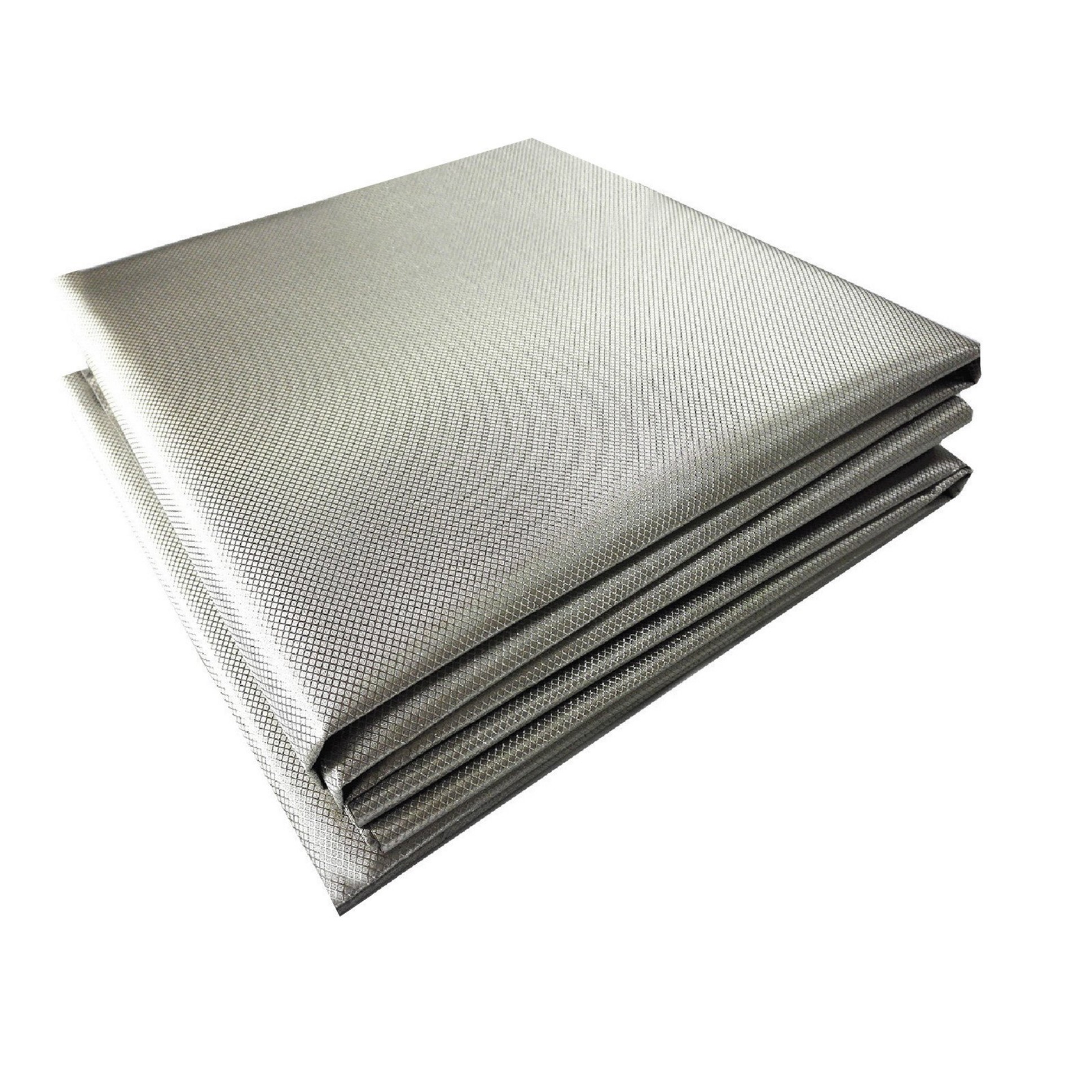

Welding Blanket with Grommets: Heat Protection & Installation Guide

Summary:A welding blanket with grommets provides superior heat protection for industrial and DIY projects. The grommets allow secure mounting, while the fire-resistant material shields surfaces from sparks and molten metal.

What Is a Welding Blanket with Grommets?

When you're welding, cutting, or grinding, sparks and heat can damage nearby surfaces. A welding blanket with grommets solves this problem. It's a flexible, fire-resistant cover made from materials like fiberglass or silica. The metal-reinforced grommets (small holes) along the edges let you hang or secure the blanket in place.

Key Benefits You Should Know

1. Secure Installation:The grommets allow you to tie down the blanket with hooks, wires, or zip ties, preventing it from shifting during work.

2. Multi-Surface Protection:Use it on floors, walls, equipment, or vehicles - anywhere sparks might land.

3. Reusable:Unlike disposable covers, quality welding blankets withstand repeated use when properly maintained.

4. Temperature Resistance:Most withstand 1000°F to 2000°F (540°C to 1100°C), with some industrial-grade options handling even higher temps.

How to Choose the Right One

Material:Fiberglass is common for general use, while silica offers higher heat resistance. Kevlar blends provide durability against abrasion.

Grommet Spacing:12-18 inch spacing works for most applications. Closer spacing (6-12 inches) gives more secure mounting for vertical surfaces.

Thickness:1/16" to 1/8" thickness balances flexibility and protection. Thicker blankets last longer but are less pliable.

Size:Standard sizes range from 3'x3' to 10'x12'. Measure your work area and add 1-2 feet of overlap on all sides.

Proper Installation Techniques

1. Clean the surfacebefore installation to prevent debris from igniting.

2. Use heat-resistant fastenerslike stainless steel hooks or ceramic-coated wires through the grommets.

3. Overlap multiple blanketsby at least 6 inches when covering large areas, securing each layer separately.

4. Maintain tensionto prevent sagging where sparks could accumulate.

Maintenance Tips

• Shake off slag and debris after each use

• Hand wash with mild detergent if heavily soiled (never machine wash)

• Inspect grommets regularly for corrosion or loosening

• Store flat or rolled - never fold, as this weakens the material over time

Safety Considerations

While welding blankets with grommets provide excellent protection, remember:

• They don't make surrounding areas completely fireproof - maintain proper clearance from flammables

• Replace blankets with significant tears or degraded grommets

• Wear appropriate PPE regardless of blanket use

• Never use near open chemical containers or explosive atmospheres

Common Applications

Beyond welding, these versatile blankets work for:

• Metal cutting and grinding operations

• Fireplace and forge protection

• Hot work in automotive repair

• Temporary heat shields during construction

• Protecting sensitive equipment near high-temperature processes

Investing in a quality welding blanket with properly spaced grommets significantly improves worksite safety and protects your valuable surfaces from heat damage. Choose the right specifications for your needs, install it correctly, and maintain it properly for long-lasting protection.