Kevlar Welding Blankets: Ultimate Heat Protection for Industrial Safety

Summary:Kevlar welding blankets provide superior heat resistance and protection during welding operations. These durable safety tools shield workers and equipment from sparks, slag, and extreme temperatures in industrial environments.

What Is a Kevlar Welding Blanket?

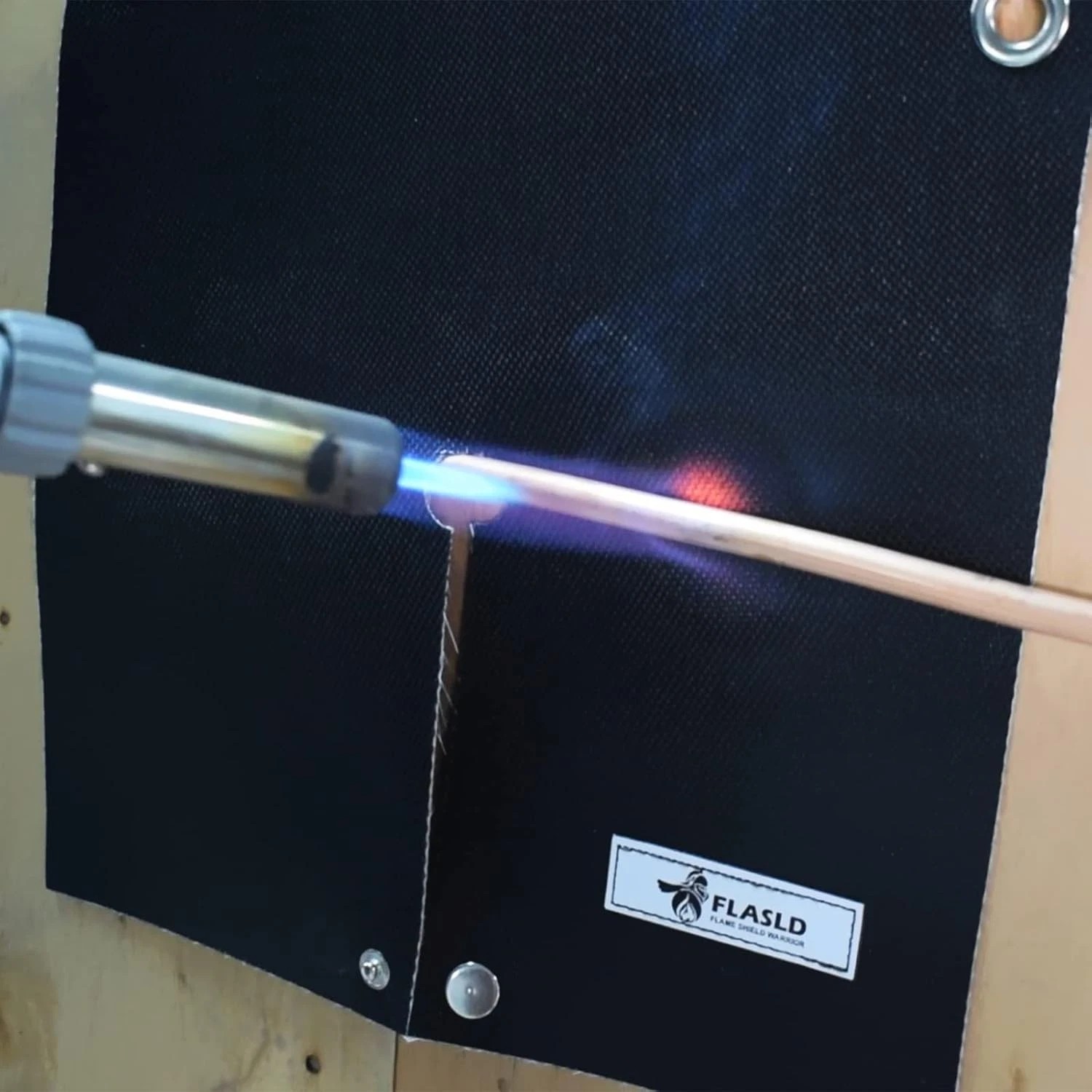

When you're working with high-temperature processes like welding, you need reliable protection. A Kevlar welding blanket is a specialized safety device made from Kevlar fibers that can withstand temperatures up to 800°F (427°C). Unlike ordinary fabrics, Kevlar won't melt or catch fire when exposed to welding sparks or molten metal splatter.

Key Benefits of Using Kevlar Welding Blankets

You'll appreciate these advantages when using Kevlar welding blankets:

- Extreme heat resistance:Protects against direct flame and radiant heat

- Durability:Resists tears and abrasions better than fiberglass alternatives

- Lightweight:Easier to handle than traditional welding curtains

- Flexibility:Can be draped over irregular shapes and surfaces

- Reusable:Withstands multiple uses without degradation

How to Choose the Right Kevlar Welding Blanket

Selecting the proper Kevlar welding blanket depends on your specific needs. Consider these factors:

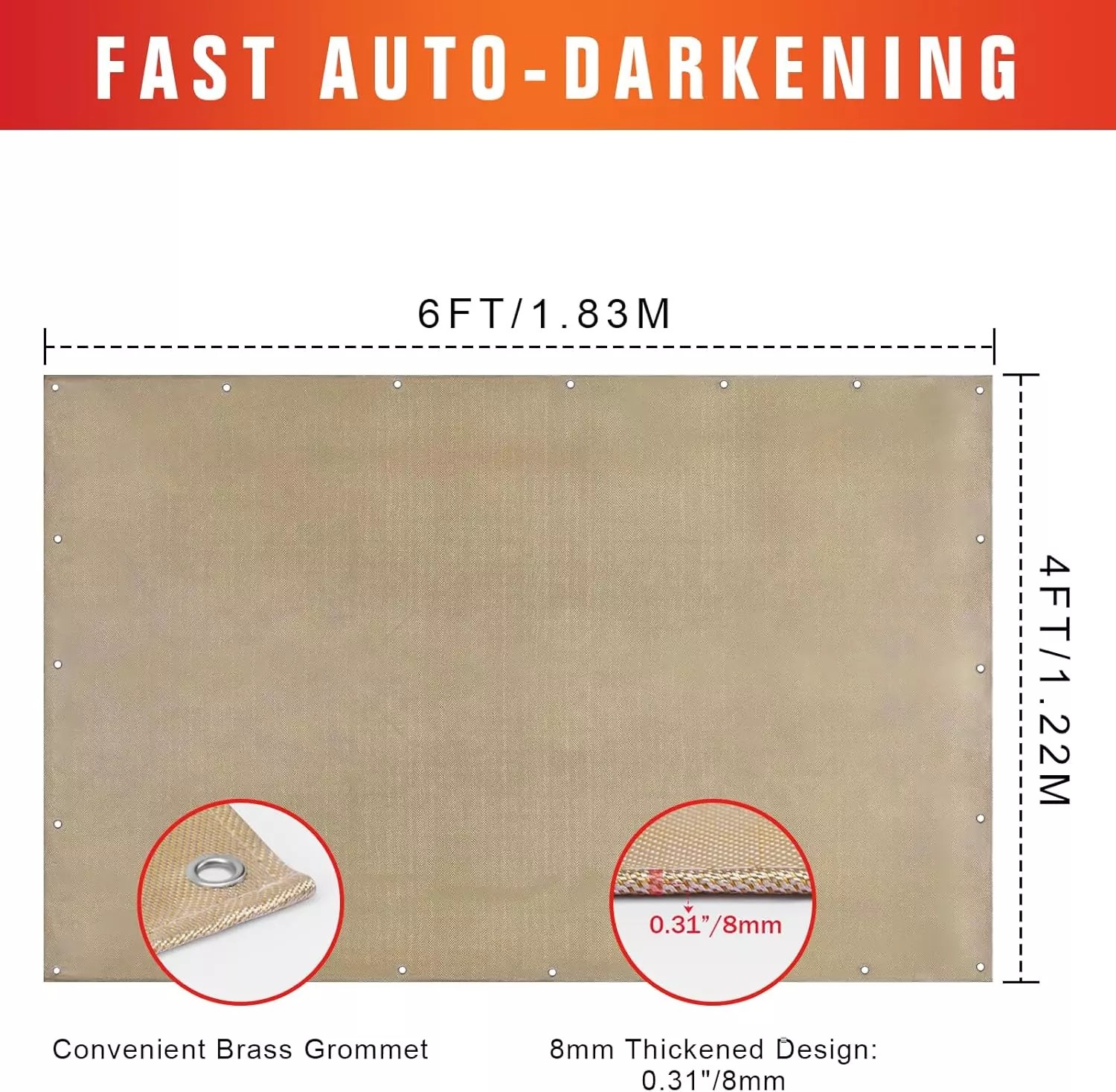

Size:Measure your work area - common sizes range from 4'x4' to 10'x10'. Larger blankets provide more coverage but may be harder to maneuver.

Thickness:Thicker blankets (typically 1/8" to 1/4") offer better protection but are less flexible.

Attachment options:Look for grommets or hooks if you need to hang your blanket.

Color:While most are natural Kevlar yellow, some manufacturers offer colored options for visibility.

Proper Use and Maintenance

To get the most from your Kevlar welding blanket:

- Inspect regularly for damage before each use

- Keep away from sharp edges that could puncture the material

- Clean with compressed air or a soft brush - avoid harsh chemicals

- Store flat or rolled - never fold, as this weakens the fibers

- Replace when you notice significant wear or reduced performance

Kevlar vs. Other Welding Blanket Materials

How does Kevlar compare to alternatives?

| Material | Max Temperature | Weight | Durability |

|---|---|---|---|

| Kevlar | 800°F | Light | Excellent |

| Fiberglass | 1000°F | Medium | Good |

| Leather | 500°F | Heavy | Fair |

While fiberglass handles slightly higher temperatures, Kevlar offers better durability and flexibility for most welding applications.

Safety Standards and Certifications

Quality Kevlar welding blankets should meet these standards:

- NFPA 701 (fire resistance)

- OSHA 1910.252 (welding safety)

- ASTM F955 (molten metal splash protection)

Always verify certifications before purchasing to ensure proper protection.

Applications Beyond Welding

Your Kevlar welding blanket has multiple uses:

- Foundry work

- Fire training exercises

- Hot work in confined spaces

- Protecting sensitive equipment near heat sources

- Emergency fire containment

Conclusion

A Kevlar welding blanket is an essential safety tool for any welding operation. Its combination of heat resistance, durability, and flexibility makes it superior to traditional materials. By choosing the right size and thickness for your needs and maintaining it properly, you'll get reliable protection that lasts through countless projects. Invest in quality Kevlar protection - your safety is worth it.