet of plastic pipes.

Overhead Pipe Welding

For ceiling pipes, choose a blanket with grommets for secure hanging. The 4'x6' size offers best maneuverability.

Maintenance Tips

Extend your welding blanket's lifespan:

- Shake out debris after each use

- Hand wash with mild detergent (never machine wash)

- Store flat or rolled - never folded

- Replace when fibers become brittle or coating flakes

Common Plumbing Welding Mistakes to Avoid

Even with a welding blanket for plumbing, these errors cause problems:

- Using blankets with chemical treatments near drinking water pipes

- Ignoring manufacturer's temperature ratings

- Covering ventilation openings during soldering

- Reusing blankets with metal splatter embedded in fibers

Professional Alternatives

For large commercial plumbing projects, consider:

- Modular welding curtain systems

- Custom-fitted pipe insulation jackets

- Heat-resistant epoxy coatings for permanent protection

A quality welding blanket for plumbing pays for itself by preventing costly damage. Choose the right protection for your specific job, and you'll work safer while protecting the building's plumbing infrastructure.