Professional Fiberglass Welding Blanket: Ultimate Protection Guide

This guide explains why professional fiberglass welding blankets are essential safety tools. You'll learn their key features, benefits over alternatives, proper usage techniques, and maintenance tips for maximum protection during welding operations.

Why Choose Professional Fiberglass Welding Blankets?

When you're working with high-temperature welding processes, ordinary materials won't provide adequate protection. Professional fiberglass welding blankets offer superior heat resistance, typically withstanding temperatures up to 2000°F (1093°C). Their woven fiberglass construction creates a flexible yet durable barrier against sparks, slag, and molten metal splatter.

Unlike cheaper alternatives, professional-grade blankets use high-silica content fiberglass that won't melt or degrade quickly. You'll notice the difference in quality immediately - these blankets maintain their integrity even after repeated exposure to intense heat.

Key Features to Look For

When selecting your professional fiberglass welding blanket, check these essential features:

- Temperature rating- Should match your specific welding applications

- Reinforced edges- Prevents fraying and extends service life

- Proper thickness- Thicker blankets (1/8" or more) offer better protection

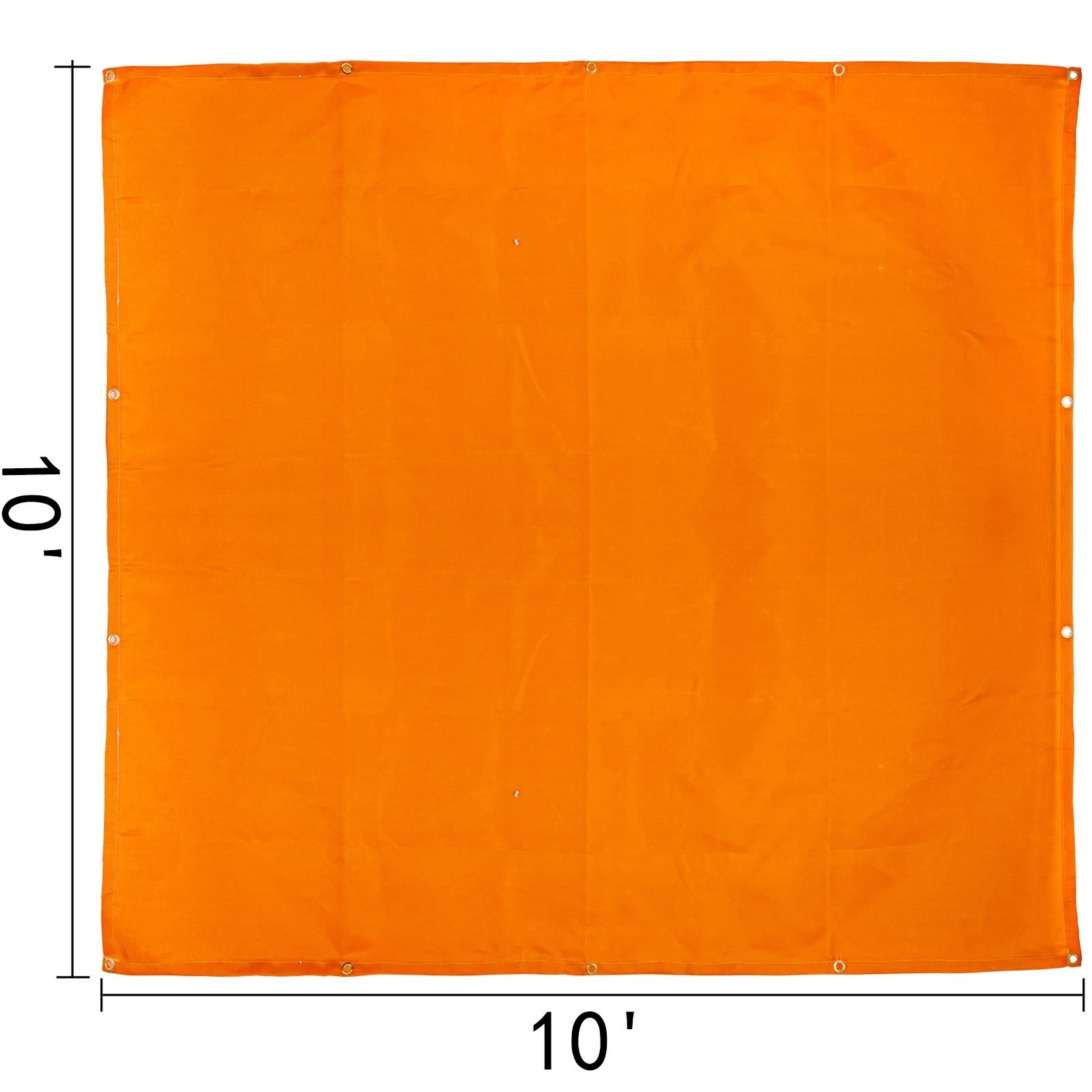

- Size options- Choose coverage appropriate for your work area

- Chemical resistance- Important for industrial environments

Proper Usage Techniques

To get maximum protection from your professional fiberglass welding blanket:

- Always inspect the blanket for damage before use

- Position it to protect surrounding areas from sparks and heat

- Secure it properly to prevent movement during work

- Use multiple layers for extra protection in high-heat applications

- Keep flammable materials away from the covered area

Remember that while professional fiberglass welding blankets are highly effective, they should complement other safety measures like proper ventilation, protective clothing, and eyewear.

Maintenance and Care

Proper care extends your professional fiberglass welding blanket's lifespan:

- Shake out debris after each use

- Store in a dry, clean area when not in use

- Inspect regularly for tears or excessive wear

- Clean with compressed air or a soft brush - avoid water

- Replace when fibers become brittle or protection diminishes

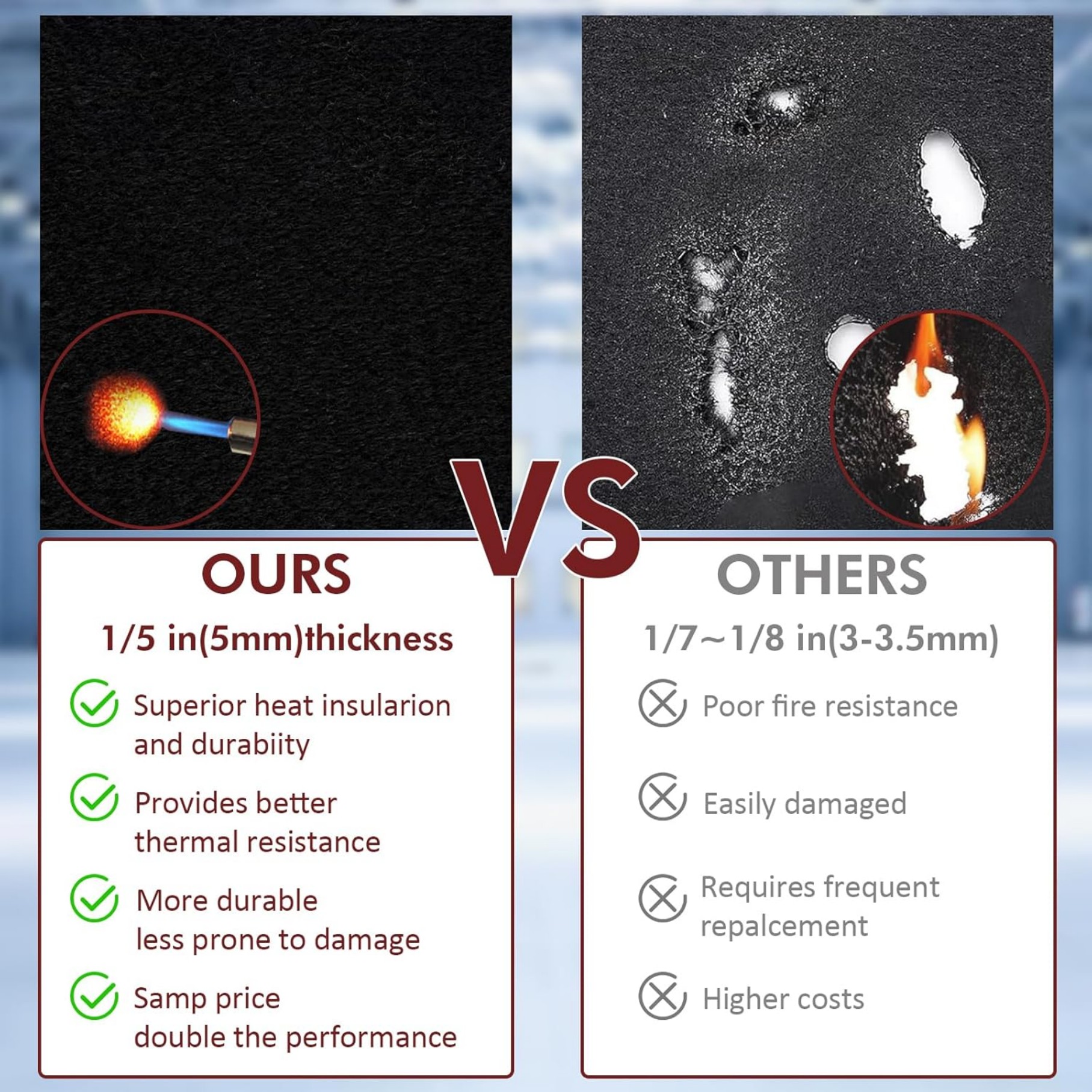

Comparing Professional vs. Standard Blankets

While standard welding blankets may seem cost-effective initially, professional fiberglass welding blankets offer significant advantages:

| Feature | Professional Blanket | Standard Blanket |

|---|---|---|

| Temperature Resistance | Up to 2000°F | Typically 1000-1500°F |

| Durability | Years of service | Months to 1 year |

| Safety Standards | Meets industrial requirements | Basic protection only |

| Chemical Resistance | High | Limited |

Applications Beyond Welding

While designed for welding, professional fiberglass welding blankets have multiple uses:

- Foundry work and metal casting

- Fireproofing during hot work operations

- Protecting surfaces during grinding or cutting

- Emergency fire containment

- Heat shielding in automotive applications

Safety Considerations

Even with professional fiberglass welding blankets, observe these precautions:

- Never use damaged blankets - replace immediately

- Avoid direct contact with molten metal

- Ensure proper ventilation when welding

- Wear appropriate PPE in addition to blanket protection

- Keep fire extinguishers accessible

Investing in a quality professional fiberglass welding blanket protects your workspace, equipment, and most importantly - you. The initial higher cost pays for itself through superior protection and longer service life.