Silica Welding Blankets: Heat Protection Solutions for Industrial Applications

Summary:Silica welding blankets provide superior heat protection for welding, foundries, and high-temperature applications. These flexible, durable barriers resist sparks, slag, and radiant heat up to 2000°F while remaining lightweight and easy to handle.

What Are Silica Welding Blankets?

Silica welding blankets are specialized protective covers made from amorphous silica fibers. Unlike traditional welding blankets, they offer exceptional thermal insulation without containing asbestos or other hazardous materials. You'll find them in various thicknesses (typically 1/4" to 1") to match different temperature requirements.

Key Benefits of Using Silica Welding Blankets

When you work with high temperatures, silica welding blankets provide multiple advantages:

- Extreme heat resistance:Withstands continuous exposure to 1800°F-2000°F (982°C-1093°C)

- Lightweight flexibility:Easier to handle than ceramic fiber blankets while offering similar protection

- Non-combustible:Won't catch fire or contribute to flame spread

- Chemical resistance:Impervious to most acids, oils, and solvents

- Low thermal conductivity:Effectively blocks radiant heat transfer

Common Applications in Industry

You'll find silica welding blankets used across multiple sectors:

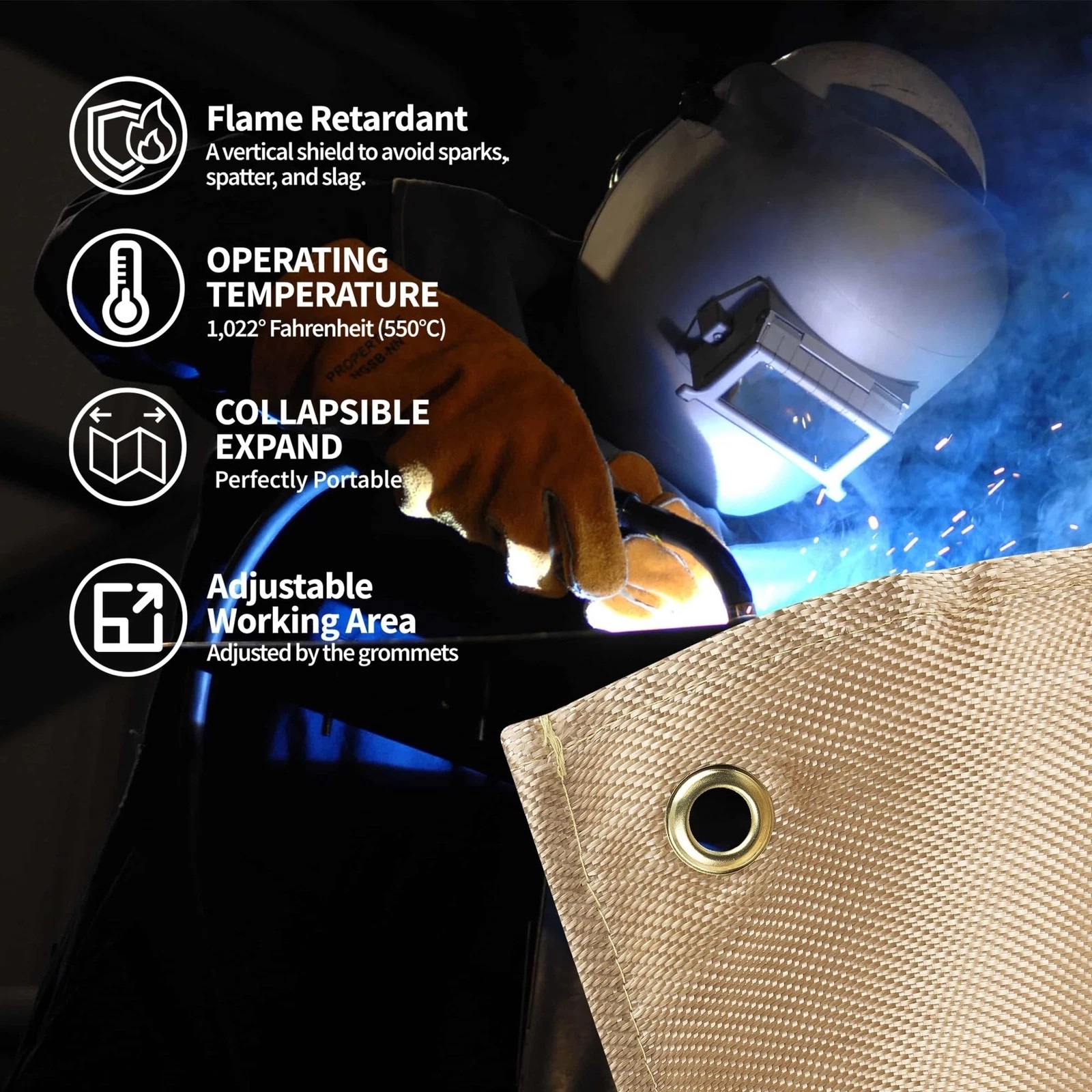

Welding Operations:Protect nearby equipment, walls, and workers from sparks and spatter during arc welding, plasma cutting, or oxy-fuel processes. The blankets drape easily over irregular shapes.

Foundry Work:Cover molten metal containers, ladles, or pouring areas to contain heat and prevent accidental contact.

Power Plants:Insulate pipes, valves, and turbines where traditional insulation would be impractical.

Aerospace:Shield sensitive components during high-temperature curing or testing procedures.

Choosing the Right Silica Welding Blanket

Consider these factors when selecting your blanket:

- Temperature rating:Match the maximum exposure temperature to your application needs

- Thickness:Thicker blankets (1/2" or more) provide better insulation for prolonged heat

- Size:Measure the area needing coverage with some overlap for complete protection

- Reinforcement:Some models include wire mesh or stitching for added durability

- Color coding:White blankets typically indicate higher purity silica for critical applications

Proper Use and Maintenance

To get the most from your silica welding blanket:

- Always wear gloves when handling to prevent fiber irritation

- Store flat or rolled (never folded) to prevent crease damage

- Inspect regularly for tears or thinning areas

- Clean with compressed air—never wash with liquids

- Replace when the blanket becomes brittle or shows significant wear

Safety Considerations

While silica welding blankets are safer than asbestos alternatives, you should still:

- Work in well-ventilated areas when cutting or shaping blankets

- Wear PPE (gloves, long sleeves, eye protection) during installation

- Follow OSHA guidelines for handling fibrous materials

- Dispose of worn blankets properly according to local regulations

Comparing Silica to Other Welding Blanket Materials

Silica outperforms many alternatives:

| Material | Max Temp | Weight | Flexibility |

|---|---|---|---|

| Silica | 2000°F | Light | High |

| Fiberglass | 1000°F | Medium | Medium |

| Ceramic Fiber | 2300°F | Heavy | Low |

| Leather | 500°F | Heavy | Medium |

Innovations in Silica Welding Blanket Technology

Recent advancements include:

- Multi-layer constructions combining silica with reflective barriers

- Anti-static treatments for explosive environments

- Custom shapes pre-cut for specific equipment

- High-visibility edges for safety in busy work areas

Silica welding blankets remain essential safety tools for high-temperature work. By understanding their properties and proper use, you can significantly improve workplace safety while maintaining efficiency in your thermal processes.