NFPA 51B Welding Blanket Safety Guide & Best Practices

This guide explains how NFPA 51B welding blankets protect against fire hazards during hot work. You'll learn about standards, proper selection, installation, and maintenance to ensure workplace safety.

What Are NFPA 51B Welding Blankets?

NFPA 51B welding blankets are fire-resistant covers designed to protect surfaces from sparks, slag, and heat during welding, cutting, and other hot work. The NFPA 51B standard specifies safety requirements for these protective barriers in industrial settings.

These blankets serve three primary functions:

- Prevent ignition of flammable materials

- Contain sparks and molten metal

- Protect workers from radiant heat

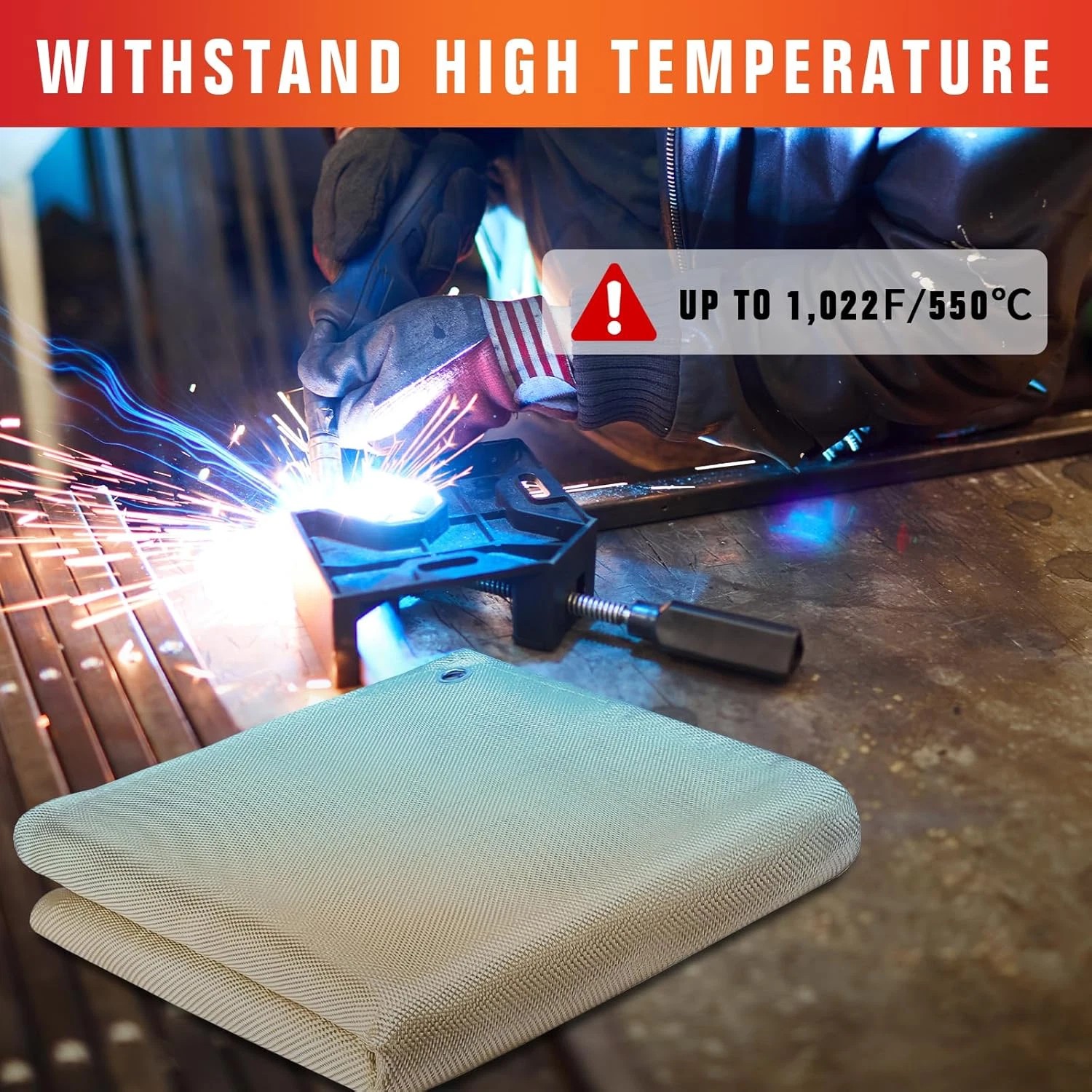

Key Requirements in NFPA 51B Standard

The NFPA 51B standard outlines specific criteria for welding blankets:

- Must withstand temperatures up to 1,800°F (982°C)

- Require flame-resistant certification

- Need proper thickness for intended use

- Must cover all exposed surfaces within 35 feet of hot work

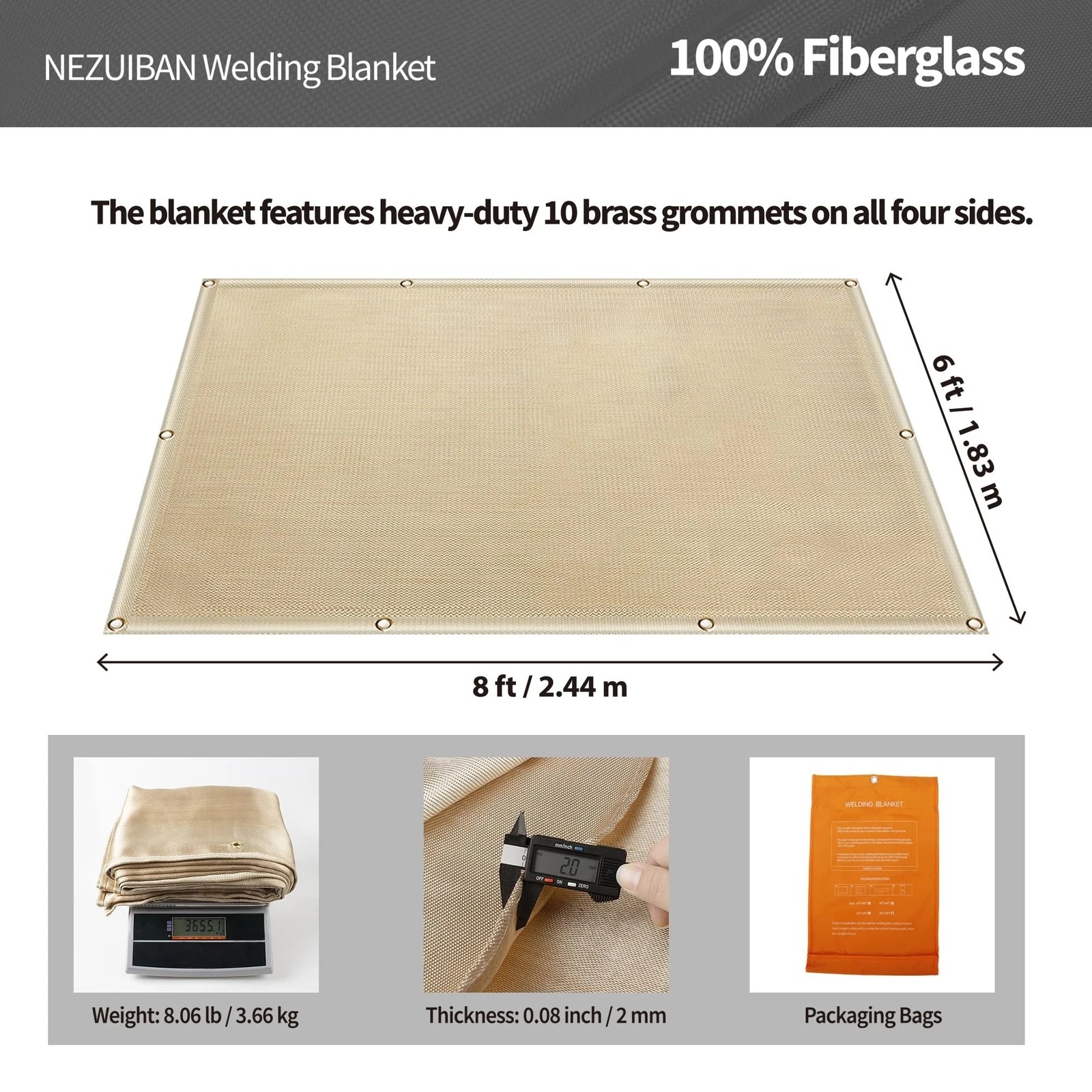

How to Choose the Right Welding Blanket

Selecting proper NFPA 51B welding blankets depends on your specific application:

- Material:Fiberglass (most common), silica, or ceramic options

- Thickness:1/16" for light duty, 1/8" for standard, 1/4" for heavy duty

- Size:Cover all potential spark travel areas with overlap

- Certification:Look for NFPA 51B compliance markings

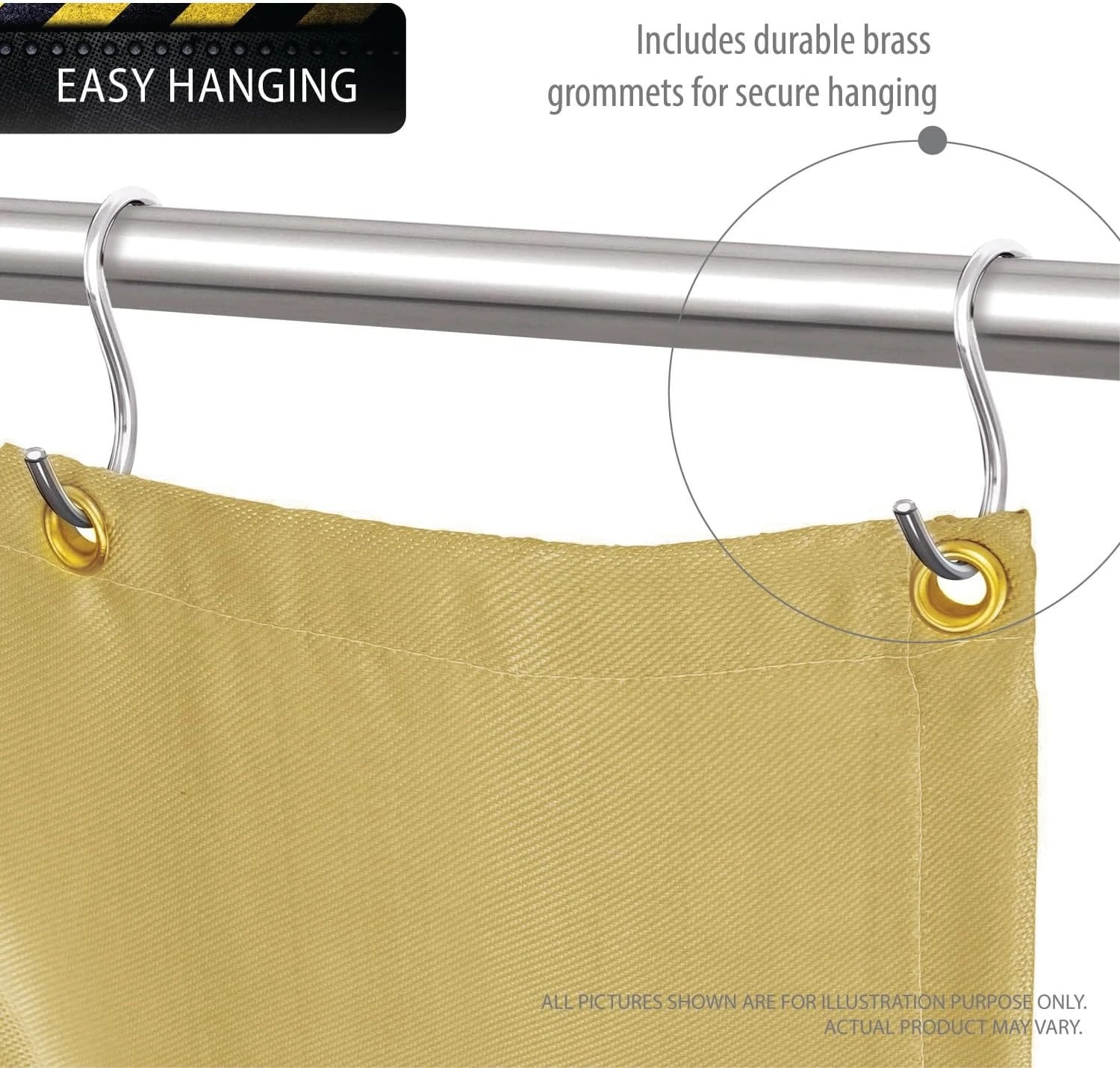

Proper Installation Techniques

Correct installation maximizes NFPA 51B welding blanket effectiveness:

- Inspect for damage before each use

- Secure tightly with non-combustible fasteners

- Overlap seams by at least 6 inches

- Extend coverage 3 feet beyond work area

- Keep blankets clean and dry

Maintenance and Inspection

Regular maintenance ensures NFPA 51B welding blankets remain effective:

- Check for holes, tears, or thinning areas weekly

- Replace when more than 10% surface shows damage

- Clean with compressed air or soft brush (no chemicals)

- Store flat or rolled (never folded) in dry conditions

Common Mistakes to Avoid

Many accidents occur due to improper use of welding blankets:

- Using blankets not rated for your temperature range

- Failing to secure edges properly

- Reusing damaged blankets

- Placing blankets over live electrical components

- Assuming blankets eliminate need for fire watch

Beyond NFPA 51B: Additional Safety Measures

While NFPA 51B welding blankets provide essential protection, combine them with:

- Fire extinguishers rated for metal fires

- Proper ventilation systems

- Trained fire watch personnel

- Personal protective equipment (PPE)

- Regular safety training updates

By following NFPA 51B standards and these best practices, you create a safer work environment for all hot work operations. Always consult the latest NFPA 51B edition for current requirements.