Felt Welding Blanket Guide: Protection, Uses, and Safety Tips

Summary:Felt welding blankets protect against sparks, heat, and molten metal. This guide explains their benefits, proper usage, material properties, and safety applications in welding and industrial settings.

What Is a Felt Welding Blanket?

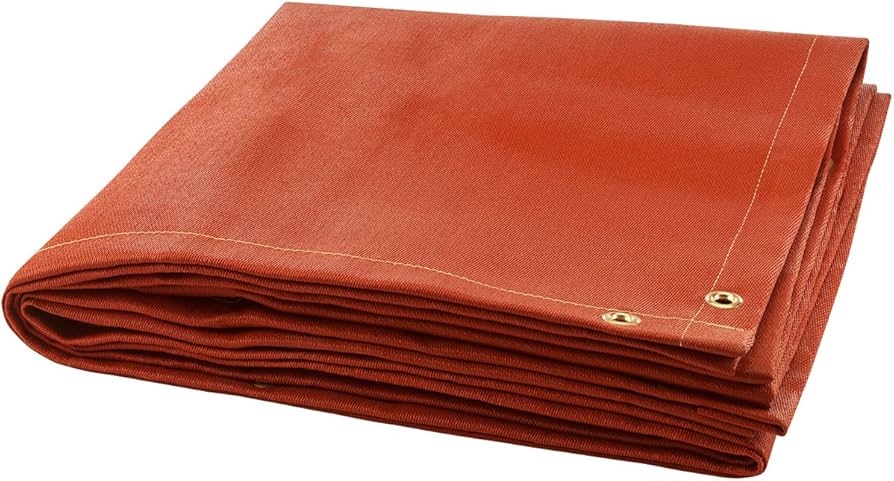

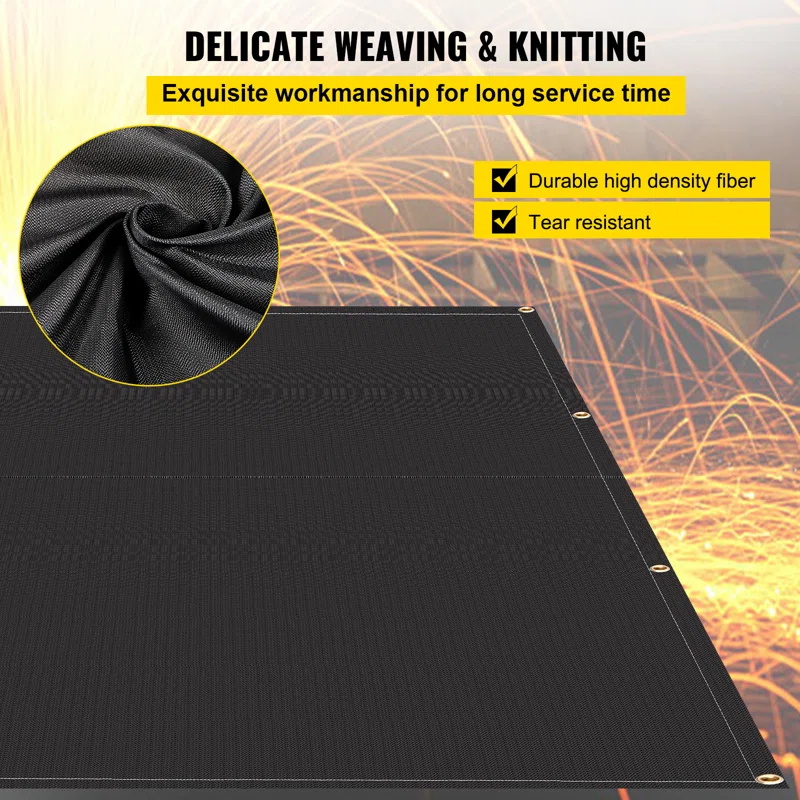

When you work with welding equipment, protection matters. A felt welding blanket is a heat-resistant safety tool made from compressed wool or synthetic fibers. Unlike fiberglass blankets, felt offers superior insulation and spark containment. You'll find these blankets in workshops, construction sites, and industrial facilities.

Key Benefits of Using Felt Welding Blankets

Why choose felt over other materials? Here's what makes them special:

- Heat resistance:Withstands temperatures up to 1,800°F (982°C)

- Spark containment:Prevents fire hazards by trapping welding sparks

- Durability:Lasts longer than standard fiberglass blankets

- Flexibility:Easily drapes over irregular surfaces

- Reusability:Can be used repeatedly without performance loss

Proper Usage of Felt Welding Blankets

To get maximum protection from your felt welding blanket:

- Cover all flammable surfaces within 35 feet of your work area

- Overlap multiple blankets by at least 6 inches when covering large areas

- Secure edges with weights or clamps to prevent movement

- Inspect for damage before each use - replace if you see holes or thinning

- Store flat or rolled (never folded) to prevent crease damage

Choosing the Right Felt Welding Blanket

Not all felt welding blankets perform equally. Consider these factors:

| Feature | Standard Grade | Industrial Grade |

|---|---|---|

| Material | Wool/synthetic blend | 100% refractory wool |

| Max Temperature | 1,500°F (816°C) | 2,000°F (1,093°C) |

| Thickness | 1/4 inch | 1/2 inch |

| Best For | Light welding, occasional use | Heavy industrial applications |

Maintenance and Care Tips

Your felt welding blanket will last longer with proper care:

- Shake out debris after each use - never wash with water

- Hang to air out if exposed to chemicals or moisture

- Store in a dry, rodent-free area

- Mark damaged areas with heat-resistant tape as temporary repair

- Replace every 2-3 years with regular use

Safety Applications Beyond Welding

While designed for welding, these blankets have multiple uses:

- Protecting floors during hot work operations

- Covering machinery during fire risks

- Emergency fire containment (small fires only)

- Insulating pipes and valves

- Creating safe zones for grinding operations

Common Mistakes to Avoid

Even experienced workers sometimes misuse felt welding blankets:

- Using as personal protective equipment (it's for equipment/area protection)

- Folding rather than rolling for storage (causes weak spots)

- Ignoring small holes (they compromise the entire blanket's effectiveness)

- Using near open chemical containers (some chemicals degrade the fibers)

Remember - a quality felt welding blanket is an investment in safety. Choose the right grade for your needs, use it properly, and maintain it well. This simple tool can prevent costly fires and injuries in your workplace.