Fire Retardant Welding Blankets: Essential Safety Gear for Welders

Summary:Fire retardant welding blankets protect against sparks, heat, and molten metal during welding. Made from durable materials, they prevent fires and injuries. This guide explains their benefits, types, and proper use for maximum safety.

Why You Need Fire Retardant Welding Blankets

When you're welding, sparks and molten metal can travel several feet. Fire retardant welding blankets create a protective barrier that prevents these hazards from igniting nearby materials. Unlike regular blankets, they won't catch fire or melt when exposed to extreme heat (typically up to 1,800°F/982°C).

Key Features of Quality Welding Blankets

Look for these characteristics when choosing fire retardant welding blankets:

- Material:Fiberglass or silica fabric with fire-resistant coatings

- Temperature resistance:Minimum 1,000°F (538°C) rating

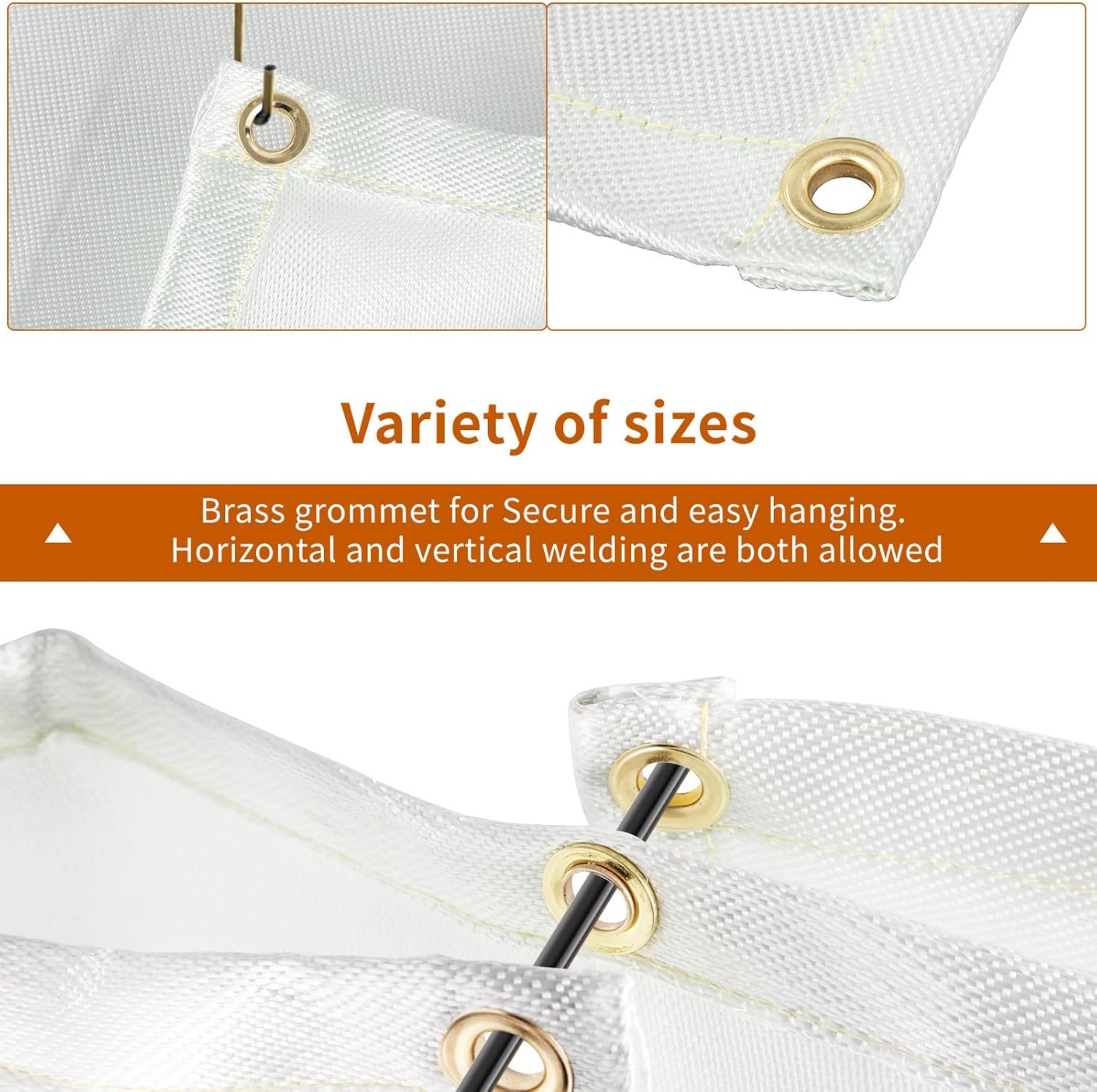

- Durability:Reinforced edges and tear-resistant construction

- Size options:Typically 3'x4' to 12'x12' for different work areas

- Flexibility:Should drape easily over irregular surfaces

Proper Use of Welding Blankets

To get maximum protection from your fire retardant welding blankets:

- Cover all flammable materials within 35 feet of your work area

- Overlap multiple blankets by at least 6 inches when covering large areas

- Secure blankets with non-flammable weights or clamps to prevent shifting

- Inspect blankets before each use for holes or worn areas

- Store clean and dry to maintain fire resistance

Types of Fire Retardant Welding Blankets

Different welding applications require specific blanket types:

| Type | Best For | Temperature Range |

|---|---|---|

| Fiberglass | General welding, grinding | Up to 1,000°F (538°C) |

| Silica | High-temperature welding | Up to 1,800°F (982°C) |

| Aluminized | Reflective heat protection | Up to 2,000°F (1,093°C) |

Maintenance and Safety Tips

Your fire retardant welding blankets last longer and work better with proper care:

- Clean with mild soap and water - never use harsh chemicals

- Air dry completely before storage

- Replace blankets that show significant wear or damage

- Never use welding blankets as personal protective equipment (wear proper PPE)

- Keep multiple blankets on hand for large projects

Common Mistakes to Avoid

Even experienced welders sometimes make these errors with fire retardant welding blankets:

- Using blankets that are too small for the work area

- Placing blankets directly against extremely hot surfaces (use spacers)

- Folding or storing damp blankets (promotes mold and weakens fibers)

- Assuming one blanket provides complete protection (layer when needed)

- Using damaged blankets (compromised protection)

Where to Use Welding Blankets

Beyond welding, fire retardant welding blankets have multiple applications:

- Covering electrical panels near welding areas

- Protecting floors and walls in maintenance shops

- Creating temporary heat shields during metal cutting

- Covering flammable materials in construction sites

- Emergency fire containment (secondary use only)

Choosing the Right Blanket for Your Needs

Consider these factors when selecting fire retardant welding blankets:

- Your typical welding temperatures

- Size of your work area

- Frequency of use

- Types of materials you need to protect

- Storage space available

Quality fire retardant welding blankets are a smart investment for any welding operation. They prevent costly fires, protect valuable equipment, and most importantly - keep you safe. Always choose blankets rated for your specific welding applications and maintain them properly for reliable protection.