Northern Tool Welding Blanket Guide: Safety & Usage Tips

Northern Tool welding blankets protect against sparks, heat, and molten metal. This guide explains their features, proper use, maintenance, and how they compare to other brands. You'll learn to choose the right blanket for your welding projects.

What Makes Northern Tool Welding Blankets Special

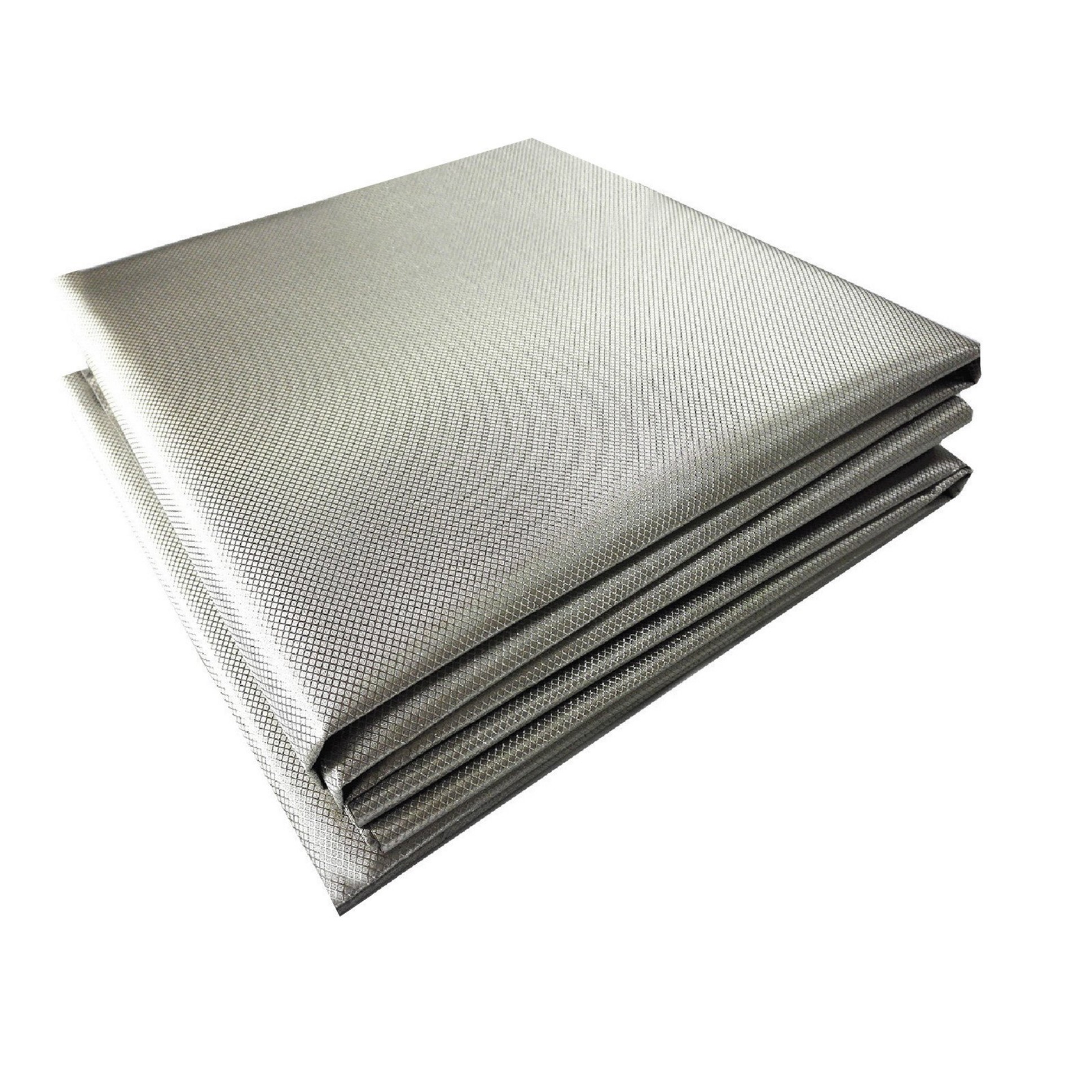

Northern Tool welding blankets stand out for their durable fiberglass construction with silicone coating. They resist temperatures up to 1,800°F (982°C), making them ideal for most welding applications. The reinforced edges prevent fraying, while the flexible material allows easy positioning around work areas.

Key Features to Look For

When selecting a Northern Tool welding blanket, consider these factors:

Size:Available in multiple dimensions (common sizes: 4'x6', 6'x8', 8'8') to fit different workspaces.

Thickness:Thicker blankets (typically 1/8" or 1/4") offer better protection against intense heat.

Color:Northern Tool offers various colors (silver, black) for different heat resistance levels.

Grommets:Some models include metal grommets for hanging or securing the blanket.

Proper Usage Techniques

To get maximum protection from your Northern Tool welding blanket:

1. Cover all nearby flammable surfaces completely - don't leave gaps.

2. Position the blanket at least 12 inches from the welding area when possible.

3. Use multiple blankets for large projects or overlap them carefully.

4. Secure the blanket with weights or clamps to prevent movement during work.

5. Inspect for damage before each use - replace if you find holes or thin spots.

Maintenance and Care

Northern Tool welding blankets require simple maintenance:

Cleaning:Shake off debris after use. For stubborn dirt, use compressed air or a soft brush. Never machine wash.

Storage:Fold neatly and store in a dry place away from direct sunlight when not in use.

Repairs:Small tears can be patched with high-temperature silicone sealant, but replace severely damaged blankets.

Safety Considerations

While Northern Tool welding blankets provide excellent protection, remember:

- They don't make surrounding areas completely fireproof - maintain proper ventilation.

- Always wear appropriate personal protective equipment (PPE) in addition to using the blanket.

- Keep a fire extinguisher nearby when welding, regardless of blanket use.

- Don't use welding blankets as personal protective gear - they're for equipment and surface protection.

Comparing Northern Tool to Other Brands

Northern Tool welding blankets compete well with major brands like Lincoln Electric and Tillman. They offer similar heat resistance at often lower prices, though some premium brands may use slightly thicker materials. For most hobbyists and professionals, Northern Tool provides excellent value.

When to Replace Your Welding Blanket

Replace your Northern Tool welding blanket when you notice:

- Visible holes or thin areas that light passes through

- Stiffness or brittleness that prevents proper draping

- Discoloration that indicates degraded heat resistance

- Loose or missing grommets that compromise secure placement

Alternative Uses Beyond Welding

Northern Tool welding blankets serve other purposes:

- Fireplace spark protection

- Forge and foundry work

- Hot metal transportation

- Temporary heat shielding during automotive repairs

- Protective surface for hot work in woodworking shops

By understanding these features and proper usage techniques, you can maximize safety and get the most value from your Northern Tool welding blanket investment.