Roll Welding Blanket Guide: Uses, Types and Safety Tips

Summary:Roll welding blankets protect surfaces from sparks and heat during welding. This guide explains their materials, sizes, proper usage, and safety benefits for both professionals and DIYers working with metal.

What Is a Roll Welding Blanket?

When you weld, sparks and molten metal can damage floors or ignite nearby materials. A roll welding blanket solves this problem. These flexible protective covers unroll to create instant workspaces. Unlike rigid shields, they conform to uneven surfaces and wrap around objects.

Key Benefits of Using Roll Welding Blankets

1. Portability:Rolled blankets take minimal storage space and weigh less than 10 lbs for most sizes. Unfurl them wherever needed.

2. Versatility:Use them under welding tables, as wall barriers, or to protect vehicle interiors during auto repairs.

3. Temperature resistance:Quality blankets withstand 1,800°F (982°C) sparks and 500°F (260°C) continuous heat.

4. Reusability:Unlike disposable covers, roll welding blankets last years with proper care.

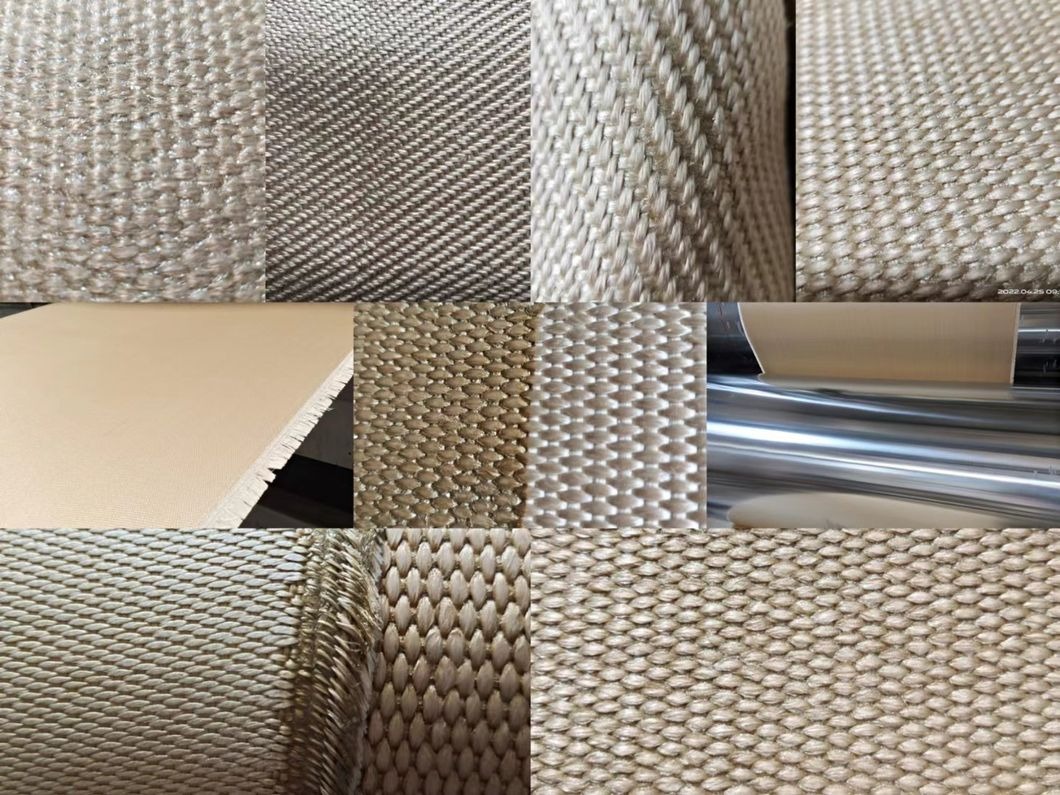

Material Types Compared

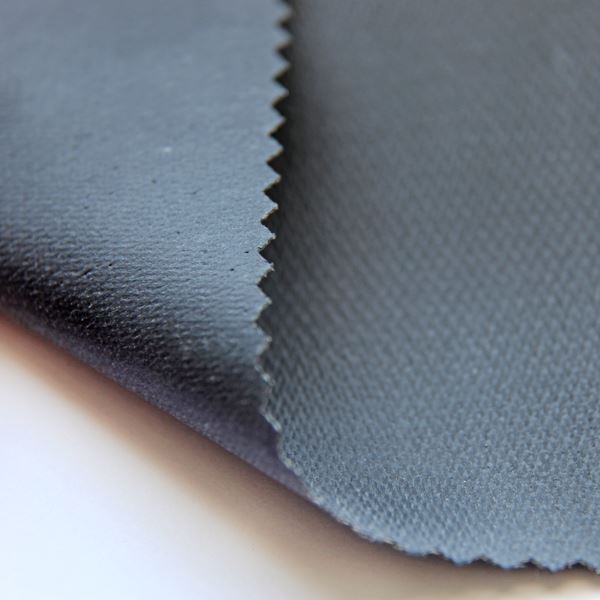

Fiberglass:Most common choice. Offers excellent heat resistance and durability. Look for silicone-coated versions for added strength.

Carbon Fiber:Lighter weight with superior heat deflection. Preferred for aerospace applications.

Ceramic Fiber:Highest temperature rating (up to 2,300°F/1,260°C) but more fragile.

Leather:Traditional option still used in blacksmithing. Requires regular conditioning.

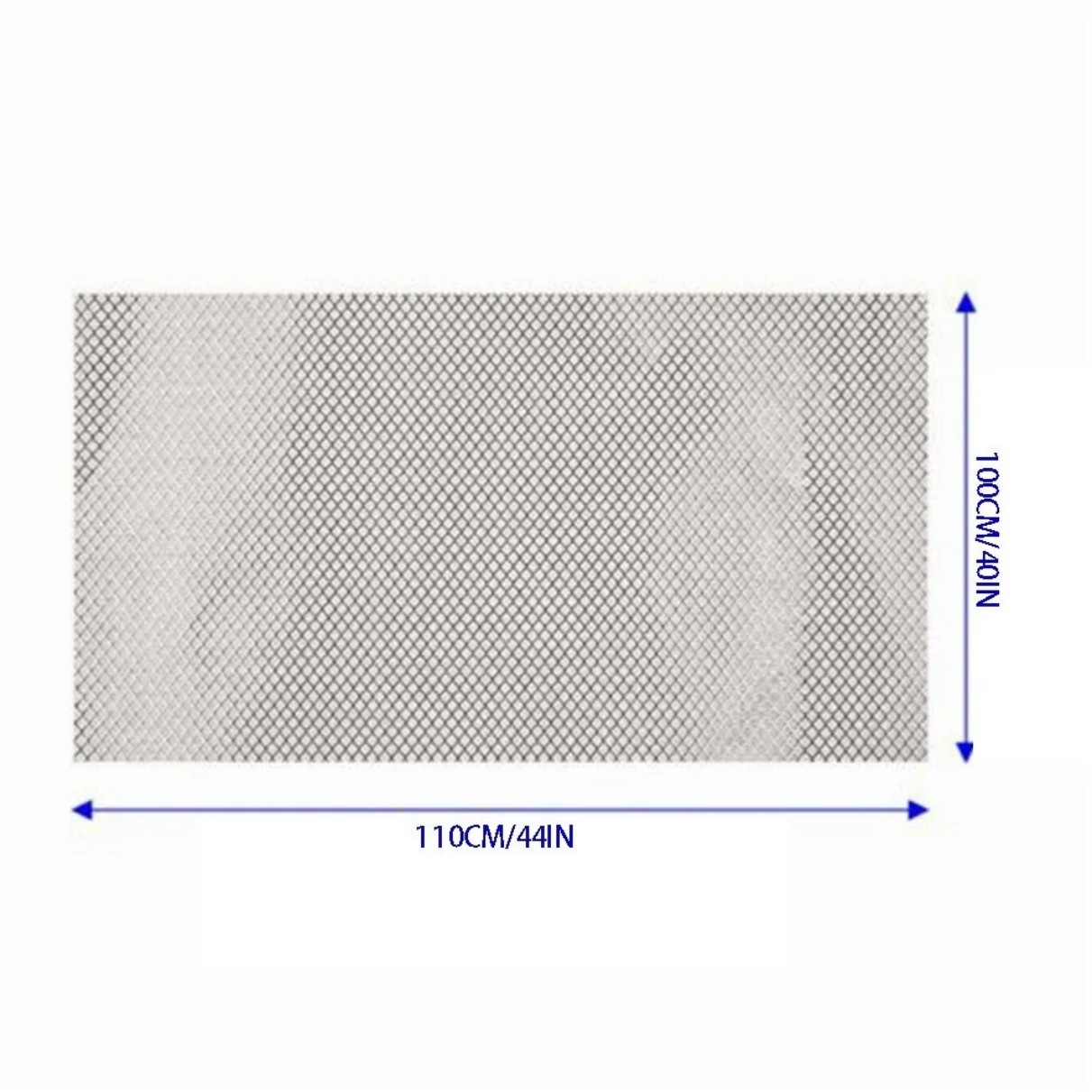

Choosing the Right Size

Measure your work area before selecting a roll welding blanket:

- Small (3'x5'):Bench-top projects

- Medium (4'x6'):Most fabrication tasks

- Large (6'x8'):Floor protection for big jobs

- Custom sizes:Available for industrial applications

Proper Usage Tips

1. Always overlap multiple blankets by 6 inches when covering large areas.

2. Secure edges with welding magnets or non-flammable weights.

3. Position the blanket at least 12 inches from the actual weld point.

4. Inspect for damage before each use - replace if you see holes or fraying.

Maintenance and Care

Your roll welding blanket lasts longer with proper care:

Cleaning:Shake off debris after use. For stubborn residue, use compressed air or a soft brush. Never wash with water.

Storage:Roll loosely (don't fold) and keep in a dry place. Avoid compression that could crease fibers.

Repairs:Small holes can be patched with high-temperature silicone sealant. Replace severely damaged blankets.

Safety Considerations

While roll welding blankets reduce risks, remember:

- They don't replace proper PPE (always wear gloves/helmet)

- Never leave hot blankets near flammable materials

- Allow blankets to cool completely before rolling

- Check manufacturer's temperature limits for your specific model

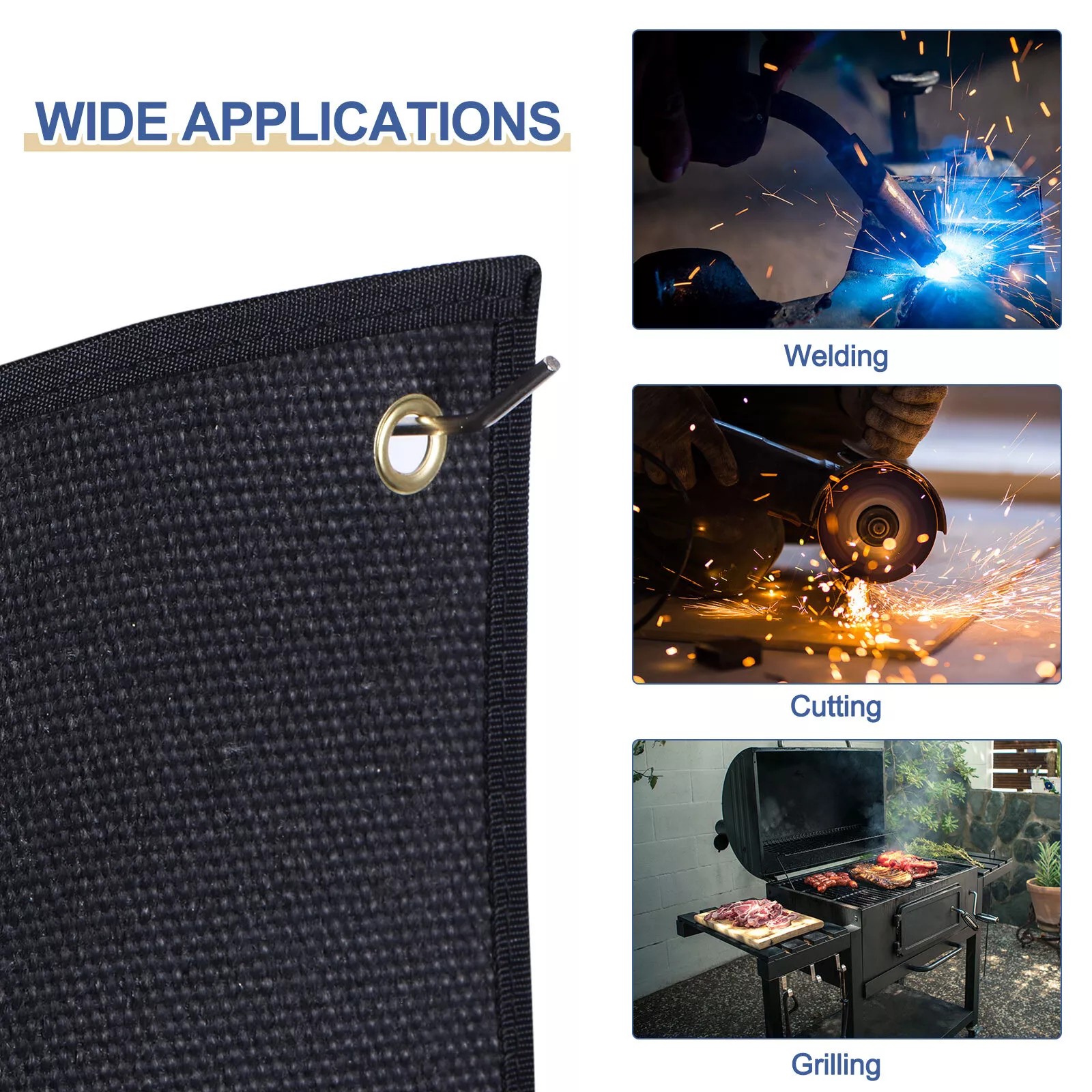

Beyond Welding: Alternative Uses

These versatile tools also work for:

- Grinding spark containment

- Foundry work protection

- Fireplace ember barriers

- Hot pipe insulation during plumbing repairs

Investing in a quality roll welding blanket protects your workspace and prevents costly damage. Choose the right material and size for your projects, follow safety guidelines, and maintain it properly for years of reliable service.