Top 5 Things to Consider When Choosing a Welding Blankets Manufacturer

Summary:Choosing the right welding blankets manufacturer ensures safety and durability. Consider material quality, certifications, customization options, industry experience, and customer support when selecting your supplier.

Why Your Choice of Welding Blankets Manufacturer Matters

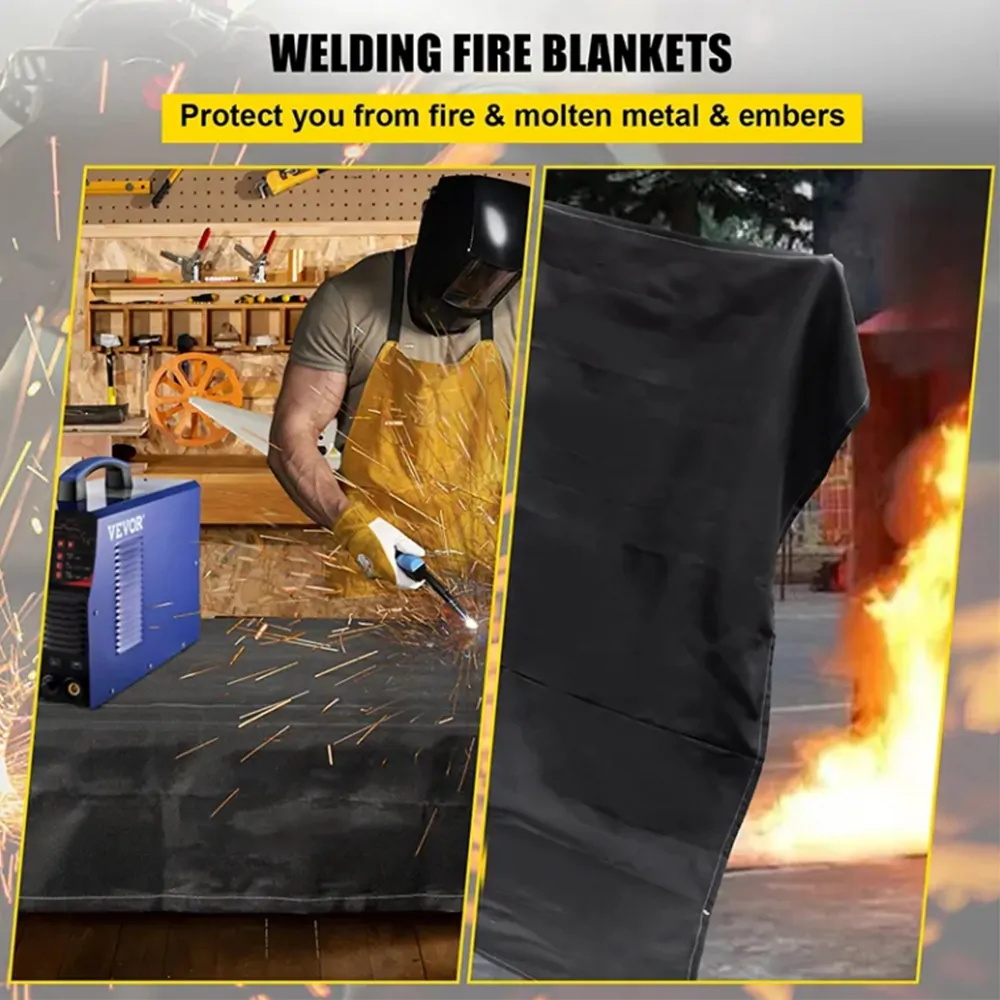

When you need welding blankets for your projects, the manufacturer you choose makes all the difference. High-quality welding blankets protect workers from sparks, heat, and molten metal. A reliable welding blankets manufacturer understands these safety requirements and produces products that meet industry standards.

1. Material Quality and Durability

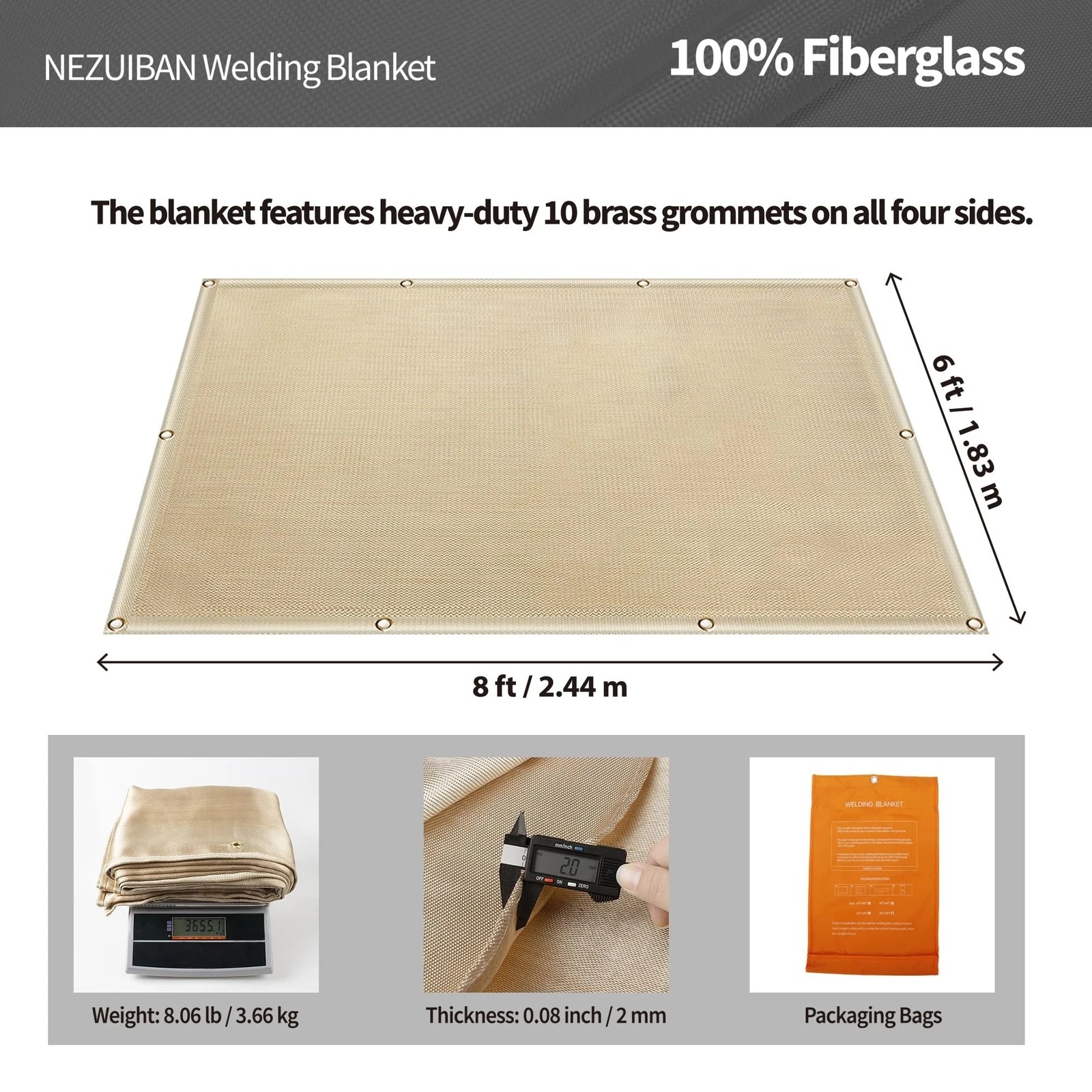

The best welding blankets manufacturers use premium materials like fiberglass, silica, or ceramic fabrics. These materials resist extreme temperatures (up to 2000°F) and provide excellent protection. Ask potential manufacturers about:

- Fabric composition and weight

- Temperature resistance ratings

- Tear and abrasion resistance

- Chemical compatibility

Reputable manufacturers will provide detailed specifications and material test reports.

2. Certifications and Compliance

Your welding blankets manufacturer should comply with relevant safety standards. Look for:

- OSHA compliance for workplace safety

- NFPA 701 fire resistance certification

- ISO 9001 quality management certification

Certified products give you confidence in their performance and safety. Established manufacturers often have these certifications readily available.

3. Customization Options

Every worksite has unique requirements. A good welding blankets manufacturer offers:

- Various sizes (from small patches to large curtains)

- Different thickness options

- Custom shapes for specific equipment

- Color coding for different temperature ratings

- Grommets, straps, or other attachment options

Discuss your specific needs with potential manufacturers to ensure they can accommodate your requirements.

4. Industry Experience and Reputation

Experience matters in protective equipment manufacturing. Consider:

- How long the manufacturer has been in business

- Their client portfolio (do they serve industries similar to yours?)

- Online reviews and testimonials

- Case studies of successful applications

An established welding blankets manufacturer with years of experience will better understand your challenges and provide appropriate solutions.

5. Customer Support and Service

Excellent manufacturers stand behind their products with:

- Knowledgeable technical support

- Clear warranty policies

- Responsive customer service

- Quick turnaround times

- Flexible ordering options

Test their customer service before placing large orders. A quick response to your initial inquiry often indicates how they'll handle future concerns.

Maintenance Tips for Welding Blankets

Even the best welding blankets from top manufacturers need proper care. Follow these guidelines:

- Inspect regularly for tears or damage

- Clean according to manufacturer instructions

- Store properly when not in use

- Replace when protective qualities diminish

Your welding blankets manufacturer should provide specific maintenance recommendations for their products.

Conclusion

Choosing the right welding blankets manufacturer ensures you get durable, safe, and effective protection for your welding operations. By considering material quality, certifications, customization options, experience, and customer service, you'll find a reliable partner for your safety needs. Always request samples and test products before making large purchases.