Fire Resistant Welding Blankets: Safety Uses and Material Guide

Fire resistant welding blankets protect against sparks, heat, and molten metal during welding. This guide explains their materials, proper use cases, safety benefits, and how to choose the right one for your needs.

What Is a Fire Resistant Welding Blanket?

A fire resistant welding blanket is a safety tool made from heat-resistant materials like fiberglass or silica. You use it to cover flammable surfaces near your work area. These blankets withstand temperatures up to 2000°F (1093°C) while remaining flexible.

Key Benefits for Welders

When you're welding, a fire resistant welding blanket provides three main protections:

- Spark containment:Catches flying sparks that could start fires

- Heat shielding:Protects nearby walls, floors, and equipment

- Molten metal barrier:Prevents slag burns on surfaces below your work

Material Types Compared

Not all fire resistant welding blankets perform the same. Here's what you should know about common materials:

Fiberglass (Most Common)

You'll find these in most workshops. Fiberglass welding blankets handle temperatures up to 1000°F (538°C) and are affordable. They're lightweight but can tear if snagged.

Silica Fabric (Premium Option)

For higher heat up to 2000°F (1093°C), silica welding blankets work best. They're more durable but cost 2-3 times more than fiberglass. Choose these for heavy industrial use.

Carbon Fiber (Specialty Use)

These ultra-thin blankets resist temperatures over 3000°F (1649°C). You'll pay premium prices, but they're essential for aerospace or high-precision welding.

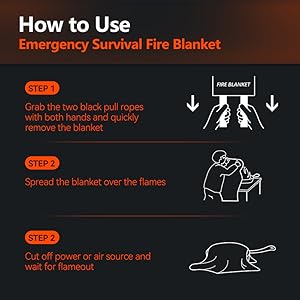

How to Use Properly

Simply having a fire resistant welding blanket isn't enough - you need to use it correctly:

- Cover all flammable surfaces within 35 feet of your welding area

- Overlap multiple blankets by at least 6 inches if covering large areas

- Secure edges with weights or clamps to prevent shifting

- Inspect for holes or thinning areas before each use

Maintenance Tips

Your fire resistant welding blanket lasts longer with proper care:

- Shake out debris after each use - don't brush aggressively

- Store flat or rolled - never fold sharply

- Wash only when necessary using mild detergent

- Replace when more than 10% of fibers show damage

Choosing the Right Size

Measure your work area before buying. Common sizes include:

| Blanket Size | Coverage Area | Best For |

|---|---|---|

| 3' x 4' | Small bench work | Hobbyists |

| 6' x 6' | Vehicle repairs | Auto shops |

| 8' x 10' | Large projects | Construction sites |

Safety Standards to Check

Look for these certifications when buying a fire resistant welding blanket:

- NFPA 2112 (Flame resistance)

- ASTM F955 (Molten metal splash test)

- OSHA 1910.252 (Welding safety compliance)

When to Replace Your Blanket

Even the best fire resistant welding blanket wears out. Replace yours when you notice:

- Visible holes larger than 1 inch

- Stiff, brittle areas that don't flex

- Discoloration covering over 30% of surface

- Reduced effectiveness after 2-3 years of regular use

Investing in quality fire resistant welding blankets protects both your workspace and your safety. Choose the right material and size for your specific welding applications, maintain it properly, and replace when needed for maximum protection.