High Temp Felt Welding Blanket: Ultimate Heat Protection Solution

Summary:High temp felt welding blankets provide superior heat protection for welding, foundries, and industrial applications. These durable, flame-resistant barriers withstand extreme temperatures while protecting workers and equipment.

What is a High Temp Felt Welding Blanket?

When you're working with intense heat from welding, cutting, or grinding, a high temp felt welding blanket becomes your first line of defense. These specialized blankets are made from heat-resistant materials like fiberglass or silica fabrics, often with a felt-like texture for added durability.

Key Features and Benefits

High temp felt welding blankets offer several advantages that make them essential for industrial settings:

- Extreme heat resistance:Withstands temperatures up to 2000°F (1093°C)

- Flame retardant:Won't catch fire or contribute to flame spread

- Durable construction:Resists tears, sparks, and molten metal splatter

- Flexible protection:Can be draped over irregular shapes and surfaces

- Reusable:Unlike disposable alternatives, these blankets last for years

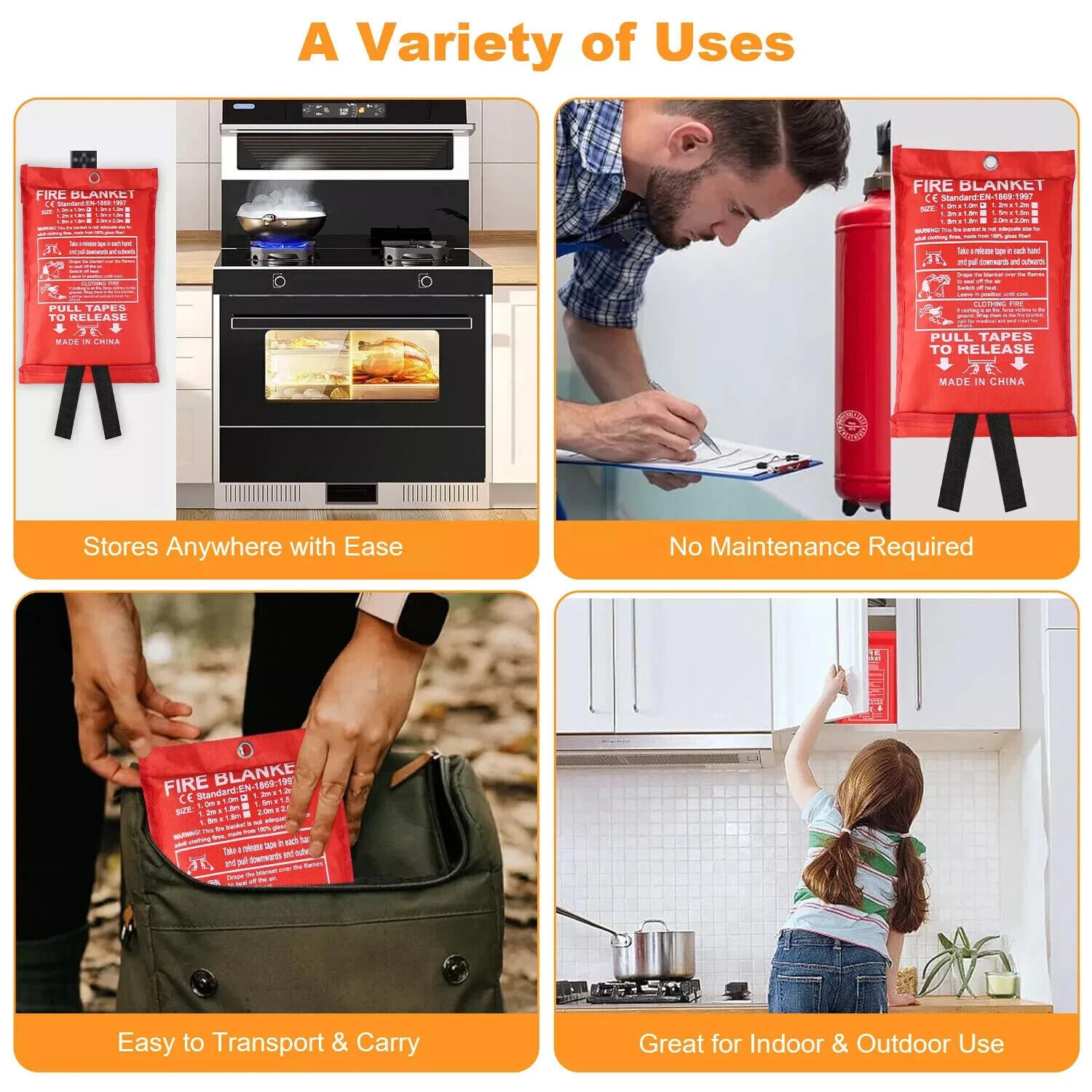

Common Applications

You'll find high temp felt welding blankets used in various industrial scenarios:

Welding operations:Protect nearby equipment, walls, and flooring from sparks and heat damage during arc welding, MIG welding, or TIG welding processes.

Foundry work:Shield workers from molten metal splashes during pouring operations.

Pipeline maintenance:Contain heat during pipeline repairs and hot work permits.

Aerospace manufacturing:Protect sensitive components during high-temperature processes.

Choosing the Right High Temp Felt Welding Blanket

When selecting a welding blanket, consider these factors:

- Temperature rating:Match the blanket's maximum temperature to your application needs.

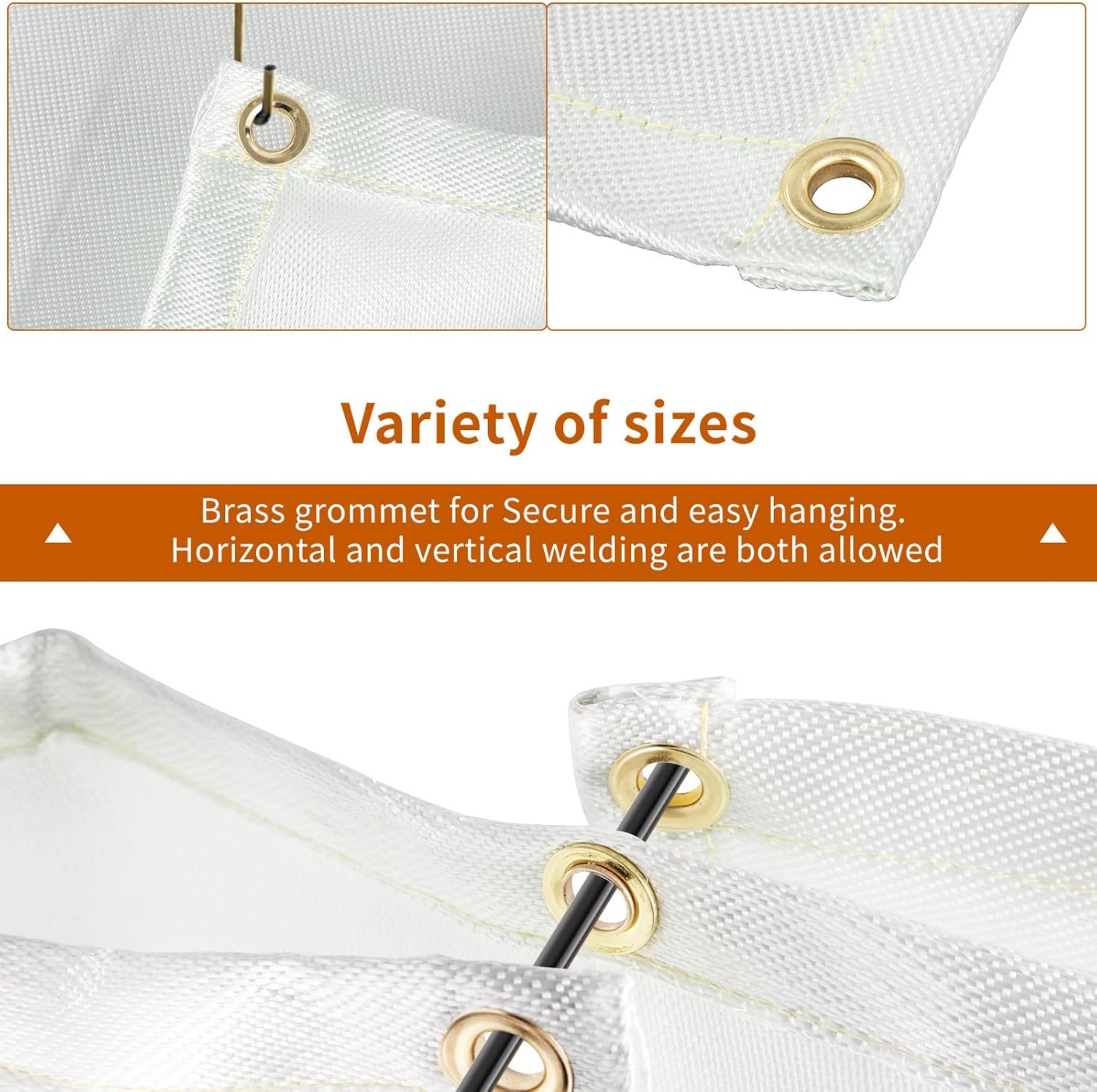

- Size and thickness:Larger, thicker blankets offer more protection but may be less flexible.

- Material composition:Fiberglass is common, but silica fabrics offer higher temperature resistance.

- Edge treatment:Look for reinforced edges with grommets for hanging when needed.

- Certifications:Ensure the blanket meets relevant safety standards for your industry.

Proper Use and Maintenance

To get the most from your high temp felt welding blanket:

Always inspect the blanket before use for any tears or damage. Position it to completely cover vulnerable areas, overlapping sections if necessary for complete protection. After use, allow the blanket to cool completely before storage.

For cleaning, gently shake off debris or use compressed air. Avoid harsh chemicals that could degrade the heat-resistant properties. Store the blanket flat or rolled in a dry, clean area away from direct sunlight.

Safety Considerations

While high temp felt welding blankets provide excellent protection, remember they're just one part of your safety system:

- Always wear appropriate PPE (personal protective equipment) when working with high temperatures

- Never leave hot work unattended, even with blanket protection

- Monitor blankets for signs of wear that could compromise protection

- Have fire extinguishers readily available in your work area

Comparing to Other Heat Protection Methods

High temp felt welding blankets offer advantages over alternatives:

Versus metal shields:Blankets are lighter, more flexible, and don't conduct heat like metal.

Versus disposable covers:Felt blankets are more economical long-term and environmentally friendly.

Versus ceramic fiber:Felt blankets are generally more durable and easier to handle.

Innovations in Welding Blanket Technology

Recent advancements in high temp felt welding blankets include:

Multi-layer constructions that combine different materials for optimal performance. Some newer blankets incorporate reflective surfaces to redirect radiant heat. Others feature quick-release fasteners for rapid deployment in emergency situations.

Conclusion

A high temp felt welding blanket is an essential safety tool for any operation involving extreme heat. By choosing the right blanket and using it properly, you can significantly reduce fire risks and protect both personnel and equipment. Invest in quality protection that matches your specific thermal challenges.