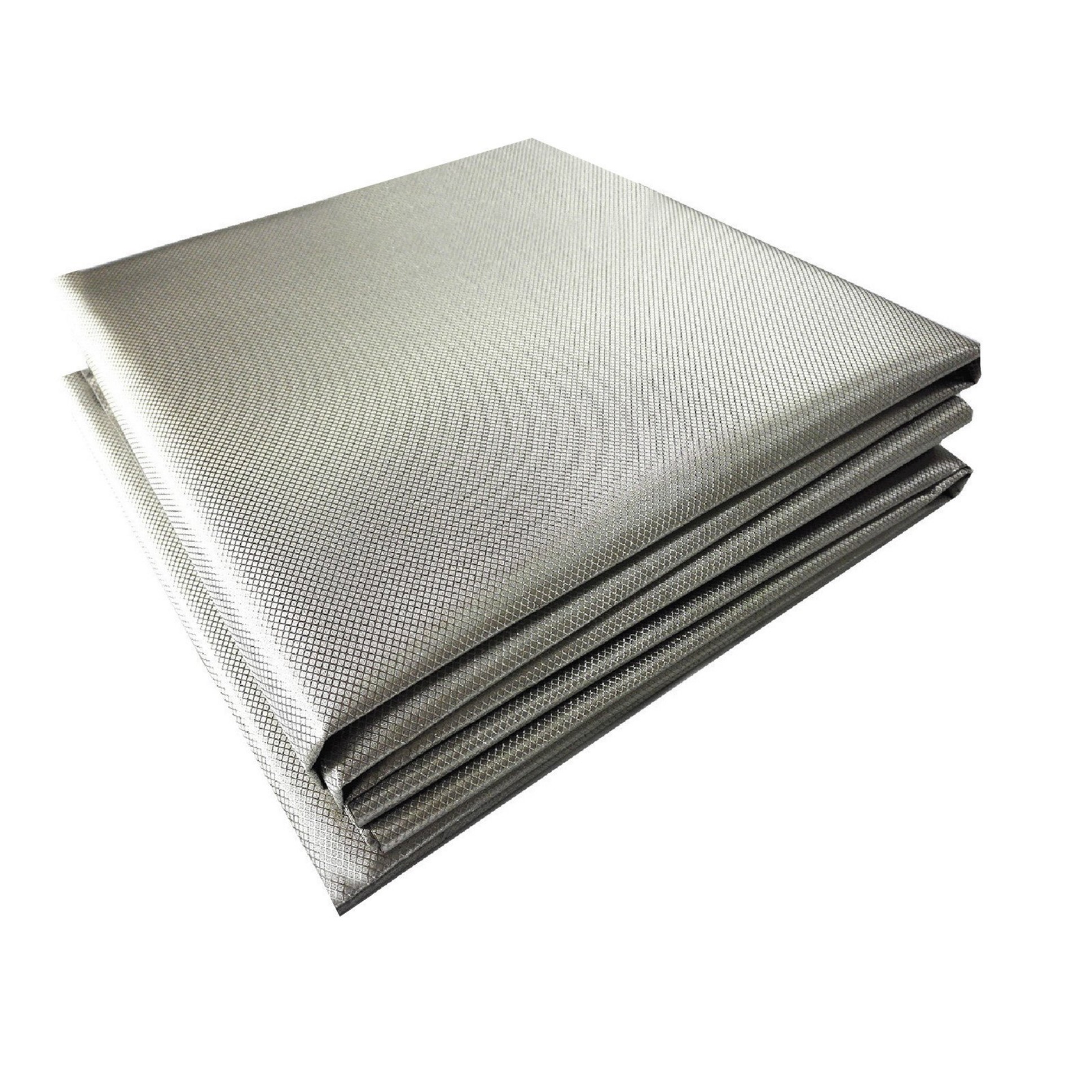

Fire Resistant Welding Blankets: Essential Protection for Hot Work Safety

Fire resistant blankets for welding protect workers and surfaces from sparks, slag, and heat. These specialized safety tools are essential in metalworking, construction, and industrial settings. This guide explains their benefits, materials, proper use, and selection criteria.

Why You Need a Fire Resistant Blanket for Welding

When you're welding, cutting, or grinding metal, sparks and molten particles can travel several feet. A fire resistant welding blanket acts as a protective barrier that:

- Prevents fires by containing sparks and hot debris

- Protects nearby workers from burns

- Safeguards flammable materials and equipment

- Creates a designated safe work area

Unlike regular blankets, these are specifically designed to withstand temperatures up to 1,800°F (982°C) depending on the material.

Materials Used in Fire Resistant Welding Blankets

Quality matters when choosing your fire resistant blanket for welding. The most common materials include:

- Fiberglass:The most affordable option, resistant to temperatures up to 1,000°F (538°C)

- Silica:Handles up to 1,800°F (982°C) and offers better durability

- Carbon Fiber:Premium choice with excellent heat reflection properties

- Ceramic Fiber:For extreme heat applications above 2,000°F (1,093°C)

Many blankets combine these materials with fire-retardant coatings for enhanced protection.

How to Properly Use Your Welding Blanket

Simply having a fire resistant blanket isn't enough - you need to use it correctly:

- Inspect the blanket for damage before each use

- Position it to cover all vulnerable areas within spark range

- Secure it with non-flammable weights or clamps to prevent movement

- Overlap multiple blankets if your work area is large

- Keep the blanket clean - accumulated debris can reduce effectiveness

Remember that welding blankets are single-purpose safety equipment. Never use them as personal protective equipment (PPE) or wear them like clothing.

Choosing the Right Fire Resistant Blanket for Your Needs

Consider these factors when selecting your welding blanket:

- Temperature rating:Match it to your specific welding processes

- Size:Measure your work area and add safety margins

- Weight:Heavier blankets stay in place better but are less portable

- Flexibility:Some applications require draping over irregular shapes

- Certifications:Look for NFPA 701, ASTM, or other relevant standards

For occasional light welding, a basic fiberglass blanket may suffice. Industrial operations typically need silica or ceramic fiber blankets.

Maintenance and Care Tips

Proper care extends your fire resistant blanket's lifespan:

- Shake off debris after each use

- Store folded or rolled in a dry, clean area

- Wash only if absolutely necessary, following manufacturer instructions

- Inspect regularly for tears, thinning, or stiffening

- Replace when damaged or when the material becomes brittle

Most quality welding blankets last 1-3 years with regular use, depending on frequency and conditions.

Beyond Welding: Other Applications

While designed for welding, these versatile blankets also work well for:

- Foundry work and metal casting

- Fire containment during hot work permits

- Protecting surfaces during grinding or cutting operations

- Emergency fire suppression (as a last resort)

Always check the manufacturer's specifications for approved uses beyond welding applications.

Safety First: Limitations to Remember

While fire resistant blankets for welding are essential safety tools, they have limitations:

- They don't replace proper ventilation systems

- Direct flame contact can still damage them over time

- They're not designed for electrical fire suppression

- Chemical spills may compromise their fire resistance

Always combine blanket use with other appropriate safety measures like proper PPE and fire extinguishers.